What is CNC Machining? A Guide to Its Role in Custom Manufacturing

CNC (Computer Numerical Control) machining is a transformative technology that has revolutionized the custom manufacturing industry. This process, which involves the use of computers to control machine tools, allows manufacturers to produce precise and complex parts with incredible efficiency. CNC machining is integral to industries such as aerospace, automotive, medical device production, and electronics, providing them with the means to create customized parts quickly and accurately. But what exactly is CNC machining, and how does it fit into the broader world of custom manufacturing?

In this article, we’ll explore what CNC machining is, how it works, and the role it plays in custom manufacturing. By the end of this guide, you’ll have a solid understanding of why this technology is a game-changer for manufacturers and why it’s so crucial to the production of high-precision custom parts. Whether you're new to the concept or looking to deepen your knowledge, this guide will provide valuable insights into the fascinating world of CNC machining.

Understanding What CNC Machining Is

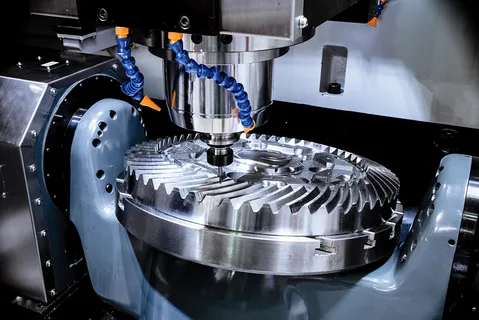

CNC machining, short for Computer Numerical Control machining, is a manufacturing process in which computers are used to control the movement and operation of machine tools. This process includes cutting, drilling, milling, and turning, all of which are used to shape material into specific parts or products. Unlike traditional manual machining, where operators directly control the tools with hands and levers, What is CNC Machining follow programmed instructions to execute tasks automatically, resulting in higher accuracy and repeatability.

The process starts with the design of a part, which is typically created using Computer-Aided Design (CAD) software. The CAD model is then translated into a set of coordinates that guide the CNC machine to create the desired shape. These coordinates are part of a numerical code called G-code, which dictates the specific movements the machine must make. Once the machine receives this code, it begins the manufacturing process, performing the necessary operations on the raw material to create the final part.

The Different Types of CNC Machines

CNC machining encompasses a variety of machines, each designed for different tasks in the custom manufacturing process. The most common types of CNC machines include CNC mills, CNC lathes, CNC routers, and CNC grinders. Each of these machines has its own distinct set of capabilities and uses in the production of custom parts.

CNC Mills: These machines use rotary cutters to remove material from a workpiece. They are versatile and can handle a variety of materials, including metals, plastics, and composites. CNC mills can perform multiple functions, such as drilling, tapping, and boring, which makes them ideal for creating complex, detailed parts.

CNC Lathes: In contrast to mills, CNC lathes are used primarily for turning operations. The workpiece is rotated while a cutting tool shapes the material. CNC lathes are commonly used to create cylindrical parts such as shafts, rods, and tubes, and are essential for industries that require precise, round components.

The Advantages of CNC Machining in Custom Manufacturing

CNC machining offers numerous advantages, particularly in custom manufacturing. The precision and flexibility it offers are unmatched by traditional manufacturing methods. One of the key benefits is the high level of accuracy and repeatability it provides. CNC machines can produce parts with tight tolerances, ensuring that each part is identical to the last. This is crucial in industries where precision is paramount, such as aerospace and medical device manufacturing.

Additionally, CNC machining enables rapid prototyping and reduced lead times, which is vital in the fast-paced world of custom manufacturing. With CNC machining, manufacturers can quickly create prototypes, test designs, and make necessary adjustments before moving to full-scale production. This accelerates the development process, reduces waste, and ensures that the final product meets the required specifications without unnecessary delays.

CNC Machining’s Role in the Custom Manufacturing Process

CNC machining plays a critical role in the custom manufacturing process, especially when it comes to producing low to medium-volume, highly customized parts. Unlike mass production techniques, which focus on producing large quantities of identical items, CNC machining is ideal for creating one-off or small-batch products that require unique specifications.

With CNC machining, manufacturers have the flexibility to produce a wide variety of parts, from simple components to complex geometries. This versatility is particularly valuable when working with custom designs that demand specific materials, dimensions, or shapes. CNC machines can work with a broad range of materials, including metals like aluminum, steel, and titanium, as well as plastics and composites, making them suitable for almost any custom manufacturing need.

CNC Machining in the Future of Custom Manufacturing

As technology continues to advance, the future of CNC machining looks promising. With the advent of Industry 4.0, which emphasizes automation, data exchange, and smart manufacturing, CNC machining is becoming even more integrated into the broader manufacturing ecosystem. The use of IoT (Internet of Things) devices, machine learning algorithms, and real-time data analytics is enhancing the capabilities of CNC machines, allowing for even greater precision, efficiency, and flexibility.

Furthermore, developments in multi-axis CNC machines are enabling manufacturers to create even more intricate and complex parts in a single setup. These machines can perform operations along multiple axes simultaneously, which significantly reduces production time and increases the accuracy of the parts. As CNC technology continues to evolve, its role in custom manufacturing will only grow, allowing manufacturers to meet the increasing demand for customized, high-quality products.

Conclusion

In conclusion, CNC machining is a vital process in custom manufacturing that combines precision, flexibility, and efficiency. Understanding what CNC machining is and how it works is essential for anyone involved in the manufacturing industry. From its role in creating complex parts to its advantages in reducing lead times and improving accuracy, CNC machining is at the forefront of modern manufacturing techniques.

As technology continues to advance, CNC machining will likely become even more indispensable in the production of custom parts. Whether you're involved in aerospace, medical device manufacturing, or any other field requiring precision parts, CNC machining is likely to be a crucial part of your manufacturing strategy. Embracing this technology is key to staying competitive in an ever-evolving industry.

- Questions and Answers

- Opinion

- Motivational and Inspiring Story

- Technology

- Live and Let live

- Focus

- Geopolitics

- Military-Arms/Equipment

- Security

- Economy

- Beasts of Nations

- Machine Tools-The “Mother Industry”

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film/Movie

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Health and Wellness

- News

- Culture