An In-Depth Analysis of Waterproof Capabilities in Non Woven White Bags

Non Woven White Bags, known for their versatility and eco-friendliness, are widely used in various applications, from retail packaging to agricultural uses. One of the critical aspects of these bags that often comes under scrutiny is their waterproof performance. The waterproof capability of Non Woven White Bags is a significant factor that determines their suitability for specific uses, particularly in environments where moisture resistance is essential. This article aims to explore the waterproof properties of Non Woven White Bags in detail, examining the materials, manufacturing processes, and testing methods that contribute to their water resistance.

The primary material used in the production of Non Woven White Bags is polypropylene, a synthetic polymer known for its strength and resistance to moisture. This material's inherent hydrophobic nature plays a crucial role in the bags' waterproof performance. However, the degree of waterproofing can vary depending on the manufacturing process and the specific treatment applied to the fabric. Some Non Woven White Bags are coated with a thin layer of polyethylene, which significantly enhances their waterproof capabilities. This coating creates a barrier that prevents water molecules from penetrating the fabric, making the bags suitable for applications where water resistance is paramount.

The manufacturing process of Non Woven White Bags involves several steps that can impact their waterproof performance. Spunbond and Melt blowing methods are two common methods used to create the non-woven fabric. Spunbond involves the extrusion of polymers through fine jets to form long, continuous filaments that are then laid down onto a moving screen, creating a web of fibers. This web is then bonded together using heat, pressure, or adhesive to create a strong, non-woven fabric. Melt blowing method, on the other hand, uses high-velocity hot air to form a web of fibers, which is then bonded similarly. The choice of method can affect the bag's density and porosity, which in turn influence its ability to repel water.

To further enhance the waterproof properties of Non Woven White Bags, some manufacturers apply a lamination process. This involves adhering a layer of film, such as polyethylene or polyurethane, to the non-woven fabric. The lamination process creates a barrier that is highly resistant to water, making the bags suitable for use in wet environments or for storing moisture-sensitive items.

Quality control plays a vital role in ensuring the waterproof performance of Non Woven White Bags. Manufacturers conduct various tests to evaluate the bags' water resistance. These tests may include water droplet tests, where water droplets are placed on the bag's surface to assess how quickly they bead up and roll off. Hydrostatic pressure tests are also conducted to determine the bag's ability to withstand water pressure over time. These tests help manufacturers identify any weaknesses in the bag's construction and make necessary adjustments to the production process.

In conclusion, the waterproof performance of Non Woven White Bags is a complex characteristic influenced by the choice of material, manufacturing process, and specific treatments applied to the fabric. Understanding these factors is crucial for manufacturers to produce bags that meet the waterproof requirements of their target applications. As the demand for Non Woven White Bags continues to grow, so does the need for high-quality, waterproof bags that can withstand the challenges of various environments. Manufacturers must continue to innovate and refine their processes to ensure that Non Woven White Bags remain a reliable and versatile option for consumers and industries alike.

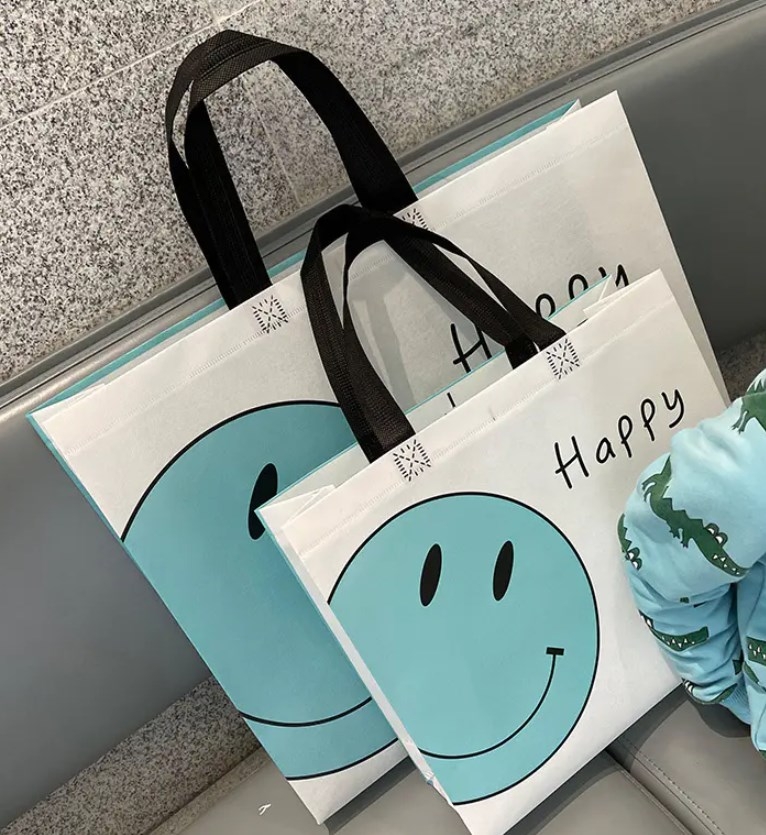

Colour: Various colours

Pattern: Customizable

Width: 5 cm~60 cm

Length: Customizable

Thickness: 0.08 mm- 1.2 mm (customisable)

Material: Non-woven

Process: Die-cutting

Application: Clothing, food, daily necessities, cosmetics, cultural products, etc.

- Questions and Answers

- Opinion

- Motivational and Inspiring Story

- Technology

- Live and Let live

- Focus

- Geopolitics

- Military-Arms/Equipment

- Sécurité

- Economy

- Beasts of Nations

- Machine Tools-The “Mother Industry”

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film/Movie

- Fitness

- Food

- Jeux

- Gardening

- Health

- Domicile

- Literature

- Music

- Networking

- Autre

- Party

- Religion

- Shopping

- Sports

- Theater

- Health and Wellness

- News

- Culture