Friction Stir Welding Equipment Market Size Share Growth Report 2025

IMARC Group, a leading market research company, has recently released a report titled “Friction Stir Welding Equipment Market Report by Equipment Type (Mobile Friction Stir Welding Equipment, Fixed Friction Stir Welding Equipment, and Others), End-Use Industry (Automotive Industry, Aerospace Industry, Railway Industry, Shipbuilding Industry, and Others), and Region 2025-2033”. The study provides a detailed analysis of the industry, including the global friction stir welding equipment market share, size, and industry growth forecast. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

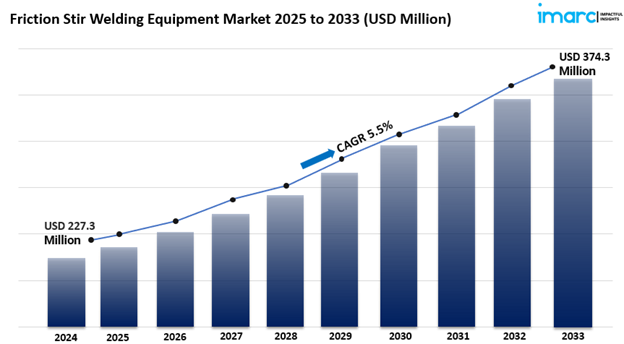

The global friction stir welding equipment market size reached USD 239.9 Million in 2024. Looking forward, IMARC Group expects the market to reach USD 389.3 Million by 2033, exhibiting a growth rate (CAGR) of 5.25% during 2025-2033.

Request to Get the Sample Report:

https://www.imarcgroup.com/friction-stir-welding-equipment-market/requestsample

Friction Stir Welding Equipment Market Trends

The friction stir welding equipment market is undergoing significant transformation, driven by several key trends that reflect the changing landscape of manufacturing. One prominent trend is the increasing adoption of FSW technology across diverse industries, including aerospace, automotive, and renewable energy. By 2025, it is expected that the versatility of friction stir welding will lead to its expanded use in new applications, such as the production of lightweight components for electric vehicles and advanced manufacturing processes in the aerospace sector.

Additionally, there is a growing emphasis on automation and robotics within the FSW market, as manufacturers seek to enhance productivity and reduce labor costs. The integration of automated systems is enabling more efficient and consistent welding operations, which is crucial for meeting the demands of high-volume production environments.

Furthermore, the trend towards customization and flexibility in manufacturing is driving the development of modular FSW equipment that can be easily adapted for various applications. As these trends evolve, the friction stir welding equipment market is set to experience significant growth, with companies increasingly focusing on innovation and sustainability to meet the diverse needs of their customers.

Market Dynamics of the Friction Stir Welding Equipment Market

Increasing Demand for Lightweight Materials in Manufacturing

The friction stir welding (FSW) equipment market is experiencing robust growth driven by the increasing demand for lightweight materials, particularly in industries such as aerospace, automotive, and shipbuilding. As manufacturers strive to enhance fuel efficiency and reduce emissions, they are increasingly turning to lightweight materials like aluminum and magnesium alloys. FSW is particularly well-suited for joining these materials due to its ability to produce high-strength, defect-free welds without compromising the material properties.

By 2025, the trend towards lightweight construction will continue to accelerate, prompting manufacturers to invest in advanced FSW equipment that can handle diverse materials and complex geometries. The aerospace sector, for instance, is expected to be a major driver of this demand as aircraft manufacturers seek to reduce weight while maintaining structural integrity.

Additionally, the automotive industry is increasingly adopting FSW for electric vehicle (EV) production, where lightweight components are essential for maximizing performance and range. This growing focus on lightweight materials is set to significantly boost the friction stir welding equipment market as companies seek innovative solutions to meet evolving industry standards.

Technological Advancements in Welding Equipment

Technological innovations are fundamentally transforming the friction stir welding equipment market, leading to enhanced performance, efficiency, and versatility. Recent advancements in automation, robotics, and control systems are enabling manufacturers to achieve higher precision and consistency in welding processes. By 2025, it is anticipated that the integration of smart technologies, such as artificial intelligence and machine learning, will further optimize FSW operations by providing real-time monitoring and adaptive control capabilities. These innovations allow for improved process parameters, resulting in better weld quality and reduced production times.

Furthermore, the development of portable and compact FSW equipment is expanding the applicability of this technology to a wider range of industries, including construction and maintenance. As manufacturers continue to invest in R&D to enhance their FSW offerings, the market is likely to see a surge in demand for advanced welding solutions that can meet the specific needs of various applications. This technological evolution is not only driving market growth but also fostering competitive advantages for companies that embrace these innovations.

Growing Focus on Sustainability and Eco-Friendly Manufacturing

The friction stir welding equipment market is increasingly influenced by the global emphasis on sustainability and eco-friendly manufacturing practices. As industries face mounting pressure to reduce their carbon footprints and adopt greener technologies, FSW presents a compelling solution due to its energy efficiency and minimal waste generation. Unlike traditional welding methods, FSW does not require filler materials or shielding gases, significantly reducing the environmental impact of the welding process. By 2025, it is expected that more companies will adopt FSW as part of their sustainability initiatives, particularly in sectors such as automotive and aerospace, where regulatory pressures are intensifying.

Additionally, the lightweight structures produced through FSW contribute to overall energy savings in end-use applications, further aligning with global sustainability goals. Manufacturers are increasingly highlighting the eco-friendly attributes of FSW technology in their marketing efforts, appealing to environmentally conscious consumers and businesses. As the trend towards sustainable manufacturing continues to gain traction, the friction stir welding equipment market is poised for substantial growth, driven by the demand for greener production methods.

Friction Stir Welding Equipment Market Report Segmentation:

Breakup By Equipment Type:

· Mobile Friction Stir Welding Equipment

· Fixed Friction Stir Welding Equipment

· Others

Based on the equipment type, the market has been classified into mobile friction stir welding equipment, fixed friction stir welding equipment, and others.

Breakup By End-Use Industry:

· Automotive Industry

· Aerospace Industry

· Railway Industry

· Shipbuilding Industry

· Others

On the basis of end-use industry, the market has been divided into automotive industry, aerospace industry, railway industry, shipbuilding industry, and others.

Breakup By Region:

· North America

· Asia Pacific

· Europe

· Latin America

· Middle East and Africa

Region-wise, the market has been segmented into North America (United States and Canada), Asia Pacific (China, Japan, India, South Korea, Australia, Indonesia, and others), Europe (Germany, France, the United Kingdom, Italy, Spain, Russia, and others), Latin America (Brazil, Mexico, and others), and the Middle East and Africa.

Top Friction Stir Welding Equipment Market Leaders:

The friction stir welding equipment market research report outlines a detailed analysis of the competitive landscape, offering in-depth profiles of major companies.

Some of the key players in the market are:

· Beijing FSW Technology Co. Ltd.

· Colfax Corporation

· Fooke GmbH

· Gatwick Technologies Ltd.

· General Tool Company

· Grenzebach Maschinenbau GmbH

· Hitachi High-Tech Corporation

· KUKA Systems GmbH (Midea Group Co. Ltd.)

· Manufacturing Technology Inc.

· Par Systems LLC

Ask Analyst for Customized Report:

https://www.imarcgroup.com/request?type=report&id=2279&flag=C

Key Highlights of the Report:

· Market Performance (2019-2024)

· Market Outlook (2025-2033)

· Market Trends

· Market Drivers and Success Factors

· Impact of COVID-19

· Value Chain Analysis

If you need specific information that is not currently within the scope of the report, we will provide it to you as a part of the customization.

About Us

IMARC Group is a leading market research company that offers management strategy and market research worldwide. We partner with clients in all sectors and regions to identify their highest-value opportunities, address their most critical challenges, and transform their businesses.

IMARC’s information products include major market, scientific, economic and technological developments for business leaders in pharmaceutical, industrial, and high technology organizations. Market forecasts and industry analysis for biotechnology, advanced materials, pharmaceuticals, food and beverage, travel and tourism, nanotechnology and novel processing methods are at the top of the company’s expertise.

Contact Us:

IMARC Group

134 N 4th St

Brooklyn, NY 11249, USA

Website: imarcgroup.com

Email: sales@imarcgroup.com

Americas: +1-631-791-1145

- Questions and Answers

- Opinion

- Motivational and Inspiring Story

- Technology

- Live and Let live

- Focus

- Geopolitics

- Military-Arms/Equipment

- Security

- Economy

- Beasts of Nations

- Machine Tools-The “Mother Industry”

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film/Movie

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Health and Wellness

- News

- Culture