ABS Plastic Sheet Offers Strength For Diverse Solutions

Understanding the Benefits and Uses of a Highly Versatile Thermoplastic

Acrylonitrile butadiene styrene has made an impressive mark on the capabilities of modern manufacturing and design, compared to most other materials today it stands alone in its presence. Due to its strength, toughness, and versatility, acrylonitrile butadiene styrene is utilized in a number of industries including the automotive, construction, and electronic industries. The properties of acrylonitrile butadiene styrene allow for a number of functional and esthetic applications.

Why Durability and Finish Matter in Fabrication

The Black Smooth ABS Sheet is undoubtedly the most popular type of thermoplastic on the market today. These sheets are commonly used in industrial applications where visual appearance and strength are two important factors. Who would not want a NICE looking product housing, side panels, enclosures, etc., that provide long-lasting protection from damage? Beyond that, it also can be printed on, painted, or bonded to, which makes it often an excellent choice for signage and point-of-sale displays where visual appeal is a big driver for engagement with customers.

Color Customization and Industry Appeal

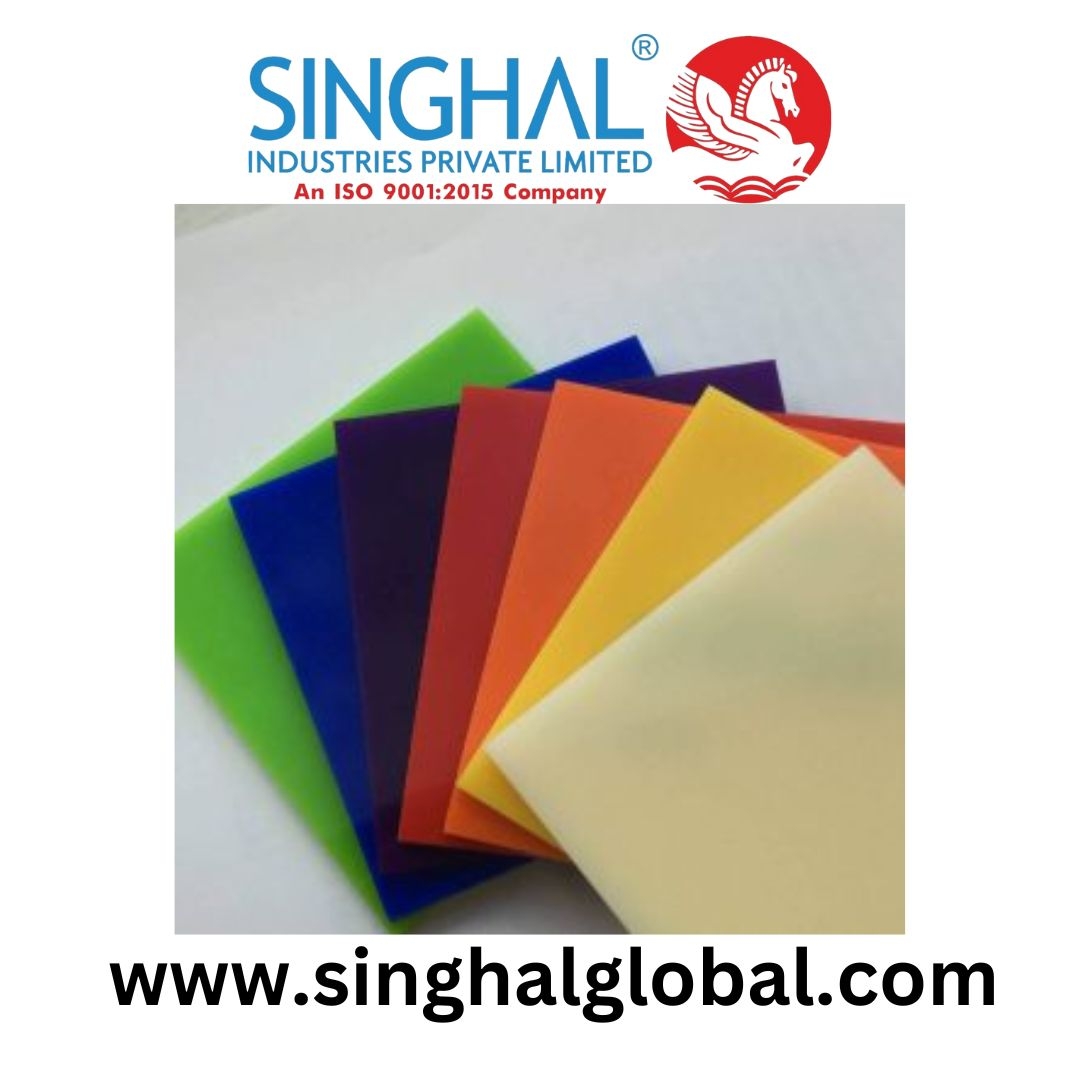

Having the ability to customize in color now opens an entirely new level to the usability of the material. Designers and manufacturers now consistently use colored options in ABS plastic sheets to meet brand standards or improve the cosmetics of the end product. These sheets can be offered in a vast array of colors, ranging from conservative pastels to bright focal points, providing a large range of opportunity to be creative. Color does not diminish performance, offering the same shipment of impact resistance, machinability, and thermal stability of the base material. These alternatives are frequently applied to areas related to interiors, children’s products, and consumer retail design.

Significance of Bright Hues in Safety and Branding

Of the available options, the red ABS plastic sheet is becoming popular for applications that require visibility and attention. Bright red is commonly used in the field of safety signage, emergency equipment housings, and branded products when stunning visual effect and character is required. Red is also a preferred look in automotive interiors and custom enclosures where a shop may want visitors to take notice.

Industrial and Creative Applications in Modern Design

In transportation, it often finds its way into dashboards, trim, protective hatch panels and more. Additionally, within construction, it is used for decorative wall panels and covers due to its lightweight and strong qualities. Artists and makers often use it for custom molds, prototypes and 3D models. The different finishes, including matte and gloss, color options, and positiveness of black smooth ABS sheet and Colored ABS Plastic Sheet makes for unlimited design possibilities in all industries.

Environmental Considerations and Sustainability Trends

As sustainability becomes more as a part of society, manufacturers are investigating the options for sustainable practices during the production of thermoplastics. Many manufacturing facilities are now using recycled material in producing their sheets and films with no reduced performance. Sustainable practices have allowed manufacturers to continue to drive down waste and establish circular economies in the plastics industry. More consumers and businesses are looking to source from companies whose practices are green, and there are pressures on producers to make new materials available and also utilize energy efficient manufacturing practices.

Global Supply Chains and Production Leadership

With burgeoning demand, the value chain for this adaptable plastic is growing quickly all over the world. Of course, there are many companies producing and distributing it, but there is still a sense of wonder about the most common question: who produces the most ABS plastic sheet? The name will depend on regional leaders and production amount; typically leading spruced makers are those with a thriving distribution channel around the globe, continuous research and development and strong quality control. Additionally, the biggest companies commonly serve large connected industries like automotive and electronics, further solidifying their top status in the industry.

Conclusion

In both heavy industrial applications and fun creative consumer objects, the unique combination of strength, aesthetic appeal, and customizable nature of ABS makes it a crucial material. The ever-increasing variety of finishes and color options, like the Red ABS Plastic Sheet and black smooth ABS sheet, helps extend the use cases and allow for aesthetic requirements to be met. As industry transitions to sustainable practices and continues to inspire innovation, it is clear that this thermoplastic will still be a foundational material in both modern and future manufacturing environments.

Frequently Asked Questions

What makes this thermoplastic perfect for industrial applications?

Its impact resistance, thermal stability, and ability to be machined makes it perfect for harsh environments and precision machining. It's relatively light weight, and easy to bond, cut or form.

Who is the largest manufacturer of ABS Plastic Sheet?

ABS plastic sheet products are equally as strong and durable as the standard versions. Pigmentation is uniform throughout the material, so there are no areas of weaker colors or variations in performance.

Where are the red sheets widely utilized?

The red ABS plastic sheet is most commonly used in safety equipment, emergency systems, automotive design, and to create brand differentiation in consumer goods requiring a bright, highly visible finish.

- Questions and Answers

- Opinion

- Motivational and Inspiring Story

- Technology

- Live and Let live

- Focus

- Geopolitics

- Military-Arms/Equipment

- Безопасность

- Economy

- Beasts of Nations

- Machine Tools-The “Mother Industry”

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film/Movie

- Fitness

- Food

- Игры

- Gardening

- Health

- Главная

- Literature

- Music

- Networking

- Другое

- Party

- Religion

- Shopping

- Sports

- Theater

- Health and Wellness

- News

- Culture