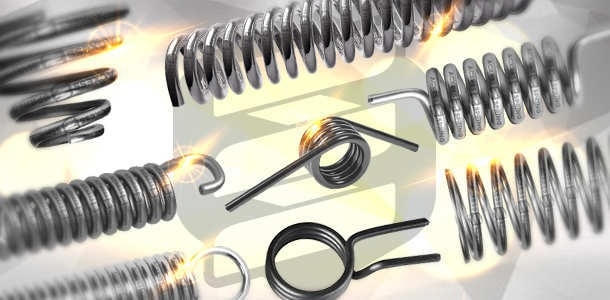

Custom Heavy Duty Compression Springs for Industrial Applications

Compression springs play a critical function in a big selection of industrial packages, offering pressure, stability, and motion inside mechanical systems. These specially designed springs are constructed to resist intense strain, temperature changes, and demanding operating conditions, making them necessary for industries that require reliable and durable components.

What is Heavy Duty Compression Springs?

Compression springs are mechanical features designed to resist compressive forces, transforming potential energy into kinetic energy when decompressing. Heavy duty compression springs are designed for applications that require more power and strength. Heavy duty compression springs are typically produced from high-carbon steel, chrome steel, or alloy metal to provide the tensile strength and lasting durability necessary throughout a heavy duty industrial application.

Applications in Industrial Sectors

1. Automotive Industry

Within the automotive industry, heavy duty compression springs are typically found in a variety of suspension systems, engine parts, and braking systems. They spring to absorb shock, maintain car balance, and lead to smoothly functioning features under various road conditions. Custom springs are developed for specific vehicle requirements, including performance, safety, and durability.

2. Aerospace

Aerospace applications require additives that perform in extreme conditions. Heavy duty compression springs are used in plane landing gear structures, engine components, and cabin pressurization structures. These springs want to be incredibly resilient to temperature fluctuations, vibration, and the heavy masses experienced at some stage in takeoff, flight, and landing.

3. Construction and Heavy Machinery

In the construction enterprise, large compression springs are found in hydraulic systems, cranes, bulldozers, and other machinery. They are used to soak up the shock and decrease the effect of heavy hundreds, ensuring the smooth functioning of large-scale operations. Heavy duty stock compression springs are also usually used in the creation machinery for their high load-bearing potential and sturdiness.

4. Oil and Gas

The oil and gasoline enterprise demands heavy duty compression springs for drilling rigs, pumps, and valve systems. These springs have to endure harsh environmental situations, such as excessive pressures, severe temperatures, and corrosive environments. Customization of stainless steel compression springs guarantees that they can be carried out optimally, even within the maximum hard environments.

5. Manufacturing and Automation

Custom compression springs by size and length are also utilized in production and automation systems, including conveyors, robotic arms, and machine presses. These springs are designed to deal with the heavy duty cycles and intense forces that are commonplace in industrial production traces.

Benefits of Custom Heavy Duty Compression Springs

1. Enhanced Performance: Custom-designed springs can meet the proper requirements of any application, ensuring advanced overall performance and long-lasting functionality. By specifying the fabric, dimensions, and cargo necessities, companies can optimize their systems for maximum performance.

2. Durability: Industrial applications frequently contain high-pressure conditions. Heavy duty compression springs, while custom-designed for these situations, can endure extra cycles and wear, presenting a far longer lifespan as compared to conventional springs.

3. Cost-Effectiveness: Custom springs, even though they begin with more steeply priced than off-the-shelf solutions, provide higher performance and fewer preservation issues ultimately. Their ability to address precise masses and operational situations approach fewer breakdowns, upkeep, and replacements.

4. Design Flexibility: Custom springs can be designed to fit unique areas and accommodate specific operational needs. Whether the application calls for a particular load potential or a spring able to withstand extreme temperatures, custom answers offer the power to meet diverse industrial necessities.

Conclusion

From this article, you can recognize that in business packages, the need for robust, long-lasting, and noticeably efficient components is crucial. Their ability to withstand intense situations and deliver reliable overall performance makes them the quality part of the machine and ensures long-time period operational efficiency and protection.

You specialize in presenting high-quality, custom, heavy duty compression spring solutions tailor-made to your unique necessities. Contact them today to study more about how they permit you to locate the perfect spring for your heavy duty programs.

- Questions and Answers

- Opinion

- Motivational and Inspiring Story

- Technology

- Live and Let live

- Focus

- Geopolitics

- Military-Arms/Equipment

- Безопасность

- Economy

- Beasts of Nations

- Machine Tools-The “Mother Industry”

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film/Movie

- Fitness

- Food

- Игры

- Gardening

- Health

- Главная

- Literature

- Music

- Networking

- Другое

- Party

- Religion

- Shopping

- Sports

- Theater

- Health and Wellness

- News

- Culture