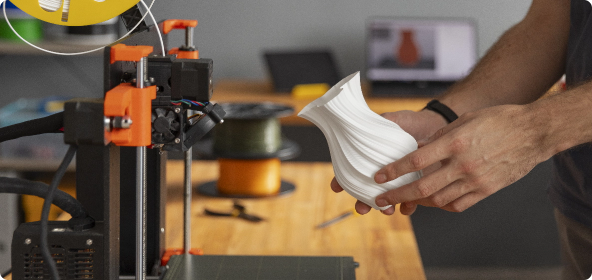

How to Improve 3D Scanning Surface Quality for Finer 3D Printing Results

3D scanning technology provides precise digital models for 3D printing, but poor scanning quality can result in rough surfaces, loss of detail, or even affect assembly accuracy. So, how can we improve surface quality during the 3D scanning process to achieve finer 3D printing results?

In this article, we will explore the factors affecting 3D scan quality and offer a comprehensive solution that covers pre-scan preparation, scanning techniques, and post-processing optimizations. These steps will help you achieve cleaner scan data, richer details, reduce repair work, and enhance the final 3D printing quality.

1. Key Factors Affecting 3D Scanning Surface Quality

Before optimizing scan quality, we need to understand the key factors that impact scanning results:

- Scanner Resolution: The higher the resolution, the more detailed the scan. However, this can also increase noise.

- Object Material: Materials that are smooth, transparent, or highly reflective can affect data acquisition and may require special treatment.

- Lighting Conditions: The intensity and direction of ambient light can interfere with scan quality.

- Scanning Method: Handheld scanning and fixed scanning have their pros and cons, and the way they are operated directly influences data quality.

- Post-Processing: Scan data often needs denoising, smoothing, and repair to improve final quality.

Next, we will delve into how to optimize each aspect.

2. Pre-Scan Preparation

2.1 Choose the Right Scanning Environment

A good scanning environment can significantly reduce errors and enhance data quality. Key considerations include:

- Avoid Direct Strong Light: Strong light can interfere with the scanner’s sensors and affect data capture. Try to scan in a soft, even lighting environment.

- Control Ambient Brightness: Too dark an environment can result in the scanner missing key features. Adding supplemental lighting can improve accuracy.

- Minimize Background Interference: Choose a background with a single color to avoid interference from other objects during scanning.

2.2 Pre-process the Object Being Scanned

Different materials can cause various issues during scanning. Therefore, some pre-scan treatment may be necessary:

- Reduce Reflection: For materials like metal or glass, use matte sprays or temporary coatings (e.g., talcum powder, baby powder) to reduce reflections and improve scan quality.

- Handle Transparent Objects: Transparent materials can make it hard for the scanner to detect surface shapes. Applying a matte spray or attaching frosted tape can improve scanning feasibility.

- Enhance Scan Features: If the object’s surface is too smooth or lacks distinct features, apply feature-point stickers to help the scanner align and improve data completeness.

3. Optimizing the Scanning Process

3.1 Choose the Right Scanning Method

Different scanning methods affect data quality in different ways:

- Handheld Scanning: Suitable for large objects, but you must move steadily to avoid shaking, as sudden movements can cause misalignment or data loss.

- Fixed Scanning: Ideal for small, detailed objects. Fix the scanner to a tripod and use a turntable to improve stability and accuracy.

3.2 Control Scanning Parameters

Adjusting scanning parameters can improve data quality:

- Adjust Exposure: If the object is too dark, increase the exposure slightly, but avoid overexposing and losing fine details.

- Set Resolution: For fine features, use a high-resolution mode, but be mindful that large file sizes may complicate processing.

- Scan Path Planning: Scan from multiple angles to cover the entire object and avoid unscanned areas or blind spots.

3.3 Ensure Precise Data Alignment

When scanning from different angles, the data needs to be stitched together to form a complete 3D model. To avoid alignment errors:

- Use Feature Point Matching: If the object has enough distinctive feature points, the software can automatically align the data.

- Manually Adjust Alignment: If automatic alignment fails, manually mark key points for correction.

- Minimize Multiple Scanning Segments: Reduce unnecessary segmented scanning and try to scan as much of the object in one go to improve alignment precision.

4. Post-Processing the Scanning Data

Even with perfect scanning, post-processing is often required to enhance surface quality and improve printability.

4.1 Denoising and Smoothing

- Remove Floating Noise: Use 3D software (such as Meshmixer, Blender) to remove isolated points floating outside the model.

- Smooth Surfaces: Use smoothing tools to reduce unnecessary surface noise, but avoid over-smoothing as it may erase fine details.

4.2 Repair Missing Data

If parts of the scanned model are missing, you can repair them using software:

- Automatic Filling: Use one-click repair functions to fill small gaps.

- Manual Repair: For larger missing areas, use modeling tools to manually fill in the gaps.

4.3 Retopology Optimization

- Reduce Polygon Count: Scan data often contains excessive triangle faces. Simplify the mesh to make the model more suitable for 3D printing.

- Optimize Topology: Use retopology tools to make the model’s surface more uniform, improving print quality.

5. Final Processing for 3D Printing

Once you’ve optimized the scan data, ensure the model is suitable for 3D printing:

- Check Model Closure: 3D printing requires the model to be closed. An open model will cause printing failures.

- Adjust Normals: Ensure that the normals are facing the correct direction to prevent surface errors during printing.

- Optimize Support Structures: If the model has overhanging parts, add adequate support structures to ensure stability during printing.

Conclusion

Improving the surface quality of 3D Scanning for 3D Printing requires attention to multiple aspects, including pre-scan preparation, process optimization, post-processing, and print adaptation. Each step of optimization helps make the scan data more accurate and clean, reducing the need for repairs and enhancing the final 3D printing quality.

Whether you are a beginner or an experienced 3D scanning enthusiast, the methods outlined in this article can help you improve scan quality and achieve finer 3D printing results. I hope these tips assist you in your journey through the world of 3D scanning and printing!

- Questions and Answers

- Opinion

- Motivational and Inspiring Story

- Technology

- Live and Let live

- Focus

- Geopolitics

- Military-Arms/Equipment

- Security

- Economy

- Beasts of Nations

- Machine Tools-The “Mother Industry”

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film/Movie

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Health and Wellness

- News

- Culture