How does machine tool investment tie into Africa’s push for food security (e.g., making farm machinery locally)?

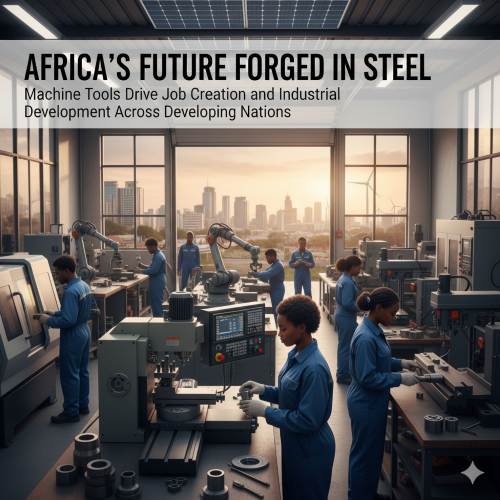

Machine Tools and Food Security: Building Africa’s Farm Machinery Locally-

Food security remains one of Africa’s most pressing challenges. Despite possessing 60% of the world’s uncultivated arable land, the continent continues to rely heavily on food imports, spending more than $40 billion annually to feed its growing population. At the same time, millions of smallholder farmers struggle with outdated tools, low productivity, and limited access to modern equipment.

If Africa is to achieve true food sovereignty, it must modernize agriculture—not just by importing tractors, harvesters, and irrigation systems, but by building the capacity to manufacture farm machinery locally. At the heart of this transformation lies the machine tool industry, the “mother of all industries.” Machine tools are the foundation for producing the plows, planters, milling machines, spare parts, and tractors needed to mechanize African agriculture. Without machine tool investment, Africa will remain dependent on imported agricultural machinery, undermining both food security and economic sovereignty.

Why Machine Tools Matter for Agriculture

Machine tools are devices that shape, cut, and mold metals and other materials into components. They are the backbone of industrialization: every tractor engine, irrigation pump, or combine harvester begins as raw material processed through a machine tool.

For agriculture, machine tools are essential in several ways:

-

Tractors and Implements: Machine tools manufacture the engines, chassis, and attachments (plows, harrows, planters, seed drills) that boost farm productivity.

-

Irrigation Equipment: Pipes, pumps, and valves are produced using precision tools, making large-scale irrigation possible.

-

Food Processing Machines: Milling machines, oil presses, grain threshers, and dryers all depend on machine tools.

-

Maintenance and Spare Parts: Even imported farm equipment eventually needs parts. A strong local machine tool sector ensures repairs and replacements, reducing downtime.

Without domestic machine tool industries, Africa must continuously import both farm machinery and spare parts—draining foreign exchange and keeping costs high for farmers.

The Link Between Machine Tools and Food Security

Food security is about more than food availability; it is also about affordability, access, and resilience. Machine tool investment directly supports these dimensions:

1. Boosting Agricultural Productivity

Most African farmers still rely on hand tools like hoes and cutlasses. Mechanization rates remain the lowest in the world, with fewer than 20 tractors per 10,000 hectares compared to 200–400 in Asia and Latin America. Locally produced farm machinery could lower costs and make mechanization accessible to millions of smallholders.

2. Reducing Import Dependence

Currently, African countries import most of their tractors and implements from the United States, Europe, China, and India. These machines are often designed for large-scale industrial farming, ill-suited to small African farms, and expensive to maintain. By manufacturing farm machinery locally, African nations could tailor designs to local needs, while saving billions in foreign exchange.

3. Building Rural Resilience

Imported machines break down frequently, and spare parts may take months to arrive. A domestic machine tool sector ensures quick repairs and affordable spare parts, reducing downtime during critical planting and harvesting seasons.

4. Creating Jobs Along the Value Chain

Machine tool industries support not only the production of tractors but also related industries like steel, automotive parts, and precision engineering. This creates jobs for engineers, technicians, and factory workers, while boosting rural economies through affordable farm equipment.

5. Empowering Smallholder Farmers

Local machine tool industries can design scaled-down machinery appropriate for Africa’s small farms—two-wheel tractors, animal-drawn implements, solar-powered irrigation pumps—making modern tools accessible to those who cannot afford large imported machines.

Practical Applications: Machine Tools in Agricultural Development

Tractors and Implements

A single tractor requires hundreds of precision-machined components—gearboxes, pistons, crankshafts, and axles. Without machine tools, these must be imported at high cost. By investing in machine tool workshops, African states can produce basic tractors domestically, gradually upgrading toward higher technology.

Irrigation and Water Management

Drought and erratic rainfall threaten African food security. Locally made irrigation pumps, sprinkler systems, and water pipelines—produced with machine tools—can provide farmers with stable water access. Machine tool industries can also support solar-powered pumps, aligning with renewable energy efforts.

Agro-Processing Machines

Food security isn’t just about growing crops; it’s also about processing them into edible and storable forms. Machine tools enable the production of:

-

Rice milling machines, reducing post-harvest losses.

-

Cassava graters and dryers, key for West African diets.

-

Oilseed presses, supporting cooking oil self-sufficiency.

-

Grain threshers and silos, cutting waste during storage.

Maintenance Ecosystems

Africa has graveyards of broken tractors and harvesters donated or imported from abroad. A domestic machine tool industry could revive many of these through local spare parts production, maximizing utility and reducing waste.

Case Studies and Lessons

-

India’s Green Revolution: India’s rise in food self-sufficiency was supported not just by new seeds and fertilizers, but by the growth of its domestic machine tool and agricultural equipment industries. Companies like Mahindra & Mahindra now produce millions of affordable tractors annually.

-

Brazil’s Agricultural Boom: Brazil invested in local farm machinery production in the 1970s, allowing small and medium farmers to access affordable tools. Today, it is a global food exporter.

-

Nigeria’s Challenges: Nigeria has imported thousands of tractors, but many lie idle due to lack of spare parts. This highlights the need for domestic machine tool and parts industries.

Financing and Policy for Agricultural Machine Tools

To tie machine tool investment to food security, African governments must adopt supportive policies:

-

Subsidies and Incentives: Offer tax breaks to local firms producing farm machinery.

-

Public Procurement: Governments should buy domestically produced tractors and irrigation systems for distribution through farmer cooperatives.

-

Financing Models: Use development banks, sovereign wealth funds, and public-private partnerships to finance machine tool industries focused on agriculture.

-

Regional Collaboration: Through the African Continental Free Trade Area (AfCFTA), countries could specialize—Ethiopia in tractors, Kenya in irrigation, Nigeria in agro-processing machines—building a continental ecosystem.

-

Skills Development: Link vocational training centers and polytechnics with machine tool factories, training young engineers in agricultural machinery design and maintenance.

Challenges and Solutions

-

High Start-Up Costs: Building machine tool factories requires heavy investment. Solution: blended financing from sovereign wealth funds, AfDB, and PPPs.

-

Technology Gaps: Africa lags behind in CNC, robotics, and precision engineering. Solution: strategic partnerships with BRICS nations for technology transfer.

-

Policy Instability: Shifting agricultural and industrial policies discourage long-term investment. Solution: continental-level policy frameworks under AU and AfCFTA.

Machine tool investment is not an abstract industrial policy—it is directly tied to Africa’s food security. Without domestic capacity to produce tractors, irrigation pumps, and processing machines, Africa will remain vulnerable to global supply shocks and dependent on expensive imports.

By investing in machine tools, Africa can:

-

Produce affordable, locally adapted farm machinery.

-

Reduce reliance on imports and save foreign exchange.

-

Empower smallholder farmers to increase productivity.

-

Build resilience through local spare parts industries.

-

Create jobs and skills that spill over into other industries.

In short, food sovereignty in Africa cannot be separated from industrial sovereignty. Machine tool investment is the missing link that can connect Africa’s vast agricultural potential to its dream of feeding itself and the world.

- Questions and Answers

- Opinion

- Motivational and Inspiring Story

- Technology

- Live and Let live

- Focus

- Geopolitics

- Military-Arms/Equipment

- Security

- Economy

- Beasts of Nations

- Machine Tools-The “Mother Industry”

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film/Movie

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Health and Wellness

- News

- Culture