Could international partnerships for training (with India, Germany, or China) accelerate Africa’s machine tool skills base?

Could International Partnerships for Training (with India, Germany, or China) Accelerate Africa’s Machine Tool Skills Base?

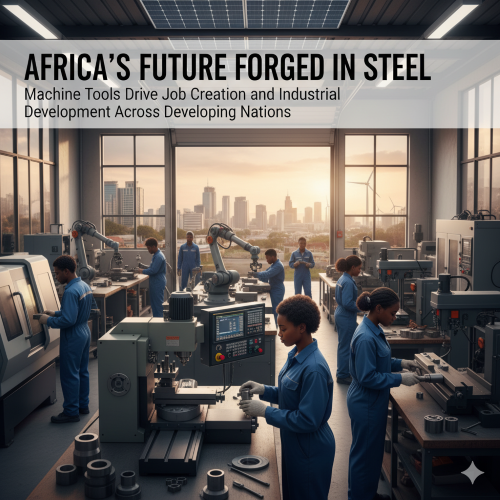

Industrialization in the 21st century will be shaped by those nations that master the machine tool industry—the backbone of all manufacturing. Machine tools enable the production of other machines, from tractors and medical equipment to automobiles and defense hardware.

Africa, however, has long remained at the periphery of this sector, relying heavily on imports of precision machinery while struggling to develop the domestic skills base necessary to build a sustainable machine tool economy.

One pathway forward is international partnerships for training, particularly with countries that have successfully built robust machine tool industries such as India, Germany, and China.

These nations represent different development models but share one commonality: they invested heavily in skill-building to underpin their machine tool industries. For Africa, partnerships with such countries could accelerate the development of local machinists, engineers, and technicians—provided the collaborations are structured around genuine capacity-building rather than dependency.

This article explores how international training partnerships could benefit Africa, the potential risks, and the specific strategies that could transform Africa’s skills base in the machine tool sector.

1. Why Africa Needs International Training Partnerships

a) Skills Gap in Technical Education

African universities, polytechnics, and vocational centers often emphasize theoretical instruction while neglecting practical, hands-on training in machining and tool-making. Graduates may understand design principles but lack the ability to operate CNC (Computer Numerical Control) machines or precision grinders. Partnerships with global leaders could bridge this gap.

b) Accelerating the Learning Curve

It took countries like Germany centuries and China several decades to build their machine tool expertise. Africa does not have the luxury of time. Collaborations can help Africa leapfrog stages of development by accessing pre-existing knowledge, technical manuals, and training methodologies.

c) Exposure to Advanced Technologies

Machine tools today are not limited to manual lathes and drills. They are increasingly AI-driven, robotics-assisted, and digitally integrated. International training programs can expose African engineers to these emerging fields, ensuring that the continent does not get locked into outdated technologies.

2. What Africa Can Learn from India, Germany, and China

Germany: Precision and Vocational Excellence

-

Germany is the world’s leading exporter of high-end machine tools. Its dual vocational training system (a combination of classroom instruction and apprenticeship in industry) ensures a steady supply of highly skilled machinists.

-

African countries could replicate this by partnering with German vocational schools and companies such as Siemens or DMG Mori to train African youth in advanced machining and tool design.

India: Affordable Engineering and Scalable Training

-

India’s machine tool sector grew rapidly after independence, with government institutions like the Central Manufacturing Technology Institute (CMTI) and public-private collaborations nurturing thousands of engineers.

-

India’s advantage lies in low-cost but high-quality technical training and adaptability to resource-constrained environments. African nations could adopt India’s scalable training models and collaborate through platforms like the India-Africa Forum Summit.

China: Mass Training and Technology Transfer

-

China transformed itself from a machine tool importer to one of the world’s largest producers within three decades. It did this by sending students abroad, bringing foreign experts in, and establishing specialized training centers attached to industrial zones.

-

African countries can learn from China’s method of pairing training programs with local production hubs, ensuring that skills are immediately applied to industry rather than remaining theoretical.

3. Forms of International Training Partnerships

a) Exchange Programs and Scholarships

-

African governments can negotiate scholarships for students to study mechanical engineering and tool-making in partner countries.

-

Such students should be tied to “return and serve” clauses that require them to work in Africa for a fixed number of years after training.

b) Joint Training Institutes

-

India, Germany, or China could collaborate with African governments to set up Machine Tool Training Institutes. These centers would be equipped with modern CNC machines, simulation software, and tool-testing labs.

-

Examples already exist, such as the Indo-German Tool Room (IGTR) model, which could be replicated in African countries.

c) Industry Partnerships

-

Instead of relying only on governments, African machine tool projects can directly partner with private companies (e.g., Bosch, Bharat Forge, or Haier).

-

These companies could run in-house apprenticeship programs for African trainees, blending classroom learning with real-world production.

d) Train-the-Trainer Programs

-

A sustainable approach is to first train African instructors, who can then return and multiply knowledge across multiple institutions.

-

Germany’s GIZ and India’s ITEC programs already support such models, which Africa could expand.

4. Benefits of International Training Partnerships

-

Skill Acceleration: African machinists and engineers could gain in a decade what took others several decades.

-

Industrial Linkages: Training partnerships could be tied to actual production contracts, ensuring skills are not wasted.

-

Technology Transfer: Beyond people, training programs can expose Africa to new technologies, CAD/CAM systems, and maintenance know-how.

-

Cultural Exchange: Collaboration fosters professional networks, allowing African engineers to tap into global communities of practice.

5. Risks and Challenges

-

Dependency Risk: If partnerships are not structured carefully, Africa may remain dependent on foreign trainers instead of building self-sufficiency.

-

Brain Drain: Skilled trainees might emigrate instead of returning to Africa, especially if local conditions remain unattractive.

-

Unequal Agreements: Partnerships with external powers sometimes come with conditions that prioritize their own markets over African development.

-

Mismatch with Local Needs: Training must be adapted to African industrial contexts; importing irrelevant models will waste resources.

6. Strategies for Maximizing the Impact

a) Align Training with Local Industry Needs

If Africa plans to develop agricultural machinery, training should emphasize CNC parts for tractors, plows, and irrigation systems. For healthcare, it could focus on precision medical devices.

b) Integrate Training with AfCFTA Industrial Goals

Instead of duplicating efforts in each country, regional centers of excellence could serve multiple African nations under the African Continental Free Trade Area.

c) Build Retention Mechanisms

-

Competitive salaries, housing allowances, and career progression pathways for returning engineers.

-

Bonded contracts to ensure beneficiaries of international training serve in local industries for a set period.

d) Use Diaspora as a Bridge

African engineers already working in Germany, India, or China could serve as liaisons, helping design training curricula and mentoring younger machinists.

e) Negotiate Fair Technology Partnerships

Training should be tied to joint R&D, co-production, and local assembly projects, not just classroom instruction.

7. A Strategic Imperative

International partnerships for training could be a game-changer for Africa’s machine tool sector. Germany offers precision and vocational rigor, India provides scalable and cost-effective models, while China demonstrates how rapid industrial capacity can be built through massive training programs. However, partnerships alone are not enough. Africa must ensure that training programs are locally relevant, industry-linked, and future-oriented.

If structured well, such collaborations could create a new generation of African machinists and engineers who are not only skilled but also committed to building industries at home. By combining external expertise with internal vision, Africa can accelerate its machine tool revolution and lay the foundation for a resilient, self-reliant industrial economy.

- Questions and Answers

- Opinion

- Motivational and Inspiring Story

- Technology

- Live and Let live

- Focus

- Geopolitics

- Military-Arms/Equipment

- Security

- Economy

- Beasts of Nations

- Machine Tools-The “Mother Industry”

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film/Movie

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Health and Wellness

- News

- Culture