Aluminium Z Channel: Custom Extrusion Solutions with Certified Material Performance

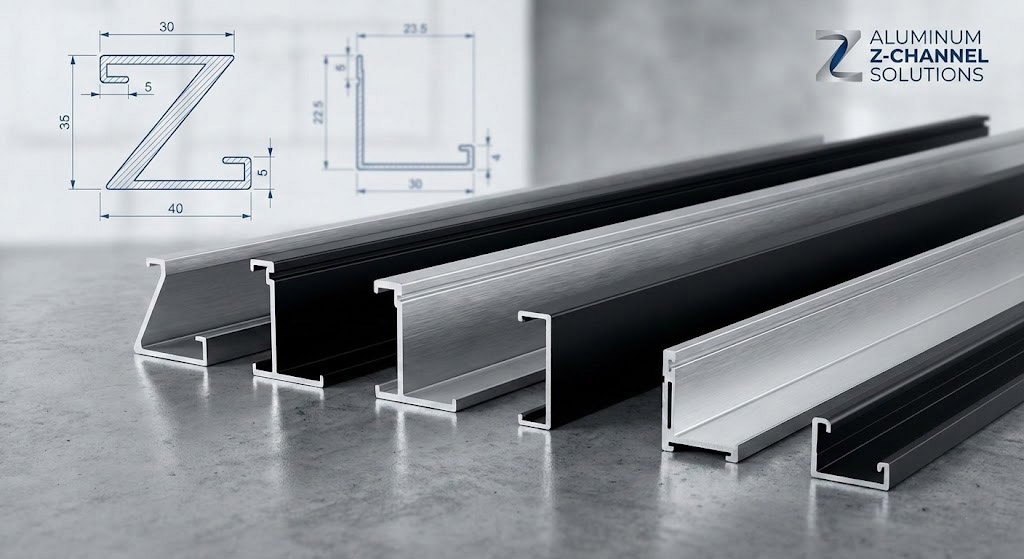

What Is an Aluminium Z Channel?

An aluminium Z channel is a lightweight structural extrusion featuring a distinctive Z-shaped cross-section. This versatile profile combines excellent strength-to-weight ratio with superior corrosion resistance, making it an essential component in construction, manufacturing, and industrial applications. The Z-configuration provides exceptional load distribution capabilities and flexible mounting options for framing systems, support structures, edge trim, and architectural installations.

Why Choose Our Aluminium Z Channel Manufacturing?

1. Custom Die Manufacturing from Technical Drawings

Transform your design concepts into precision-manufactured reality. Our engineering team specializes in custom die development based on your technical drawings and specifications. Whether you require standard Z channel dimensions or complex custom profiles, we provide complete tooling solutions that deliver consistent accuracy across production runs.

Custom tooling advantages:

- Precise dimensional control matching your specifications

- Design flexibility for unique geometric requirements

- Competitive tooling costs with fast amortisation

- Quick turnaround from drawing approval to first article

- Engineering support for design optimisation

2. Complete Range of Aluminium Alloys with Certified Performance Data

Material selection is critical to product performance. We manufacture aluminium Z channels in multiple alloy grades, each optimised for specific applications. Every alloy comes with complete chemical composition analysis and mechanical property certification.

Alloy Options and Performance Characteristics

6063-T5/T6 – Architectural Grade

- Chemical Composition: Si 0.20-0.6%, Mg 0.45-0.9%, Fe ≤0.35%, Cu ≤0.10%

- Mechanical Properties (T6):

- Tensile Strength: 205-245 MPa

- Yield Strength: 170-195 MPa

- Elongation: ≥8%

- Hardness: 60-75 HB

- Applications: Window frames, curtain walls, architectural trim, decorative profiles

- Key Benefits: Excellent extrudability, superior surface finish, optimal for anodizing

6061-T6 – Structural Grade

- Chemical Composition: Mg 0.8-1.2%, Si 0.4-0.8%, Cu 0.15-0.4%, Cr 0.04-0.35%

- Mechanical Properties:

- Tensile Strength: 290-310 MPa

- Yield Strength: 240-275 MPa

- Elongation: ≥10%

- Hardness: 90-95 HB

- Applications: Structural frames, load-bearing components, machine parts, transport equipment

- Key Benefits: High strength-to-weight ratio, excellent machinability, good weldability

6060-T6 – European Standard

- Chemical Composition: Si 0.30-0.6%, Mg 0.35-0.6%, Fe 0.10-0.30%

- Mechanical Properties:

- Tensile Strength: 190-210 MPa

- Yield Strength: 150-170 MPa

- Elongation: ≥8%

- Hardness: 55-70 HB

- Applications: Architectural systems, light structural components, European market requirements

- Key Benefits: Similar to 6063 with enhanced formability, cost-effective production

6082-T6 – High-Strength Structural

- Chemical Composition: Si 0.7-1.3%, Mg 0.6-1.2%, Mn 0.4-1.0%

- Mechanical Properties:

- Tensile Strength: 310-340 MPa

- Yield Strength: 260-290 MPa

- Elongation: ≥10%

- Hardness: 95-105 HB

- Applications: Heavy-duty structural applications, transportation, industrial equipment, bridge components

- Key Benefits: Superior strength comparable to steel, excellent fatigue resistance, best choice when maximum strength is required

All materials supplied with:

- Mill test certificates (EN 10204 3.1 or equivalent)

- Chemical composition analysis

- Mechanical property test results

- Traceability documentation

3. Comprehensive Surface Treatment Options

Protect and enhance your aluminium Z channels with our complete range of surface finishing services. All treatments are performed in-house with customizable specifications.

Mill Finish (Raw Aluminium)

- Natural aluminium appearance with light oxide layer

- Suitable for secondary coating or non-corrosive environments

- Most economical option for protected applications

Anodizing – Customizable Film Thickness

- Standard Class: 10-15 microns for indoor architectural applications

- Enhanced Class: 15-20 microns for outdoor architectural use

- Heavy-Duty Class: 20-25 microns for marine and industrial environments

- Available colors: Clear (natural), bronze, black, champagne, custom colors

- Standards compliance: AAMA 611, Qualanod, MIL-A-8625

Powder Coating – Premium Brand Options

- Your choice of powder brands: AkzoNobel, Tiger Drylac, PPG, Jotun, or client-specified

- Color matching: RAL, Pantone, or custom color development

- Finish options: Gloss, matte, textured, metallic

- Film thickness: 60-100 microns based on application requirements

- Durability ratings: AAMA 2603, 2604, 2605 certifications available

Surface treatment selection guidance available based on environmental exposure, aesthetic requirements, and performance expectations.

4. Complete Fabrication Services in Our Advanced Machining Facility

Raw extrusions represent only the foundation. Our state-of-the-art fabrication center transforms standard profiles into finished, installation-ready components.

Available secondary operations:

- Precision cutting: CNC sawing to ±0.5mm tolerance, lengths up to 7 meters

- Drilling and tapping: CNC machining for mounting holes, threaded inserts, complex hole patterns

- Milling operations: Slots, notches, pockets, chamfers, and custom geometries

- Bending and forming: Press brake forming, roll bending for curved applications

- Punching and stamping: High-volume hole punching, embossing, coining

- Deburring and finishing: Tumbling, brushing, polishing for smooth edges

- Assembly services: Riveting, mechanical fastening, component assembly

This vertical integration reduces your supply chain complexity while ensuring quality consistency from extrusion through finished fabrication.

5. Uncompromising Quality Control: From Aluminium Ingot to Finished Product

Quality starts at the source. Our vertically integrated production model provides complete control over material quality and consistency.

Our quality assurance process:

Stage 1: Raw Material Control

- Direct procurement of 99.7% pure aluminium ingots from certified smelters

- Incoming inspection and chemical analysis verification

- Traceability systems tracking each ingot batch

Stage 2: In-House Billet Casting

- Proprietary casting process ensuring uniform alloy distribution

- Controlled cooling and homogenization heat treatment

- Ultrasonic testing for internal soundness

- Unlike competitors who purchase pre-cast billets, we control metallurgy from the start

Stage 3: Extrusion Production

- Temperature-controlled extrusion process for consistent mechanical properties

- In-line dimensional monitoring and correction

- Real-time process documentation

Stage 4: Heat Treatment and Aging

- Precision solution heat treatment and artificial aging

- Hardness testing to verify temper achievement

- Mechanical property sampling and tensile testing

Stage 5: Surface Treatment Quality

- Anodizing film thickness measurement (eddy current testing)

- Powder coating thickness verification

- Adhesion and durability testing per industry standards

Stage 6: Final Inspection

- Dimensional verification against specifications

- Visual inspection for surface quality

- Packaging inspection to prevent transit damage

Quality certifications:

- ISO 9001:2015 Quality Management System

- Material certificates provided with every shipment

- Third-party testing available upon request

This comprehensive quality control approach eliminates variables introduced by third-party material suppliers, ensuring every aluminium Z channel meets or exceeds your specifications.

Common Applications for Aluminium Z Channel

Our aluminium Z channels serve diverse industries across architectural and industrial sectors:

Architectural & Construction:

- Curtain wall framing systems and mullions

- Window and door frame components

- Ceiling suspension systems

- Facade cladding support structures

- Interior partition framing

Industrial & Manufacturing:

- Equipment frames and support brackets

- Conveyor system components

- Machine guarding and safety barriers

- Mounting channels for electrical/mechanical systems

- Enclosure frames and chassis

Transportation:

- Commercial vehicle body structures

- Trailer and container framing

- Rail car interior components

- Automotive trim and structural parts

Renewable Energy:

- Solar panel mounting rails and frames

- Photovoltaic support structures

- Energy storage system enclosures

Marine & Outdoor:

- Boat structures and deck components (6082-T6 recommended)

- Dock and marina installations

- Outdoor furniture frames

Technical Support: Alloy Selection Guidance

Not sure which alloy is right for your application? Our engineering team helps you select the optimal material based on:

- Load requirements: Static and dynamic stress analysis

- Environmental exposure: Corrosion resistance needs

- Fabrication requirements: Welding, forming, or machining considerations

- Budget constraints: Balancing performance with cost-effectiveness

- Compliance standards: Meeting industry-specific material requirements

Request Your Custom Aluminium Z Channel Quote

Ready to discuss your aluminium Z channel requirements? Our technical sales team provides comprehensive support from initial design through production.

Start your project today:

📋 Submit Technical Drawings – Email your CAD files or sketches for custom die quotation

🔬 Specify Material Requirements – Select alloy grade based on our composition and strength tables

🎨 Choose Surface Treatment – Specify anodizing thickness or powder coating brand preference

🔧 Define Fabrication Needs – List cutting, drilling, or other secondary operations required

📊 Receive Detailed Quotation – Transparent pricing with lead times and MOQ information

Contact Syntech Metals team to transform your specifications into precision-manufactured aluminium Z channels backed by complete material certification and quality documentation.

- Questions and Answers

- Opinion

- Motivational and Inspiring Story

- Technology

- Live and Let live

- Focus

- Geopolitics

- Military-Arms/Equipment

- Security

- Economy

- Beasts of Nations

- Machine Tools-The “Mother Industry”

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film/Movie

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Health and Wellness

- News

- Culture