How does the lack of indigenous machine tool production limit Africa’s ability to move beyond raw material exports?

How the Lack of Indigenous Machine Tool Production Limits Africa’s Ability to Move Beyond Raw Material Exports

For decades, Africa has been described as a continent rich in resources but poor in industrial development. From oil, gas, and copper to cocoa, coffee, and timber, Africa’s natural wealth is immense.

Yet, most of these resources leave the continent as raw materials rather than processed or manufactured goods. The result is a persistent cycle: Africa exports low-value raw commodities and imports high-value finished products.

A critical but often overlooked reason for this imbalance is the absence of indigenous machine tool production. Machine tools — the “mother industry” of industrialization — are essential for transforming raw resources into usable products.

Without them, Africa is locked into a subordinate position in the global economic chain.

These are how the lack of indigenous machine tool industries restricts Africa’s economic growth, hinders industrial diversification, and keeps the continent reliant on external powers.

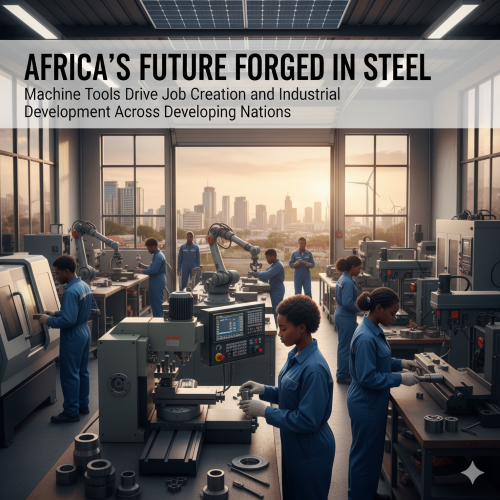

Machine Tools: The Missing Link in Africa’s Industrialization

Machine tools are devices such as lathes, milling machines, grinders, and CNC systems used to cut, shape, and refine raw materials into precise components. They are the backbone of every modern manufacturing process, from automotive assembly to aerospace, energy systems, agriculture machinery, and medical devices.

The absence of machine tool production in Africa means the continent largely imports both the machines needed for industrial activity and the spare parts to maintain them. This dependency has profound consequences.

1. Limits on Value Addition

The first and most obvious consequence is Africa’s difficulty in adding value to its raw materials.

-

Metals and Minerals: Africa is home to abundant iron ore, bauxite, cobalt, platinum, and copper reserves. But instead of processing these into steel products, machine components, or high-tech electronics, most are exported in raw form. Why? Because building the plants and equipment to process them requires machine tools that are mostly imported, expensive, and often out of reach.

-

Agriculture: Africa produces cocoa, coffee, cotton, and cashew nuts, but most of the chocolate, textiles, and processed products are made abroad. Without machine tools to manufacture processing equipment locally, African producers remain trapped at the lowest end of the agricultural value chain.

This inability to transform raw materials domestically means Africa earns only a fraction of the wealth generated from its resources. For example, Ghana and Côte d’Ivoire together supply more than 60% of the world’s cocoa, yet the multibillion-dollar global chocolate industry is dominated by Europe and the U.S.

2. Dependency on Foreign Machines and Spare Parts

A second consequence is technical dependence. Industries in Africa rely heavily on imported machines, from textile looms to oil drilling rigs. When these machines break down, spare parts often must be ordered from Europe, Asia, or America.

-

Delays: Waiting weeks or months for spare parts slows production and makes local industries unreliable.

-

Costs: Imported parts and machines are paid for in foreign currency, draining scarce reserves and increasing production costs.

-

Vulnerability: Political disputes, sanctions, or trade restrictions can disrupt supply, leaving factories idle.

Without indigenous machine tool production, African industries operate at the mercy of external suppliers, limiting competitiveness and growth.

3. Weak Domestic Manufacturing Ecosystem

The machine tool industry is not just about making machines — it anchors a broader manufacturing ecosystem. It fosters skills in precision engineering, metallurgy, design, and software integration.

Without this foundation, Africa struggles to develop other sectors such as:

-

Automotive and Aerospace: Countries like South Korea and China built global car and aircraft industries only after investing in domestic machine tool capabilities. Africa lacks this base, so its automotive production is mostly assembly of foreign parts rather than indigenous manufacturing.

-

Defense and Energy: Modern defense equipment, turbines, and renewable energy systems all require precision components that can only be produced with machine tools. Africa remains dependent on imports for these critical technologies.

-

Healthcare Manufacturing: Africa imports most medical equipment, from surgical instruments to MRI machines, because it lacks the precision engineering base that machine tools enable.

This absence perpetuates a shallow industrial base, where African industries consume imported technologies but rarely create them.

4. Stifled Innovation and Skills Development

Machine tools are not just products — they are platforms for innovation and learning. When engineers and machinists design, modify, and build tools, they develop technical expertise that spills over into other industries.

In Africa, the reliance on imported tools reduces opportunities for local engineers to experiment, adapt, or innovate. This creates a skills gap:

-

Vocational training often focuses on operating foreign machines, not designing or producing them.

-

Universities graduate engineers without exposure to toolmaking or precision manufacturing.

-

Local inventors struggle to prototype products because they lack access to advanced machining equipment.

The result is a generation of workers prepared for maintenance and assembly, not innovation and industrial leadership.

5. Loss of Economic Sovereignty

Perhaps the deepest impact of lacking indigenous machine tool industries is the erosion of economic sovereignty.

Countries that cannot build their own machines are perpetually dependent on those that can. This has strategic consequences:

-

Trade Deficits: Africa imports more in machinery and equipment than it earns from exporting manufactured goods, widening deficits.

-

Policy Dependence: Industrial strategy becomes shaped by what foreign suppliers allow, not what local economies need.

-

Geopolitical Vulnerability: If global supply chains are disrupted — as seen during the COVID-19 pandemic — Africa suffers disproportionately.

Without the mother industry, Africa’s ability to chart an independent path of development is curtailed.

What Could Indigenous Machine Tool Production Change?

If Africa developed its own machine tool industries, the transformation could be profound:

-

Raw Materials to Finished Goods: Instead of exporting crude oil, Africa could refine and produce petrochemicals, plastics, and synthetic materials. Instead of shipping iron ore, it could produce steel beams, cars, and machinery.

-

Job Creation: A machine tool sector would demand highly skilled engineers, machinists, and technicians, creating quality jobs and raising wages.

-

Technology Transfer: Domestic production would force mastery of advanced technologies such as CNC systems, robotics, and 3D printing.

-

Export Power: Africa could eventually export not only raw resources but also the machines to process them — moving up the global value chain.

The Way Forward

To overcome these limitations, Africa needs a strategic roadmap for machine tool development:

-

Regional Hubs: Not every country can develop a full-scale machine tool industry. But regional hubs (Nigeria, South Africa, Egypt, Ethiopia) could specialize in different areas and serve neighboring economies.

-

Public–Private Partnerships: Governments should work with universities, startups, and established industries to co-invest in toolmaking capacity.

-

Skills Development: Technical schools and universities must prioritize precision engineering, mechatronics, and tool design.

-

Resource Integration: Africa’s mineral wealth should be harnessed for local steel, aluminum, and component production instead of being exported raw.

-

Technology Leapfrogging: Instead of imitating outdated technologies, Africa could adopt modern CNC and digital manufacturing systems, positioning itself for the “Fourth Industrial Revolution.”

Conclusion

The lack of indigenous machine tool production is one of the silent barriers holding Africa back from industrial transformation. It limits value addition, sustains dependency, stifles skills and innovation, and erodes economic sovereignty.

As long as Africa remains a consumer of machine tools rather than a producer, it will remain trapped in the cycle of exporting raw materials and importing finished goods. Breaking this cycle requires a bold investment in the mother industry — one that can turn Africa’s abundant resources into engines of prosperity.

The question is not "whether Africa can afford to build a machine tool industry, but whether it can afford not to".

- Questions and Answers

- Opinion

- Motivational and Inspiring Story

- Technology

- Live and Let live

- Focus

- Geopolitics

- Military-Arms/Equipment

- Security

- Economy

- Beasts of Nations

- Machine Tools-The “Mother Industry”

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film/Movie

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Health and Wellness

- News

- Culture