Shop Drawing in Construction: Your Complete Guide to Success

Construction projects are complex puzzles with thousands of moving parts. One missing piece can derail timelines, inflate budgets, and compromise safety. Shop drawings serve as the critical bridge between architectural vision and real-world construction, transforming conceptual designs into precise, buildable instructions.

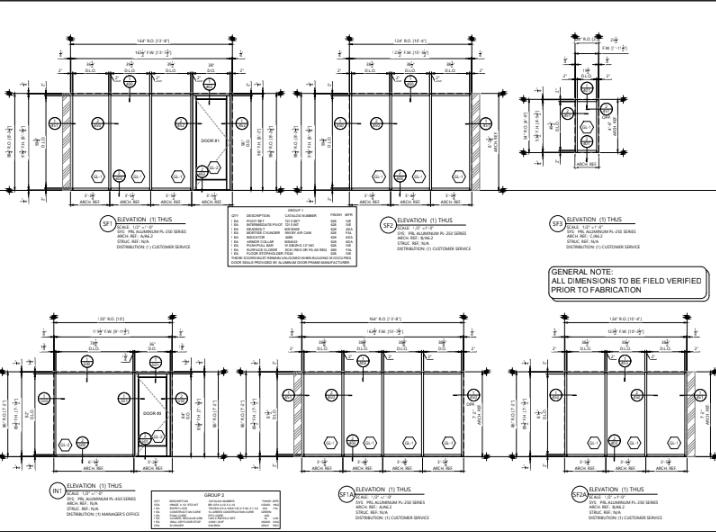

These detailed technical documents go far beyond basic blueprints. They provide contractors, fabricators, and installers with the specific information needed to manufacture and install building components correctly. From structural steel beams to HVAC ductwork, shop drawings ensure every element fits perfectly within the larger construction framework.

Understanding shop drawing in construction isn't just important—it's essential for project success. Whether you're a contractor, architect, or project manager, mastering this process can mean the difference between a smooth project delivery and costly delays.

Why Shop Drawings Matter in Modern Construction

Shop drawings function as the construction industry's quality control checkpoint. They catch potential conflicts before expensive materials are ordered or fabricated, saving projects from costly rework and schedule delays.

Consider a commercial office building where structural steel, electrical conduits, and HVAC systems must all occupy the same ceiling space. Without detailed shop drawings, these systems might conflict during installation, requiring expensive modifications or redesign work. Shop drawings identify these conflicts early, when solutions are still cost-effective.

These documents also serve legal purposes. They establish clear expectations between parties and provide documentation of what was approved for construction. This protects both contractors and owners when disputes arise about project specifications or performance.

Beyond conflict resolution, shop drawings improve communication across project teams. They translate the architect's design intent into language that fabricators and installers understand, reducing misinterpretation and ensuring consistent quality.

The Shop Drawing Process: From Concept to Approval

The shop drawing process follows a systematic workflow that typically spans several weeks or months, depending on project complexity.

Initial Review and Planning

Contractors begin by thoroughly reviewing contract documents, including architectural drawings, specifications, and engineering plans. They identify which building components require shop drawings and establish submission schedules that align with project milestones.

Drawing Development

Specialized drafters or engineers create detailed shop drawings using computer-aided design (CAD) software. These drawings show exact dimensions, materials, connections, and installation methods for specific building components. Unlike architectural drawings that show overall design intent, shop drawings focus on individual elements with manufacturing-level detail.

Internal Quality Control

Before external submission, contractors perform internal reviews to verify accuracy, completeness, and compliance with project specifications. This step catches errors early and reduces the likelihood of rejections during formal review.

Formal Submission and Review

Shop drawings are submitted to the architect or engineer of record for review and approval. Reviewers check for compliance with design intent, specifications, and applicable codes. They may approve, approve with corrections, or reject drawings requiring resubmission.

Revision and Resubmission

When corrections are required, contractors revise drawings and resubmit them for additional review. This cycle continues until approval is granted.

Final Approval and Fabrication

Once approved, shop drawings become the official fabrication and installation documents. Manufacturers use them to produce building components, and installers reference them during construction.

Key Players in Shop Drawing Success

Multiple stakeholders contribute to effective shop drawing processes, each bringing specialized expertise.

General Contractors coordinate overall shop drawing schedules and ensure timely submissions that support project timelines. They manage the flow of information between design teams and specialty contractors.

Specialty Contractors and Fabricators create shop drawings for their specific trades. Steel fabricators develop structural shop drawings, while mechanical contractors prepare HVAC shop drawings. Their deep technical knowledge ensures drawings reflect real-world fabrication and installation requirements.

Architects and Engineers review shop drawings for compliance with design intent and project specifications. They possess the authority to approve or reject submissions and often coordinate between different building systems to resolve conflicts.

Project Managers track shop drawing schedules, monitor approval status, and escalate issues that could impact project timelines. They serve as communication hubs between all parties involved in the process.

CAD Technicians and Drafters create the actual technical drawings using specialized software. Their skills in both drafting technology and construction methods directly impact drawing quality and accuracy.

Benefits of Accurate Shop Drawings

Investing in high-quality shop drawings pays dividends throughout the construction process.

Error Prevention represents the most significant benefit. Detailed shop drawings catch design conflicts, dimensional errors, and specification inconsistencies before they become field problems. This prevents costly rework and keeps projects on schedule.

Improved Fabrication Quality results from precise drawings that leave no room for interpretation. Fabricators can produce components that fit perfectly during installation, reducing field adjustments and improving overall construction quality.

Enhanced Project Coordination occurs when all trades have clear, detailed information about their work and how it interfaces with other building systems. This reduces conflicts between trades and improves installation sequencing.

Better Cost Control stems from accurate material quantities and specifications provided in shop drawings. This enables more precise purchasing and reduces waste from ordering incorrect or incompatible materials.

Faster Installation becomes possible when installers have detailed drawings showing exact placement, connections, and sequencing. This reduces field questions and delays while improving productivity.

Common Challenges and Practical Solutions

Despite their importance, shop drawing processes face several recurring challenges that can impact project success.

Schedule Compression often pressures teams to rush shop drawing development and review. This increases error rates and can lead to more extensive revision cycles. The solution involves realistic scheduling that accounts for proper development and review time, along with early identification of critical path items.

Communication Gaps between design teams and contractors can result in shop drawings that meet technical requirements but miss design intent. Regular coordination meetings and clear communication protocols help bridge these gaps.

Technology Integration challenges arise when different parties use incompatible software or file formats. Establishing standard formats and collaboration platforms early in the project prevents these issues.

Resource Constraints can limit the availability of qualified drafters and reviewers, creating bottlenecks in the process. Forward planning and resource allocation help ensure adequate staffing for shop drawing activities.

Quality Control Variations occur when different parties apply inconsistent review standards. Developing clear review criteria and checklists helps maintain consistent quality across all submissions.

Building Success Through Better Shop Drawings

Shop drawing in construction represents far more than a regulatory requirement—it's a strategic investment in project success. These detailed documents serve as the foundation for quality construction, enabling better coordination, reducing errors, and ensuring that architectural vision becomes built reality.

The most successful construction projects recognize shop drawings as collaborative tools that bring together diverse expertise to solve complex technical challenges. By investing in proper shop drawing processes, project teams can avoid costly mistakes, improve quality, and deliver projects that meet or exceed expectations.

Moving forward, consider how your organization can strengthen its shop drawing processes. Whether through better technology adoption, improved communication protocols, or enhanced quality control measures, small improvements in shop drawing management often yield significant project benefits.

- Questions and Answers

- Opinion

- Motivational and Inspiring Story

- Technology

- Live and Let live

- Focus

- Geopolitics

- Military-Arms/Equipment

- Security

- Economy

- Beasts of Nations

- Machine Tools-The “Mother Industry”

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film/Movie

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Health and Wellness

- News

- Culture