What role should vocational training centers, polytechnics, and universities play in supporting a machine tool economy?

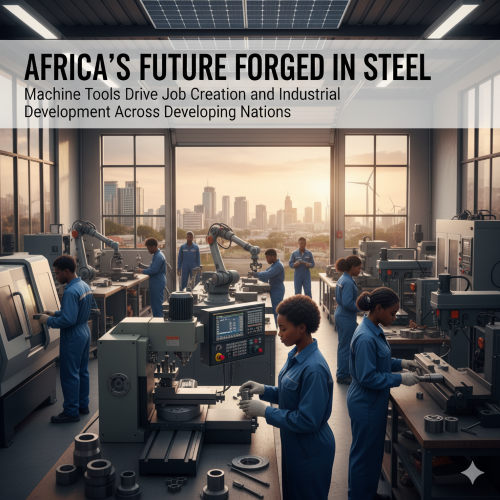

The Role of Vocational Training Centers, Polytechnics, and Universities in Supporting a Machine Tool Economy

Machine tools — lathes, milling machines, grinders, presses, and modern CNC systems — form the backbone of industrialization. They are rightly called the "mother machines," because they create the tools that build every other sector of the economy, from automotive to agriculture, energy to electronics.

For Africa and other developing regions, the creation of a sustainable machine tool industry could unlock industrial independence, reduce reliance on imports, and generate skilled employment. But such a transformation cannot occur without a solid human capital base.

Vocational training centers, polytechnics, and universities all have distinct, complementary roles to play in shaping the technical ecosystem that sustains a machine tool economy.

This article explores those roles in detail, and how collaboration between these institutions can provide Africa with the talent pipeline necessary to industrialize.

1. Why Human Capital Matters in a Machine Tool Economy

Machine tools are complex technologies that require engineers, machinists, technicians, and researchers at different levels of expertise. Unlike low-skill manufacturing, the machine tool sector demands precision, problem-solving, and adaptability. It is not enough to simply import machines; countries need local talent to design, manufacture, repair, and upgrade them.

-

Vocational centers produce practical operators and technicians who can run, maintain, and troubleshoot machines.

-

Polytechnics train middle-level technologists who bridge practical work and engineering design.

-

Universities focus on research, innovation, and advanced engineering to push machine tool development forward.

Without this layered ecosystem, Africa risks becoming dependent on foreign expertise even if it acquires the hardware.

2. The Role of Vocational Training Centers

Vocational training centers are the foundation of a machine tool economy because they provide the hands-on workforce for daily production activities.

Key Contributions

-

Basic Machining Skills: Training young people to operate lathes, milling machines, grinders, and welding equipment.

-

Maintenance & Repair: Ensuring that existing machine tools do not lie idle due to breakdowns. In many African factories, downtime is caused by lack of skilled technicians rather than lack of spare parts.

-

Entry-level Workforce: Preparing thousands of young people with employable skills within months or a year, unlike university programs that take longer.

-

Entrepreneurship Pathways: Graduates can start small machine shops to serve local communities, repairing agricultural tools, vehicle parts, and construction equipment.

Case Example

Germany’s dual education system, where apprentices split time between workshops and classrooms, demonstrates how vocational training can sustain a globally competitive manufacturing base. Africa can adapt this model, linking vocational centers directly to industrial clusters and machine tool workshops.

3. The Role of Polytechnics

Polytechnics occupy the middle ground between vocational centers and universities. They train technologists who combine practical skill with theoretical understanding — a crucial link in the machine tool chain.

Key Contributions

-

Design & Prototyping: Polytechnics can teach students to design and build prototypes of machine tools, especially using modern CAD/CAM and 3D printing.

-

Automation & CNC: As machine tools increasingly rely on digital control, polytechnics can focus on training students in CNC programming, robotics integration, and automation.

-

Applied Research: Unlike universities that often focus on theory, polytechnics can engage in applied problem-solving, such as adapting imported machines to African conditions (dust, humidity, unstable power supply).

-

Industrial Linkages: Polytechnics can establish machine tool incubation labs where students work on real industry projects, building a bridge between classroom and factory.

Example

India’s network of polytechnics has been instrumental in supplying the country’s small- and medium-scale industries with skilled technologists. A similar approach in Africa could enable domestic machine tool SMEs to flourish.

4. The Role of Universities

Universities must drive the innovation frontier of machine tools, ensuring Africa does not remain a follower but becomes a creator of advanced technology.

Key Contributions

-

Research & Development (R&D): Universities can develop indigenous machine tool designs, materials science innovations, and digital manufacturing solutions.

-

Faculty-Industry Partnerships: Engineering faculties can work with industries to solve specific technical challenges — for example, designing low-cost CNC machines suited for Africa’s small enterprises.

-

Knowledge Transfer: Universities can serve as hubs for patents, technical publications, and spin-off companies in precision engineering.

-

Training the Trainers: Universities supply the lecturers, researchers, and advanced engineers who will populate vocational centers and polytechnics.

-

Cross-disciplinary Innovation: Machine tools are no longer purely mechanical; they integrate electronics, software, and AI. Universities are best placed to train engineers who combine mechatronics, computer science, and materials engineering.

Example

China’s rapid rise in the machine tool industry was supported by heavy investment in technical universities. Institutions like Tsinghua University and Shanghai Jiao Tong University not only educated engineers but also became centers of industrial innovation.

5. Collaboration Between Institutions

For Africa to build a robust machine tool economy, these three institutions must work in synergy.

-

Vocational centers should supply operators and feed talented graduates into polytechnics.

-

Polytechnics should provide technologists who can design and improve machines, and channel advanced learners to universities.

-

Universities should conduct high-level research and feed innovations back into the vocational and polytechnic systems through curriculum updates and industrial partnerships.

This pipeline creates a continuous loop of knowledge and skill development, ensuring that machine tool industries have the necessary workforce at every level.

6. Policy and Industry Support

Governments and industries must also play enabling roles:

-

Curriculum Reform: Education systems should align with industrial needs, not just theory.

-

Industry Partnerships: Factories should offer internships, apprenticeships, and research collaborations.

-

Investment in Equipment: Training institutions need up-to-date machines, including modern CNCs, not outdated equipment from the 1970s.

-

Regional Centers of Excellence: Africa can pool resources by creating continental hubs for machine tool education and R&D, reducing duplication and maximizing scale.

No machine tool economy can survive without skilled people. Machines may be imported, but without trained operators, technologists, and engineers, they quickly become obsolete or underutilized. Vocational training centers, polytechnics, and universities must therefore be seen not as isolated silos, but as interconnected pillars of Africa’s industrial future.

By cultivating a layered ecosystem of skills — from the hands-on machinist to the research-driven engineer — African nations can lay the foundation for true industrial sovereignty. The machine tool industry will not only build machines but also build people: a generation of young Africans equipped to shape their continent’s destiny.

- Questions and Answers

- Opinion

- Motivational and Inspiring Story

- Technology

- Live and Let live

- Focus

- Geopolitics

- Military-Arms/Equipment

- Ασφάλεια

- Economy

- Beasts of Nations

- Machine Tools-The “Mother Industry”

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film/Movie

- Fitness

- Food

- Παιχνίδια

- Gardening

- Health

- Κεντρική Σελίδα

- Literature

- Music

- Networking

- άλλο

- Party

- Religion

- Shopping

- Sports

- Theater

- Health and Wellness

- News

- Culture