Exploring the Versatility and Applications of PP Sheets

Polypropylene (PP) sheets are versatile and widely used materials in various industries due to their unique properties and cost-effectiveness. These sheets are made from polypropylene, a thermoplastic polymer known for its strength, chemical resistance, and versatility. In this blog, we will delve into what P p sheet Price in India are, their manufacturing process, benefits, and applications across different sectors.

What are PP Sheets?

PP sheets are flat, thin layers of polypropylene that come in various thicknesses and sizes. They are produced through an extrusion process, which involves melting polypropylene pellets and shaping them into sheets. The resulting material is lightweight, durable, and Pp sheet price in kolkata to many chemicals, making it suitable for a wide range of applications.

Manufacturing Process of PP Sheets

The production of PP sheets involves several key steps:

-

Raw Material Preparation: Polypropylene pellets, the raw material, are first fed into an extruder. The quality of these pellets is crucial for producing high-quality sheets.

-

Extrusion: The pellets are melted at high temperatures within the extruder. The molten polymer is then forced through a flat die, forming a continuous sheet.

-

Calendering: The extruded sheet passes through a series of rollers, known as calenders, which smooth and flatten the material to the desired thickness. This process also helps to improve the sheet's surface finish.

-

Cooling: After calendering, the sheet is cooled to solidify its structure. This is typically done using air or water cooling systems.

-

Cutting and Finishing: The cooled sheet is then cut into the required sizes and may undergo additional finishing processes, such as surface treatment or printing, depending on the intended application.

Benefits of PP Sheets

-

Durability: PP sheets are highly durable and resistant to impact, making them ideal for applications that require tough, long-lasting materials.

-

Chemical Resistance: Polypropylene is resistant to many chemicals, including acids, bases, and solvents. This makes PP sheets suitable for use in environments where chemical exposure is common.

-

Lightweight: Despite their strength, PP sheets are lightweight, which makes them easy to handle and reduces transportation costs.

-

Moisture Resistance: PP sheets are highly resistant to moisture, preventing water absorption and ensuring the integrity of the material in wet or humid conditions.

-

Thermal Stability: These sheets have good thermal stability, meaning they can withstand a wide range of temperatures without degrading. This is particularly useful in applications that involve exposure to high or low temperatures.

-

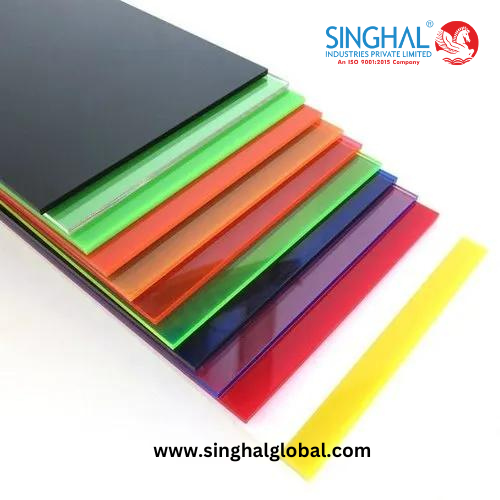

Versatility: PP sheets can be easily molded, cut, and welded, making them suitable for a variety of applications. They can also be produced in different colors, thicknesses, and surface finishes.

-

Cost-Effective: The production of PP sheets is relatively economical, making them a cost-effective choice for many industries. Their durability and reusability further enhance their cost-efficiency.

Applications of PP Sheets

-

Packaging: One of the most common uses of PP sheets is in the packaging industry. They are used to create packaging materials such as boxes, trays, and containers. The durability and moisture resistance of PP sheets help protect products during transportation and storage.

-

Automotive: In the automotive industry, PP sheets are used for interior and exterior components, including door panels, dashboards, and protective covers. Their lightweight nature helps improve fuel efficiency, while their durability ensures longevity.

-

Construction: PP sheets are used in construction for applications such as wall cladding, roofing, and insulation. Their chemical resistance makes them ideal for use in environments where exposure to harsh chemicals is a concern.

-

Advertising and Signage: The smooth surface of PP sheets makes them suitable for printing, making them popular in the advertising and signage industry. They are used to create signs, displays, and banners.

-

Stationery: PP sheets are used to manufacture various stationery products such as folders, binders, and protective covers. Their durability and resistance to wear and tear make them ideal for these applications.

-

Medical: In the medical field, PP sheets are used to produce items such as sterilization trays, medical packaging, and protective barriers. Their chemical resistance and ability to withstand sterilization processes make them suitable for these applications.

-

Agriculture: PP sheets are used in agriculture for applications such as greenhouse panels, irrigation systems, and protective barriers. Their durability and resistance to moisture and chemicals make them ideal for outdoor use.

-

Textiles: In the textile industry, PP sheets are used as backing material for carpets and rugs. Their moisture resistance helps prevent mold and mildew growth, extending the life of these products.

-

Food Industry: PP sheets are used in the food industry for creating cutting boards, food trays, and packaging materials. Their chemical resistance and non-toxic nature make them safe for contact with food.

Why Choose PP Sheets?

-

Adaptability: PP sheets can be adapted to a wide range of applications due to their versatility. They can be easily molded, cut, and welded to meet specific requirements.

-

Performance: The performance characteristics of PP sheets, such as their durability, chemical resistance, and moisture resistance, ensure that they can handle various challenges effectively.

-

Cost-Efficiency: PP sheets offer a cost-effective solution for many industries. Their economical production, coupled with their durability and reusability, provides significant cost savings.

-

Safety: PP sheets are non-toxic and safe for use in applications that involve contact with food and medical supplies. Their chemical resistance also ensures that they do not react with substances they come into contact with.

-

Environmental Benefits: PP sheets can be recycled, contributing to environmental sustainability. By choosing PP sheets, businesses can reduce their environmental footprint and support eco-friendly practices.

Conclusion

PP sheets are a versatile, durable, and cost-effective material that has become essential in various industries. Their unique properties, including chemical resistance, moisture resistance, and thermal stability, make them suitable for a wide range of applications, from packaging and automotive components to construction and medical supplies. The adaptability, performance, and environmental benefits of PP sheets ensure their continued popularity and relevance in modern industry. By choosing Pp sheets manufacturer in india, businesses can leverage a high-quality material that meets diverse needs while supporting sustainable practices.

Frequently Asked Questions (FAQs):

Q1: What makes PP sheets from Singhal Industries a suitable choice for various applications?

PP sheets from Singhal Industries are highly versatile due to their unique properties such as durability, chemical resistance, lightweight nature, and moisture resistance. These characteristics make them ideal for a wide range of applications, including packaging, automotive components, construction materials, advertising signage, and more. The adaptability of PP sheets, which can be easily molded, cut, and welded, further enhances their suitability for diverse industries.

Q2: How do PP sheets from Singhal Industries support environmental sustainability?

PP sheets from Singhal Industries contribute to environmental sustainability because they are recyclable. The production process of these sheets is economical, reducing resource consumption, and their durability and reusability extend their lifecycle, minimizing waste. By choosing PP sheets, businesses can reduce their environmental footprint and support eco-friendly practices, aligning with modern sustainability goals.

Q3: What are the primary benefits of using PP sheets from Singhal Industries in packaging and construction?

PP sheets from Singhal Industries offer several key benefits for packaging and construction. In packaging, their durability and moisture resistance ensure the protection of products during transportation and storage. In construction, their chemical resistance and thermal stability make them suitable for demanding environments, such as wall cladding, roofing, and insulation. Additionally, the lightweight nature of PP sheets helps reduce transportation costs and ease handling, making them a cost-effective and efficient choice for both industries.

- Questions and Answers

- Opinion

- Motivational and Inspiring Story

- Technology

- Live and Let live

- Focus

- Geopolitics

- Military-Arms/Equipment

- Security

- Economy

- Beasts of Nations

- Machine Tools-The “Mother Industry”

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film/Movie

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Health and Wellness

- News

- Culture