Explore the Versatility of Rigid Packaging Boxes

Rigid packaging boxes are versatile, sturdy, and durable containers designed to protect and present delicate products. However, these boxes are incredibly resilient and robust, protecting products from environmental elements like dampness and damage. Because they are made of sturdy materials like cardboard, paperboard, or corrugated board, these boxes preserve the inside product's integrity.

Moreover, their inflexible design keeps things from crushing or deforming, guaranteeing they reach their destination undamaged. These boxes can be customized with different branding options to meet the unique needs of organizations.

Furthermore, rigid packaging boxes are a great way to promote your business because they act as a blank canvas to display product details. This factor contributes to a more impactful and memorable product experience. Also, these boxes attract more clientele by strengthening brand identification and increasing brand visibility.

Packaging Styles for Rigid Box Packaging

Top-load/Telescope Boxes with Corners

The top-load boxes have a lid that covers the bottom edge almost entirely (full telescope) or the base halfway (partial telescope). Complete telescope box covers feature semi-circular or thumb cuts to facilitate their removal from the base. So, the version of the complete telescope box is the drawer-style box. They also serve as the shell and slide or a tray with a sleeve.

This kind of box is comparable to a conventional matchbox. Instead of a top lid, it features a slipcase that covers the base or "tray" of matches. However, they are appropriate for objects whose contents are placed flat rather than upright and must be preserved or damaged. These products include jewelry, smartphones, and some types of cosmetics.

In contrast, a half telescope box is the traditional shoebox with a lid usually one inch deep. This type is used to construct many high-end gift boxes, windowless shirt boxes, and opulent cosmetic packaging.

Top-load/Telescope Boxes without Corners

These are rigid cylindrical box types with either telescoping or shoulder-neck openings, also known as rolled-edge tube packaging (or simply tube packing). They work well as packing materials for powdered commodities, irregularly shaped objects, bottles, markers, and other circular items. Additionally, brands may think of them as substitutes for metal packaging. Also, they are rigid tube boxes with metal or plastic lids. Their interiors may include foils or plastic inserts.

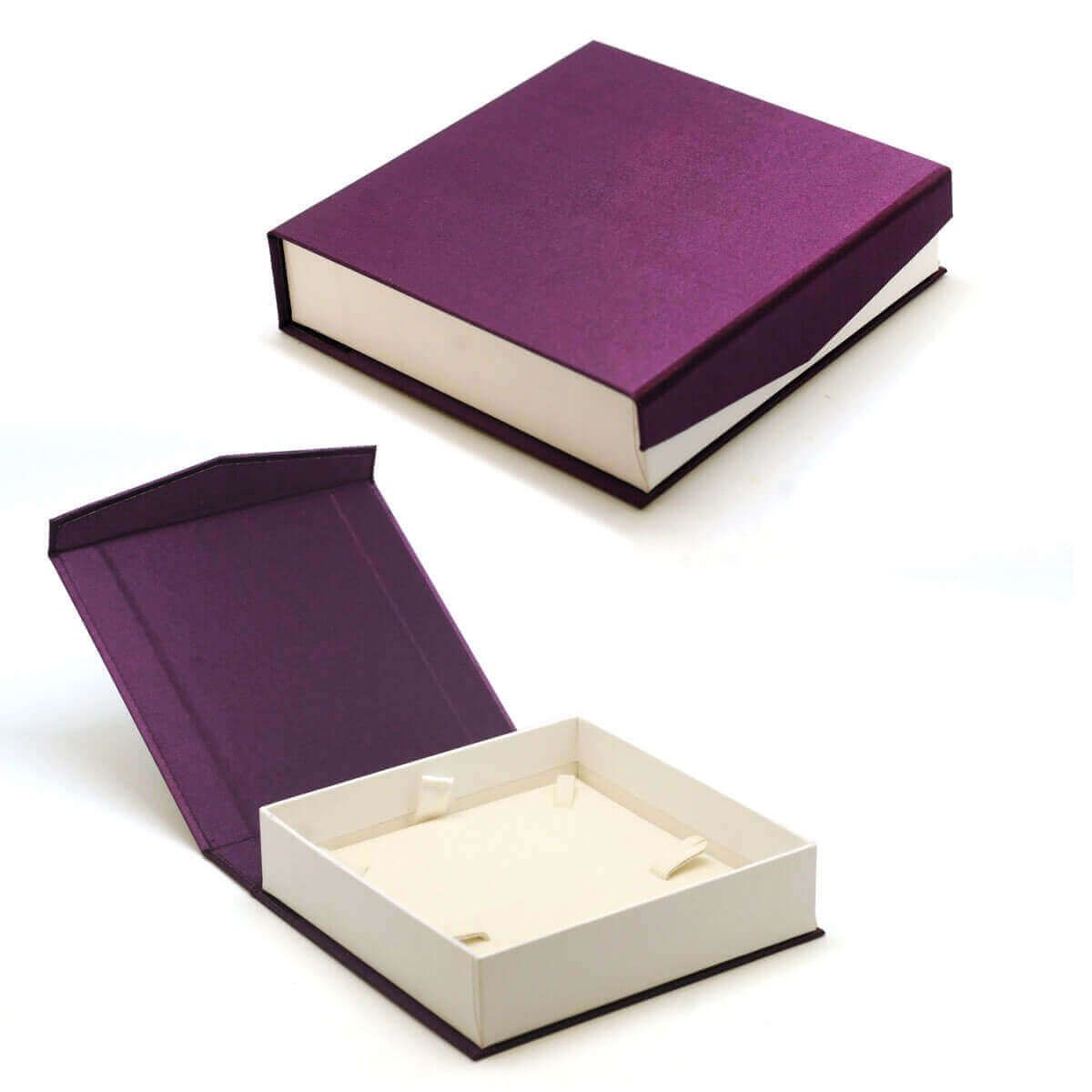

Lid Boxes with a Hinge

The hinged lid boxes are affixed permanently with base covers. They shut with a magnetic strip, weight, or another fastening mechanism. Some of these boxes, like the flip-top and cigar boxes, feature lids without a lid covering the box's base. The book-style box has the same covers as a cigar box. But with the box closing, the covering flap extends slightly above the base, giving the impression that it is a hardcover book.

On the other hand, the partial lid box design features a lid that extends partially or to the base's bottom edge. For example, a cloth or other lining may cover the hinge joint in certain hinged lid boxes.

Elements That Induce Excessive Costs for Rigid Boxes

Entirely printed and labeled corrugated or folding carton boxes are less expensive than custom rigid boxes. The reason is that these boxes are constructed from high-end materials to increase rigidity for fragile products. But the higher cost can arise from the following, as indicated and described in the preceding sections:

Materials Consideration

Construction of rigid packaging boxes from more expensive chipboard thicker than standard, foldable carton packing. They are available in many hues, such as black and white, with natural chipboard being the least costly. The ultimate cost is also influenced by the paper and finish you select for the wrap. Full-finish boxes are more expensive because they require more paper to cover the chipboard.

Furthermore, metallic, neon and other specialized inks cost more than ordinary inks for finishes. Larger surfaces will, of course, require more materials. The total cost includes labels, magnetic strips, or ribbon pulls.

Construction Cost

The construction cost of the rigid box's final bill includes using specially designed dies for cutting, foil stamping, embossing, and debossing. The price will increase if your packaging box has multiple sections, a unique form, many colors, or other printing techniques. Also, separate cutting dies, and molds are needed for inserts.

Additionally, rigid box manufacturers fold sections of your custom rigid boxes, paste their sides, and wrap them using unique machinery. However, complex packing or the addition of inserts which might be composed of plastic, cardboard, foam, or tissue may call for manual work.

Consider Storage Space

Custom rigid boxes wholesale require more space for storage because they are delivered pre-assembled in their finished state. Find out if the packaging business you use provides managed inventory services. This point is maintaining a certain stock level for you and shipping items only when needed. Additionally, you can look for any space in your company warehouse.

How You Can Reduce the Cost of Manufacturing Rigid Boxes

When delivering rigid boxes on a budget, take into account these workarounds:

Select Standard Thickness and Sizes

A more intricate construction will always fetch a higher price. Use a standard size and thickness that will require less customization from your manufacturing partner if this is outside your budget. They can purchase standard chipboards more easily in quantity or have enough of them in stock to fulfill your order for a custom rigid box. You will save money as a result, and they will begin production earlier and complete the job more quickly.

Select a More Minimal Design

Do you want to adhere to your initial idea? Perhaps you could condense the language and lessen the pictures so they fit into the tiny cardboard container. Try moving the goods around or taking them apart to see if a smaller box fits your needs better. Utilizing smaller rigid boxes allows you to place more of your products on a store shelf at once.

Select Lighter Materials

When it comes to chipboard thickness, be aware of your possibilities. Next, discuss with the design or manufacturing team how a thinner version can help your advertising and functional needs.

Select Digital Printing for Low-Summary Operations

Digital printing is more economical, even though it's not as high-quality as offset printing, especially if your design is straightforward and minimalist.

Minimize Extravagance

· Consider including a viewing window. In the primary package, the artwork, such as the label on your bottle or plastic casing, and a cut-out zone within the box may be less expensive than embossing or foil stamping.

· Minimize embossing or foil-stamped areas. Each square-inch box folding raises the price. Select the relevant components for these finishes.

· Choose a low-gloss finish and water-based coatings. Coatings with glitter and UV protection cost extra. Although lamination is well-known for its high level of moisture protection, a low- or semi-gloss finish can be an acceptable substitute.

Sum-Up

Wholesale rigid packaging boxes are the best option for companies looking to improve brand recognition and product protection. Because of their adaptability and branding opportunities, these custom boxes are more appropriate answers to various packaging-conscious industries. However, rigid packaging boxes maximize the packaging experience for both customers and businesses. Additionally, they protect fragile goods during transportation and improve brand visibility on shop shelves.

- Questions and Answers

- Opinion

- Motivational and Inspiring Story

- Technology

- Live and Let live

- Focus

- Geopolitics

- Military-Arms/Equipment

- الحماية

- Economy

- Beasts of Nations

- Machine Tools-The “Mother Industry”

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film/Movie

- Fitness

- Food

- الألعاب

- Gardening

- Health

- الرئيسية

- Literature

- Music

- Networking

- أخرى

- Party

- Religion

- Shopping

- Sports

- Theater

- Health and Wellness

- News

- Culture