Precision and Versatility: Exploring the Capabilities of UV Laser Marking and Engraving Technology

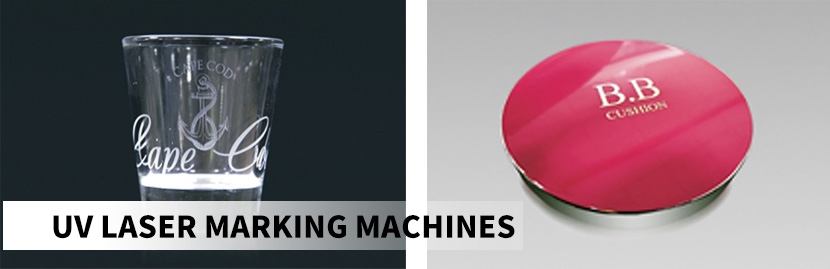

In the ever-evolving field of industrial marking and micro-processing, UV laser technology stands out for its precision, non-contact process, and suitability for delicate materials. Compared to fiber or CO₂ lasers, UV lasers operate at a much shorter wavelength, offering cleaner edges and minimal thermal impact. This makes them ideal for industries like electronics, medical devices, and packaging, where accuracy is paramount.

One of the most widely used wavelengths in the UV range is the 365nm laser. Operating in the near-ultraviolet spectrum, it enables high-contrast, high-resolution results on a variety of substrates including plastics, glass, ceramics, and even some metals. The low heat input ensures that the surrounding material remains unaffected, preserving product integrity.

UV laser marking has become an essential process in applications that demand fine detail and permanence. It is frequently used to mark serial numbers, barcodes, and logos on microchips, connectors, and pharmaceutical packaging. Since UV lasers produce a “cold” beam, they can process heat-sensitive materials without causing burns, melting, or carbonization.

For even more demanding micro-structuring tasks, the deep UV laser—typically operating below 300nm—takes the performance a step further. With finer beam spots and higher absorption rates in organic and transparent materials, deep UV systems are often applied in advanced electronics manufacturing, OLED screen repair, and microfluidics.

Meanwhile, UV laser engraving is gaining traction as an alternative to traditional mechanical methods. It provides unmatched precision and aesthetic quality, making it suitable for intricate designs on watches, medical instruments, and optical components. The engraved areas are clean, legible, and resistant to wear, which is critical for traceability and compliance.

At the heart of all these innovations lies the UV laser source. Advancements in diode-pumped solid-state technology and all-solid-state UV lasers have led to longer service life, higher beam quality, and reduced maintenance. Whether integrated into stand-alone machines or high-volume production lines, a reliable UV laser source is crucial for consistent output and cost efficiency.

As industries move toward finer detail and higher standards, the role of UV lasers continues to grow. Whether it's UV laser marking on pharmaceuticals, UV laser engraving of consumer electronics, or using 365nm lasers for circuit boards, the demand for precise, contactless processing is pushing UV technology to the forefront.

- Questions and Answers

- Opinion

- Motivational and Inspiring Story

- Technology

- Live and Let live

- Focus

- Geopolitics

- Military-Arms/Equipment

- Segurança

- Economy

- Beasts of Nations

- Machine Tools-The “Mother Industry”

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film/Movie

- Fitness

- Food

- Jogos

- Gardening

- Health

- Início

- Literature

- Music

- Networking

- Outro

- Party

- Religion

- Shopping

- Sports

- Theater

- Health and Wellness

- News

- Culture