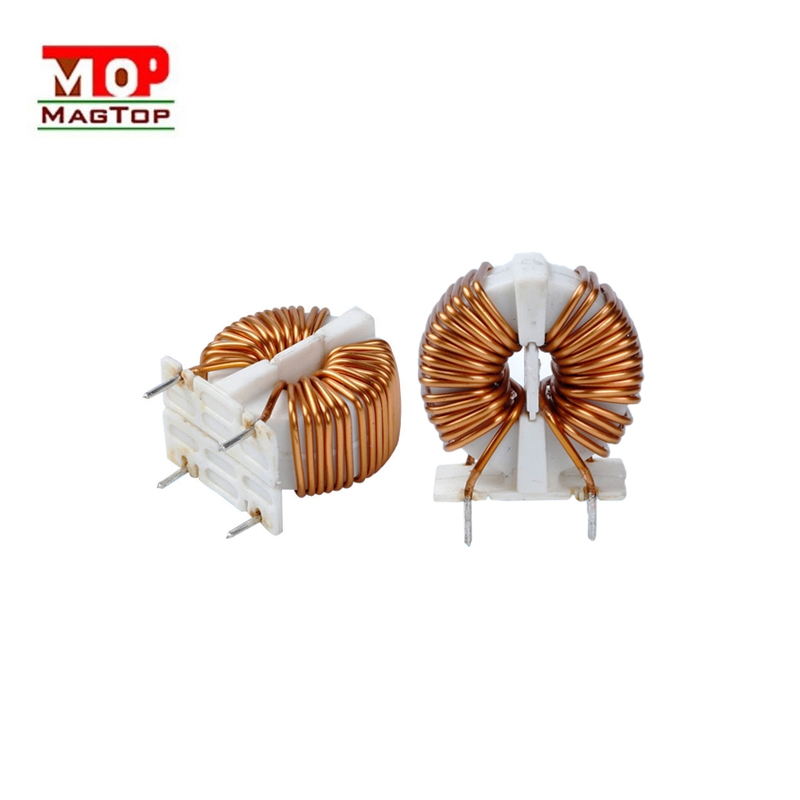

Toroidal Power Inductors: The Unsung Heroes of Next-Gen Electric Vehicles

As electric vehicles (EVs) evolve, automakers are turning to toroidal power inductors to solve critical challenges in power delivery, efficiency, and thermal management.

Why Toroidal Inductors Are Ideal for EVs EV power systems demand components that can handle high currents, high frequencies, and extreme temperatures—all while minimizing energy loss.

Toroidal inductors excel in these areas due to their:

Low EMI emissions (critical for vehicle safety and compliance) Superior thermal dissipation (reducing overheating risks) Compact, space-saving design (vital for densely packed EV electronics)

are now using these inductors in:

Onboard chargers (for faster AC/DC conversion)

DC-DC converters(to manage battery voltage)

Battery management systems (BMS) (for precise energy regulation)

Case Study:

Tesla’s Next-Gen Powertrain A teardown of Tesla’s 4680 battery pack revealed custom toroidal inductors in its power distribution module. Engineers noted that these components help reduce energy loss by 12-15% compared to traditional designs, directly improving range.

Market Growth and Key Players According to Yole Développement, the global market for toroidal inductors in EVs will grow at a CAGR of 18% from 2024 to 2030. Leading suppliers like Vishay, Würth Elektronik, and Murata are expanding production to meet demand.

Challenges Ahead:

While toroidal inductors offer clear benefits, their higher manufacturing cost remains a hurdle. However, economies of scale and new automated winding techniques are expected to drive prices down.

- Questions and Answers

- Opinion

- Motivational and Inspiring Story

- Technology

- Live and Let live

- Focus

- Geopolitics

- Military-Arms/Equipment

- Seguridad

- Economy

- Beasts of Nations

- Machine Tools-The “Mother Industry”

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film/Movie

- Fitness

- Food

- Juegos

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Health and Wellness

- News

- Culture