Manufacturer's Look at Fashion vs. Sport Swimwear

The hum of sewing machines and the vibrant colors of fabric rolls are the soundtrack to our days. To the casual observer, a swimsuit might seem like a simple garment. But from our perspective behind the scenes, we know that not all swimwear is created equal. The journey from a design sketch to a finished product is vastly different depending on its ultimate purpose. As swimwear manufacturers, we navigate these two distinct worlds every day. Let's pull back the curtain and explore the fundamental differences in how fashion swimwear and sports swimwear are produced.

1. The Foundation: Fabric Selection

Everything starts with the fabric. This single choice dictates the look, feel, and, most importantly, the performance of the final garment.

For fashion pieces, the focus is on aesthetics and luxurious feel. We work with a wide array of materials chosen for their visual appeal. This includes soft, ribbed textures, high-sheen fabrics that catch the sunlight, and delicate materials like crochet or velvet-effect spandex blends. While these fabrics are designed to handle a dip in the pool, their primary job is to look stunning. Chlorine resistance is a factor, but it often takes a backseat to the novelty, print clarity, and unique texture of the material. Recycled nylon fabrics are also a popular and sustainable choice in this category.

Production for performance swimwear begins with a rigorous fabric selection process centered on technical specifications. The priority is durability and function. We exclusively use high-performance blends, most commonly PBT (Polybutylene terephthalate) and engineered Lycra® blends like Xtra Life Lycra®. These fabrics offer superior chlorine resistance, essential for enduring hours in a pool. They are also chosen for properties like muscle compression, low water absorption, pilling resistance, and a high UV protection factor (UPF). The fabric must feel like a second skin, providing support without restricting movement.

2. The Blueprint: Pattern Making and Cut

The silhouette of a swimsuit is its identity. The patterns we create are tailored to vastly different end-goals.

Our pattern makers have creative freedom to follow and set trends. This is where you see intricate designs: asymmetrical necklines, dramatic cut-outs, high-cut legs, and complex strapping. The patterns must account for non-functional elements like ruffles, ties, and ruching. A significant amount of time is spent ensuring the piece is flattering on a stationary body, prioritizing style and visual lines over pure functionality.

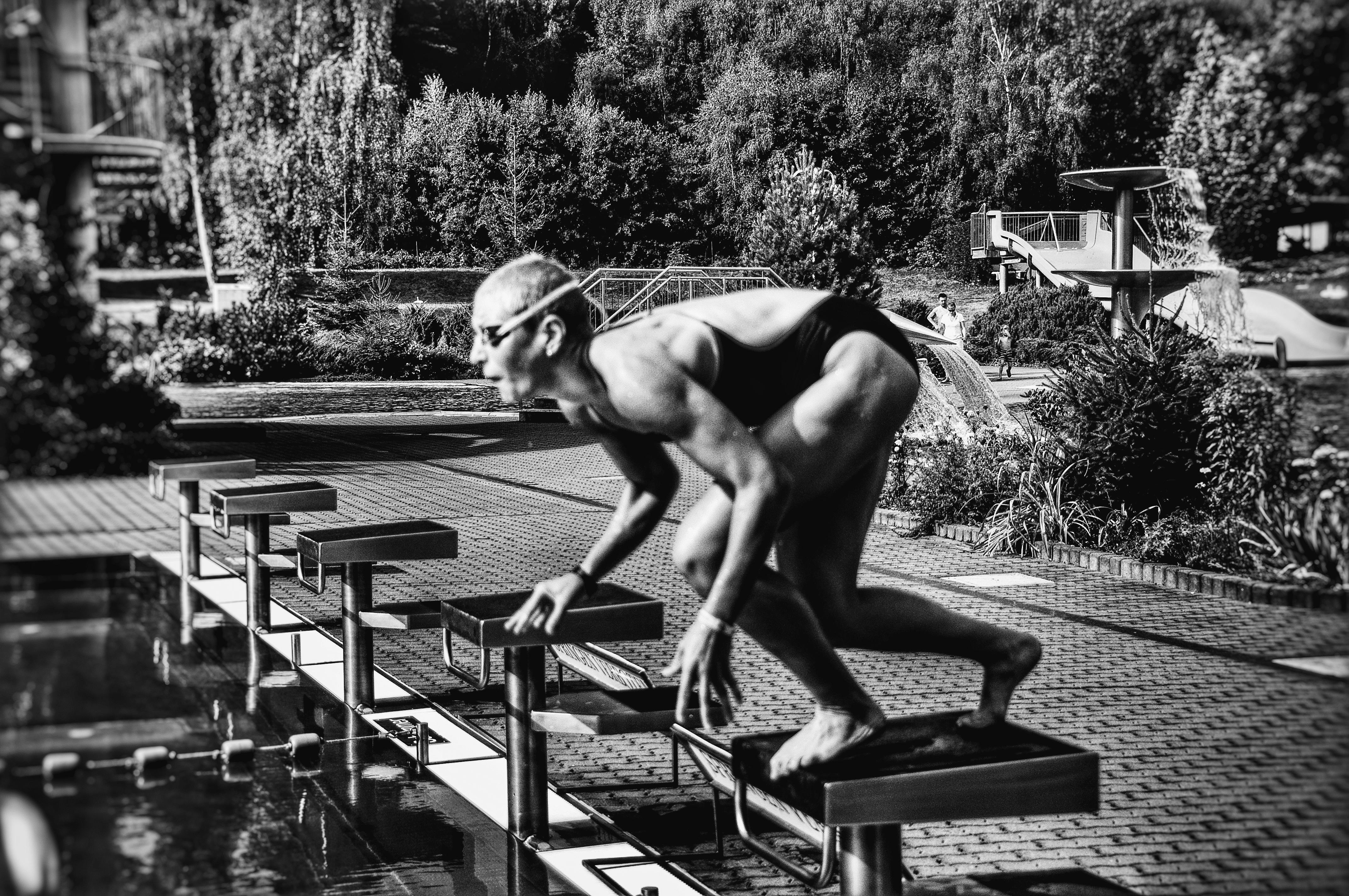

In contrast, patterns for sports swimwear are born from ergonomics and hydrodynamics. The goal is to minimize drag and maximize freedom of movement. We design features like open racerbacks or keyholes that allow for full shoulder rotation. The cut provides secure, full coverage to ensure the suit stays in place during intense activity like dives and flip-turns. Every seam and curve is there for a reason, tested to enhance performance, not just to follow a trend.

3. The Assembly: Stitching and Construction

How a suit is pieced together is crucial for its comfort and lifespan. The techniques we use differ significantly.

For fashion swimwear, standard stitching techniques like overlocking are common. The main goal is a clean, polished finish where seams are often hidden for a sleek look. We may incorporate underwires, boning, or removable pads, which requires more complex internal construction similar to lingerie. While the seams are strong, they aren't necessarily designed to withstand the repetitive, high-stress motion of athletic swimming.

For sports swimwear, construction is all about durability and comfort. We rely on specialized, high-stress stitching. Flatlock seams are a signature of performance swimwear; they lie flat against the skin to eliminate chafing during repetitive movements. We also use reinforced bar tacks at critical stress points, such as where straps meet the body of the suit, to prevent tearing. The entire garment is built to endure constant stretching and exposure to chemically treated water without losing its shape or integrity.

From fabric to final stitch, every step in the manufacturing process is a deliberate choice. Whether crafting a head-turning bikini or an elite racing suit, we take pride in the specific engineering required for each.

- Questions and Answers

- Opinion

- Motivational and Inspiring Story

- Technology

- True & Inspiring Quotes

- Live and Let live

- Focus

- Geopolitics

- Military-Arms/Equipment

- Sécurité

- Economy/Economic

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film/Movie

- Fitness

- Food

- Jeux

- Gardening

- Health

- Domicile

- Literature

- Music

- Networking

- Autre

- Party

- Religion

- Shopping

- Sports

- Theater

- Health and Wellness

- News

- Culture