Thermoforming Mould

Custom Thermoforming Moulds for Packaging, Automotive, and Medical Applications: Trends and Case Studies

In modern manufacturing, Thermoforming Mould technology has emerged as a powerful and adaptable process that bridges innovation, functionality, and cost-effectiveness. From food packaging to automotive interior components and precise medical equipment, custom thermoforming moulds have become essential tools in shaping the future of various industries.

This article explores the evolution, trends, and real-world case studies of custom thermoforming moulds, offering deep insights into their applications across packaging, automotive, and medical sectors. It also covers material selection, design innovations, sustainability efforts, and what the future holds for this ever-evolving technology.

Understanding Thermoforming Mould Technology

Thermoforming moulding is a manufacturing process where a plastic sheet is heated until it becomes pliable, then formed over a mould to take its shape. Once cooled, it hardens into the desired structure. The mould—crafted from materials like aluminum, composite, or epoxy—is the heart of this process, determining the precision, finish, and performance of the final product.

A Thermoforming Mould is not just a shaping tool; it’s an engineering innovation that ensures quality, durability, and design fidelity. The accuracy of the mould directly affects product consistency, aesthetics, and performance, especially in high-demand industries like automotive and medical devices.

Types of Thermoforming Moulds

-

Male Moulds (Positive Moulds)

These moulds create parts with an interior cavity. The plastic sheet drapes over the mould, making it ideal for applications needing smooth internal surfaces, such as packaging trays or automotive dashboards. -

Female Moulds (Negative Moulds)

The plastic sheet is drawn into the mould cavity, creating parts with detailed outer surfaces. This type is widely used in medical devices and components requiring tight dimensional tolerances. -

Matched Moulds

Both male and female moulds are used together for high precision, typically in advanced applications such as aerospace panels or complex medical housings.

Material Considerations for Custom Thermoforming Moulds

Selecting the right mould material depends on production volume, detail requirements, and temperature exposure. Common choices include:

-

Aluminum: Offers durability, fine detail, and excellent heat transfer, ideal for high-volume production.

-

Epoxy and Composite Moulds: Cost-effective for prototyping or small runs, offering flexibility in design changes.

-

Steel: Used for long-term, high-precision moulds where wear resistance is critical.

The right material choice enhances mould life, ensures product accuracy, and reduces long-term production costs.

Applications Across Key Industries

1. Packaging Industry

The packaging industry has embraced Thermoforming Mould technology for its speed, precision, and flexibility. Whether for food, electronics, or consumer goods, thermoformed packaging offers protection, visual appeal, and sustainability.

Trends in Packaging Thermoforming Moulds:

-

Lightweight Materials: Reduction of plastic weight without sacrificing strength or rigidity.

-

Recyclable Polymers: Growing preference for PET, rPET, and biodegradable plastics.

-

Digital Mould Design: CAD/CAM and 3D scanning allow rapid customization and shorter development cycles.

Case Study – Food Packaging Efficiency:

A European food packaging company adopted custom thermoforming moulds to produce multi-compartment meal trays. By optimizing mould cooling channels and airflow, they achieved a 30% reduction in cycle time and 20% material savings, demonstrating how precise mould engineering directly impacts productivity and sustainability.

2. Automotive Industry

The automotive sector relies heavily on Thermoforming Mould systems for producing interior and exterior components. These include dashboard panels, door trims, seat backs, and underbody shields.

Trends in Automotive Thermoforming Moulds:

-

Integration of Lightweight Composites: To meet fuel efficiency goals.

-

Aesthetic Customization: Enhanced surface textures and finishes mimicking leather or carbon fiber.

-

Hybrid Moulding Techniques: Combining thermoforming with injection moulding for complex geometries.

Case Study – Lightweight Door Panels:

An automotive manufacturer collaborated with a thermoforming specialist to develop a mould for high-impact ABS panels. The resulting design reduced part weight by 18%, improved sound insulation, and cut assembly costs. The custom Thermoforming Mould was engineered for precision and repeatability, leading to scalable production across multiple vehicle models.

3. Medical Applications

In the medical field, precision and cleanliness are paramount. Custom Thermoforming Moulds are used to produce device housings, surgical trays, orthotic supports, and disposable packaging.

Trends in Medical Thermoforming Moulds:

-

Cleanroom Manufacturing: Ensures sterile conditions and compliance with ISO standards.

-

Antimicrobial Materials: Integration of additives into plastics to prevent bacterial growth.

-

Rapid Prototyping: Accelerated mould production to support R&D and testing of new devices.

Case Study – Surgical Instrument Packaging:

A medical device manufacturer used aluminum thermoforming moulds to develop sterile packaging for surgical tools. The mould design allowed for ultra-smooth contours and consistent sealing surfaces, improving sterilization efficiency and reducing contamination risks. The new mould system helped the company achieve a 40% faster time-to-market for its updated product line.

Design Innovations in Custom Thermoforming Moulds

1. 3D Simulation and Virtual Testing

Advanced CAD software enables manufacturers to simulate material flow, heat distribution, and forming behavior before physical mould creation. This minimizes errors and reduces development time.

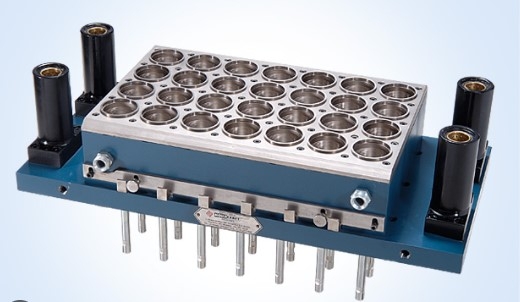

2. Multi-Cavity Moulds

Modern moulds are designed to produce multiple parts simultaneously, maximizing output and reducing per-unit costs.

3. Enhanced Cooling Systems

Optimized cooling channels improve cycle times and part consistency. Uniform cooling ensures dimensional accuracy and reduces warping.

4. Surface Texturing and Finishing

From matte finishes to high-gloss effects, texturing adds visual appeal and tactile quality. Laser etching and CNC milling make this possible with remarkable precision.

Sustainability and Energy Efficiency

Sustainability has become a defining trend across all industries using Thermoforming Mould technology. Key strategies include:

-

Use of Recycled Materials: rPET and bio-based plastics are now common in moulded packaging.

-

Energy-Efficient Heating Systems: Infrared and zoned heaters minimize waste heat.

-

Lifecycle Optimization: Designing moulds for reusability and extended service life reduces environmental impact.

Manufacturers are also leveraging data analytics and IoT to monitor mould performance, anticipate maintenance needs, and prevent costly downtime.

and Solutions in Thermoforming Mould Design

-

Material Shrinkage:

-

Challenge: Plastics shrink differently based on material type.

-

Solution: Precise thermal modeling and compensation during CAD design.

-

Uniform Wall Thickness:

-

Challenge: Uneven stretching can lead to weak spots.

-

Solution: Controlled vacuum pressure and pre-stretching techniques.

-

Surface Defects:

-

Challenge: Imperfect finishes due to poor venting or uneven temperature.

-

Solution: High-quality mould polishing and optimized vent placements.

Future Outlook: Smart and Digital Moulding

The future of Thermoforming Mould technology lies in smart manufacturing and digital integration. Real-time monitoring, AI-based defect detection, and predictive maintenance will redefine production efficiency.

-

AI-Powered Design Optimization: Machine learning can recommend ideal mould geometries based on past performance data.

-

3D Printed Mould Inserts: Rapid tooling and prototyping with metal or polymer additive manufacturing.

-

Closed-Loop Systems: Real-time feedback ensures consistent part quality and reduces waste.

These advancements promise not only faster turnaround but also higher precision and sustainability across all manufacturing sectors.

Conclusion

The role of custom Thermoforming Moulds extends far beyond shaping plastic; it’s about driving innovation, efficiency, and quality across industries. From packaging solutions that balance aesthetics and sustainability, to automotive parts that enhance performance and safety, and medical devices that ensure precision and hygiene—thermoforming moulds are the silent force behind modern manufacturing excellence.

As digital tools, eco-conscious materials, and intelligent design converge, Thermoforming Mould technology will continue to evolve—paving the way for smarter, cleaner, and more efficient production systems across the globe.

- Questions and Answers

- Opinion

- Motivational and Inspiring Story

- Technology

- Live and Let live

- Focus

- Geopolitics

- Military-Arms/Equipment

- Безопасность

- Economy

- Beasts of Nations

- Machine Tools-The “Mother Industry”

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film/Movie

- Fitness

- Food

- Игры

- Gardening

- Health

- Главная

- Literature

- Music

- Networking

- Другое

- Party

- Religion

- Shopping

- Sports

- Theater

- Health and Wellness

- News

- Culture