Automation Revolutionizes Ei Transformer Manufacturing

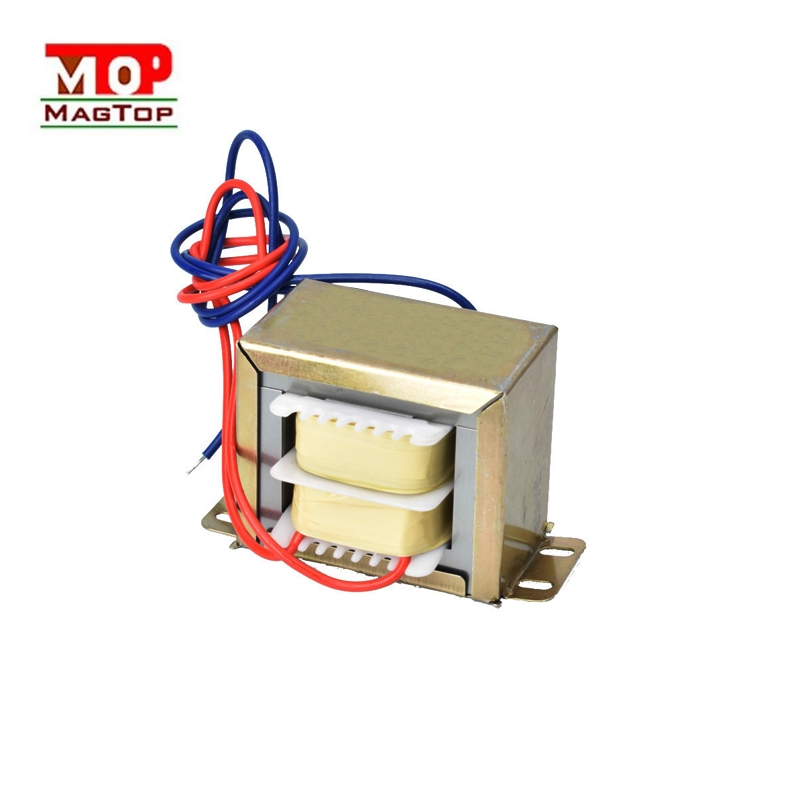

Automation is transforming the production of 220V to 12V low frequency transformers, bringing unprecedented improvements in quality, consistency, and cost-efficiency. Leading manufacturers are deploying fully automated winding machines, precision core assembly lines, and advanced quality control systems to improve production efficiency and product reliability.

These advances are particularly impactful for Ei transformers, where traditionally labor-intensive processes such as manual coil winding and varnishing are being replaced by high-speed robotic systems. This not only reduces human error but also enhances the consistency of key parameters such as winding tightness and insulation quality.

By integrating real-time data collection into the manufacturing process, companies can now monitor production quality continuously, ensuring that each 220V to 12V transformer meets stringent performance and safety standards.

- Questions and Answers

- Opinion

- Motivational and Inspiring Story

- Technology

- Live and Let live

- Focus

- Geopolitics

- Military-Arms/Equipment

- Sicurezza

- Economy

- Beasts of Nations

- Machine Tools-The “Mother Industry”

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film/Movie

- Fitness

- Food

- Giochi

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Altre informazioni

- Party

- Religion

- Shopping

- Sports

- Theater

- Health and Wellness

- News

- Culture