revopoint 3d camera

Three-dimensional vision has moved from research labs into the heart of industry. From guiding robots on the factory floor to preserving fragile cultural artifacts, 3D cameras are enabling applications that traditional 2D imaging cannot address. By capturing depth information alongside color and texture, these devices unlock new possibilities across multiple fields. Among the available options, the revopoint 3d camera illustrates how compact, high-precision sensors are being deployed to solve real-world challenges.

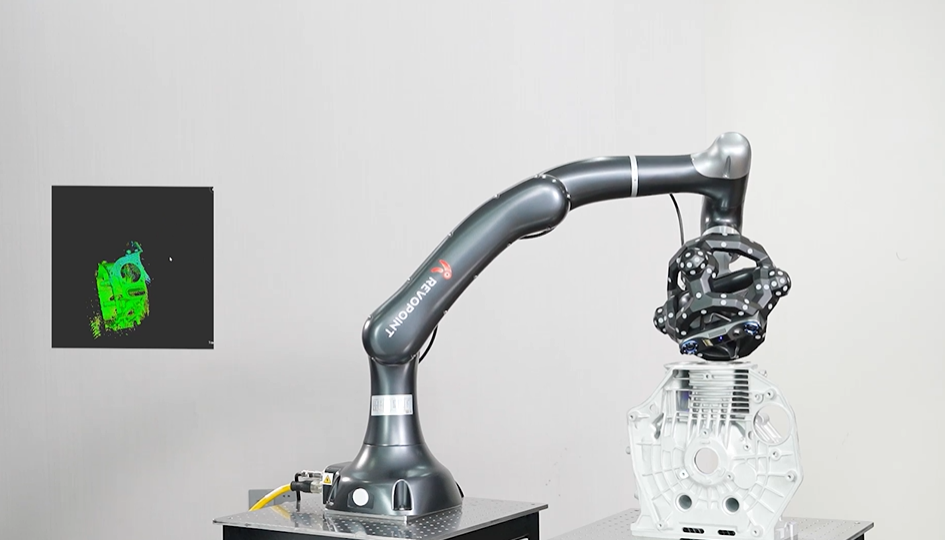

Smart Manufacturing and Industrial Automation

Factories increasingly rely on automation to meet rising demand and shrinking tolerances. Robots equipped with 3D vision can identify objects in cluttered environments, guide arms for pick-and-place, and adjust to unexpected part positions. Unlike 2D cameras, which only deliver flat images, depth cameras provide geometry and scale, allowing automation systems to “understand” space.

In automotive production, for example, 3D cameras are widely used for weld seam tracking and part alignment. They reduce downtime caused by manual calibration and ensure higher accuracy in repetitive tasks. Systems similar to the revopoint 3d camera are often integrated into robotic cells to support this transition.

Enhancing Quality Control

Quality assurance is one of the most demanding areas in manufacturing. Detecting surface defects, measuring deviations, or verifying dimensions at speed requires both precision and robustness. Traditional manual inspection can miss subtle irregularities, while coordinate measuring machines (CMMs) are often too slow for inline checks.

3D cameras fill this gap. By capturing full point clouds, they allow for automated deviation analysis and real-time feedback. Electronics manufacturers use them to detect warpage on circuit boards, while aerospace companies employ them to confirm structural panel tolerances. The ability to automate such checks helps industries scale without proportionally increasing human inspectors.

Reverse Engineering and Design Innovation

Legacy parts often lack digital documentation. Reverse engineering is the process of creating CAD models from physical objects, and 3D cameras accelerate it significantly. Instead of manually modeling or stitching incomplete scans, engineers can capture detailed geometry quickly.

A robot-mounted depth camera can follow precise trajectories, ensuring full coverage of complex objects. The resulting datasets support design modifications, product improvements, and rapid prototyping. This has proven especially useful in industries where tooling and parts must be recreated after decades of use.

Medical and Healthcare Applications

Healthcare is a field where accuracy directly impacts lives. Custom implants, dental prostheses, and orthopedic devices must match patient anatomy with precision. 3D cameras allow non-invasive capture of body surfaces, feeding data into CAD and manufacturing systems.

Surgeons also rely on depth cameras for surgical planning and navigation. Real-time imaging provides spatial awareness that enhances minimally invasive procedures. Compact industrial-grade systems, such as the revopoint 3d camera, are increasingly considered in labs and clinics for these demanding applications.

Preserving Cultural Heritage

Cultural institutions are using 3D scanning to digitize artifacts and make collections accessible worldwide. Traditional photography cannot capture the depth and texture of fragile objects, while manual handling risks damage.

3D cameras mounted on robotic arms or fixed rigs capture detailed geometry from multiple angles without physical contact. This makes it possible to archive statues, pottery, or manuscripts in true 3D form. Digital replicas support conservation, education, and even 3D-printed reproductions for exhibitions.

Expert Perspectives

Leaders in robotics and automation often highlight perception as the foundation of progress. As one researcher observed, “Robots can only be as capable as their vision allows.” With 3D cameras providing spatial intelligence, industries are closing the gap between automation and human-like perception.

Community discussions reinforce this. On professional forums, engineers note that depth cameras improved defect detection rates dramatically once integrated into production lines. The rise of solutions like the revopoint 3d camera illustrates how accessible hardware is making advanced vision more mainstream.

Best Practices for Integration

Deploying 3D vision requires more than hardware installation. Key considerations include:

-

Calibration and alignment: Accurate results depend on consistent calibration with robotic arms or fixtures.

-

Surface challenges: Glossy, transparent, or dark surfaces may need treatment or adaptive scanning strategies.

-

Lighting conditions: While many cameras are resistant to ambient interference, controlled lighting improves data quality.

-

Data integration: The greatest value comes when depth data flows directly into CAD models, digital twins, or machine learning pipelines.

-

Safety and scalability: Designing safe motion envelopes and replicable modules ensures wider adoption across production lines.

Looking Ahead

As industries pursue smart manufacturing, 3D cameras will continue to expand in importance. They will not only enhance inspection and automation but also support research, healthcare, and cultural preservation. The revopoint 3d camera represents one example of how compact, versatile depth sensors are being brought into diverse professional contexts.

Organizations that invest early in 3D vision stand to improve quality, reduce costs, and future-proof operations in a digital world.

- Questions and Answers

- Opinion

- Motivational and Inspiring Story

- Technology

- Live and Let live

- Focus

- Geopolitics

- Military-Arms/Equipment

- Sicherheit

- Economy

- Beasts of Nations

- Machine Tools-The “Mother Industry”

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film/Movie

- Fitness

- Food

- Spiele

- Gardening

- Health

- Startseite

- Literature

- Music

- Networking

- Andere

- Party

- Religion

- Shopping

- Sports

- Theater

- Health and Wellness

- News

- Culture