Automotive Applications of Radiator Fabrication in the Philippines

The automotive industry in the Philippines is growing rapidly, driven by increasing vehicle sales and evolving consumer demands. Among the essential components in vehicles, radiators play a vital role in ensuring optimal engine performance and safety. As the demand for high-quality radiators rises, local manufacturers are stepping up to meet these needs by offering innovative solutions. This article explores the opportunities, challenges, and trends shaping radiator fabrication in the Philippines.

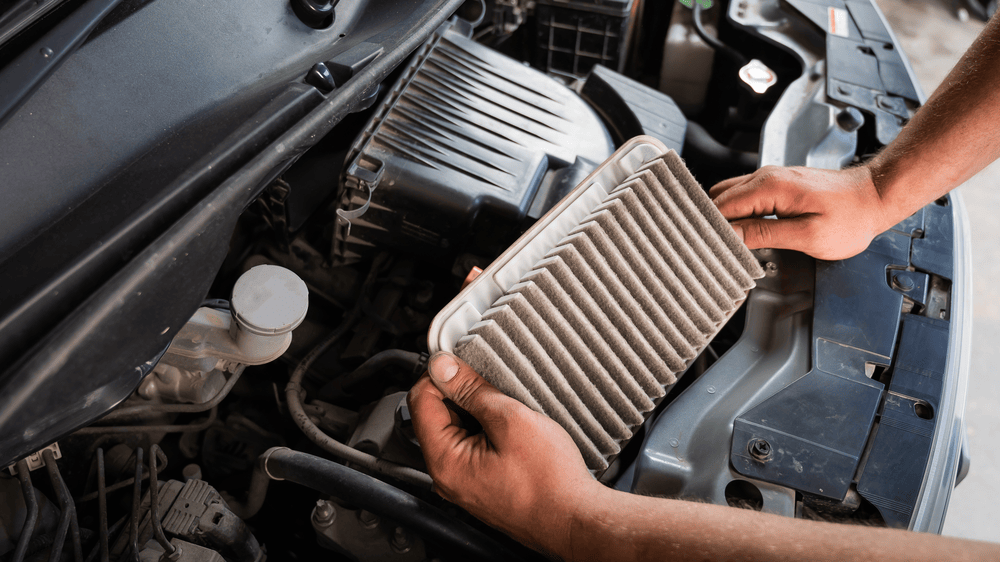

Introduction to Radiator Fabrication

Radiators prevent engines from overheating by dissipating heat through a cycle of coolant circulation. In tropical climates like the Philippines, where high temperatures can strain engine systems, efficient radiators are even more essential.

The Philippine automotive market has seen significant growth in recent years. In 2024 alone, vehicle sales increased by 21%, reflecting a surge in demand for automotive components, including radiators. Local manufacturers like Roberts AIPMC have taken advantage of this trend by producing high-quality radiators for both domestic and international markets.

Market Growth and Consumer Demand

The increasing number of vehicles on Philippine roads has led to a growing need for reliable and customizable radiator solutions. Consumers now seek radiators that not only enhance performance but also cater to specific aesthetic or functional preferences. Local fabricators are meeting these demands by offering tailored products with faster turnaround times compared to imported options.

Additionally, supply chain disruptions have made it challenging to source OEM parts internationally. This has created an opportunity for local manufacturers to fill the gap with high-quality alternatives that meet global standards.

Trends Shaping Radiator Fabrication

Sustainability and Eco-Friendly Technologies

As environmental concerns grow, the automotive industry is shifting toward sustainable technologies like electric vehicles (EVs). Unlike traditional vehicles, EVs require specialized cooling systems to manage battery temperatures effectively. This shift presents a unique opportunity for radiator manufacturers to innovate and design products tailored for EVs.

Government incentives promoting eco-friendly practices have further encouraged local manufacturers to adopt sustainable materials such as aluminum and plastic-aluminum composites. These materials are lightweight, corrosion-resistant, and fuel-efficient, making them ideal for modern radiator designs.

Export Potential and Global Trends

Globally, the automotive radiator market is projected to reach $19.8 billion by 2030, growing at an annual rate of 6.8%. This growth positions Filipino manufacturers to expand their presence in international markets. By adopting advanced manufacturing technologies like automation and robotics, local companies can improve efficiency and compete with global players.

The Asia-Pacific region offers significant export opportunities due to its rapidly expanding automotive industry. Filipino manufacturers can leverage their expertise and proximity to these markets to establish themselves as reliable suppliers of high-quality radiators.

Economic Impact of Radiator Fabrication

Supporting Local Industries

Radiator fabrication contributes significantly to the Philippine economy by creating jobs and supporting related industries such as metal fabrication and logistics. Companies like Roberts AIPMC exemplify this impact through their large-scale projects, such as building massive radiators for industrial applications like PASAR’s generator sets. These projects showcase the technical expertise and economic contributions of local manufacturers.

Workforce Development

To remain competitive, local manufacturers must invest in workforce development. Training programs focused on advanced manufacturing techniques equip workers with the skills needed to operate modern machinery and design innovative products. This not only boosts productivity but also fosters a culture of continuous improvement within the industry.

Challenges and Opportunities

While radiator fabrication in the Philippines shows great promise, it also faces challenges such as competition from imported products and limited access to advanced technologies. However, these challenges can be addressed through strategic investments in research and development (R&D) and partnerships with international firms. By focusing on innovation and quality, Filipino manufacturers can strengthen their position in both domestic and global markets.

Technological Advancements in Manufacturing

Adopting modern technologies is crucial for improving efficiency and reducing production costs. Automation and robotics enable manufacturers to produce consistent, high-quality radiators while minimizing errors. These advancements also allow companies to scale operations efficiently, meeting both local and international demand.

Moreover, innovations in radiator materials—such as hybrid designs combining brass-copper cores with aluminum fins—enhance durability while reducing weight. Such developments align with global trends toward lightweight automotive components that improve fuel efficiency.

Key Takeaway

Radiator fabrication in the Philippines is poised for significant growth as it aligns with current trends in sustainability, customization, and technological innovation. The country’s growing automotive market presents numerous opportunities for local manufacturers to expand their operations and explore export potential within the Asia-Pacific region.

By investing in advanced manufacturing technologies, workforce training, and eco-friendly practices, Filipino companies can position themselves as leaders in this dynamic industry. As they adapt to evolving consumer needs and environmental challenges, they will play a crucial role in shaping the future of radiator fabrication both locally and globally.

Radiator fabrication is not just an industrial activity but a vital contributor to the Philippine economy’s growth story. With continued innovation and collaboration among stakeholders—including policymakers, investors, and manufacturers—the industry is well-equipped to thrive in an increasingly competitive landscape.

- Questions and Answers

- Opinion

- Motivational and Inspiring Story

- Technology

- Live and Let live

- Focus

- Geopolitics

- Military-Arms/Equipment

- Securitate

- Economy

- Beasts of Nations

- Machine Tools-The “Mother Industry”

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film/Movie

- Fitness

- Food

- Jocuri

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Alte

- Party

- Religion

- Shopping

- Sports

- Theater

- Health and Wellness

- News

- Culture