Motor Lamination Market: The Heart of Electric Motor Efficiency

Motor laminations are thin sheets of magnetic steel or silicon steel that are used in the construction of electric motors. These laminated sheets help reduce energy loss, increase efficiency, and enhance the performance of motors. Laminations are key to reducing eddy current losses and improving motor efficiency, making them an essential component in electric motors used across a variety of industries such as automotive, industrial machinery, home appliances, and renewable energy systems.

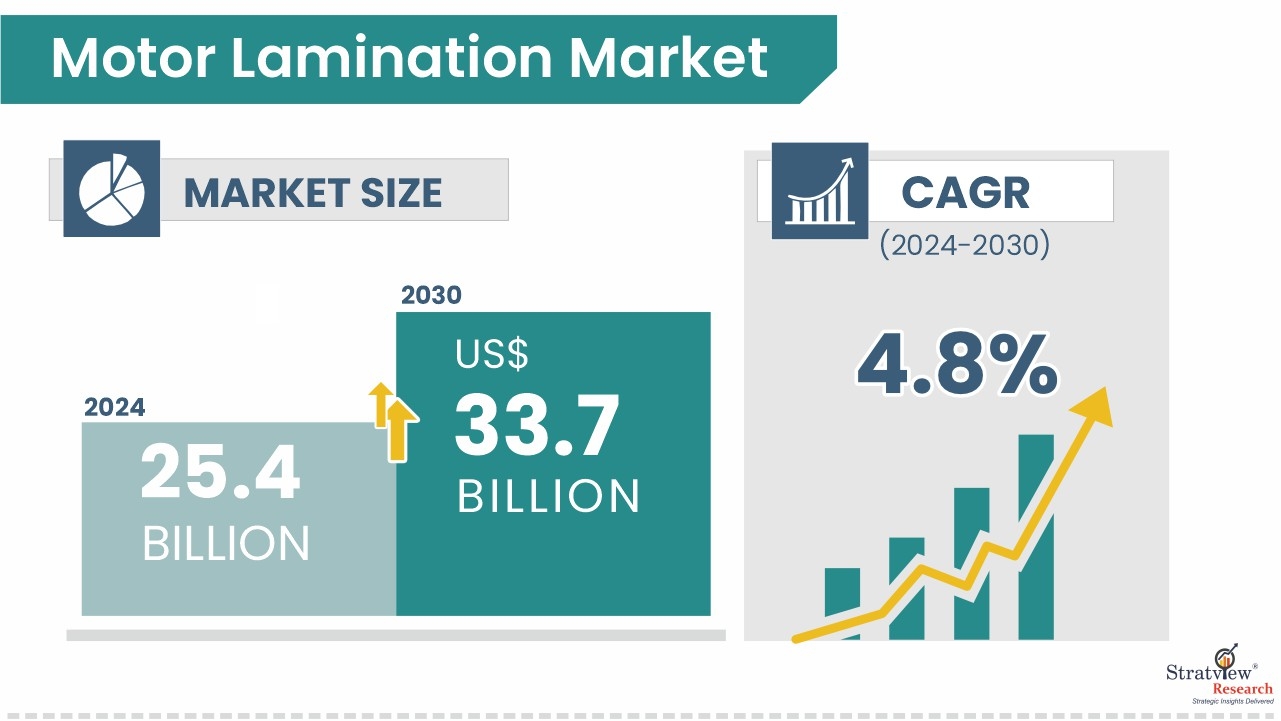

According to Stratview Research, the Motor Lamination Market is projected to grow at a CAGR of 4.8% from 2024 to 2030, reaching a market value of USD 33.7 billion by 2030. This growth is driven by the increasing adoption of electric motors in various applications, particularly in the automotive and renewable energy sectors.

Request a sample report to preview our in-depth analysis:

https://stratviewresearch.com/Request-Sample/4107/motor-lamination-market.html#form

What Are Motor Laminations?

Motor laminations are thin layers of steel that are stacked together to form the core of an electric motor. These laminations are coated with a thin layer of insulating material to reduce electrical losses such as eddy currents and hysteresis losses. By reducing these losses, motor laminations significantly improve the overall efficiency and performance of electric motors, which is crucial in applications that require high power output and low energy consumption.

Applications of Motor Laminations

- Automotive Industry:

In the automotive sector, electric motors powered by motor laminations are used in electric vehicles (EVs), hybrid vehicles, and power steering systems. Motor laminations help improve motor efficiency and reduce energy consumption in electric drivetrains, making them crucial for the transition to sustainable transportation. - Industrial Machinery:

Motor laminations are used in industrial machinery to power pumps, fans, compressors, and conveyors. These motors require high efficiency and reliability to operate in demanding industrial environments, where downtime and energy wastage can lead to significant costs. - Renewable Energy Systems:

In wind turbines and solar inverters, motor laminations are used to enhance motor efficiency and reduce power losses. The growing adoption of renewable energy is driving the demand for high-performance electric motors equipped with motor laminations.

Market Drivers for Motor Laminations

- Growing Demand for Electric Vehicles (EVs):

The shift towards electric vehicles is one of the key drivers of the motor lamination market. As EV adoption increases, so does the demand for efficient electric drivetrains, where motor laminations play a critical role in reducing energy consumption and improving motor performance. - Energy Efficiency Regulations:

Increasingly stringent energy efficiency regulations across industries are driving the adoption of high-performance motors equipped with motor laminations. These regulations require manufacturers to develop efficient and low-power-consumption motor solutions. - Technological Advancements in Motor Design:

Technological advancements in motor design, material science, and manufacturing processes are enhancing the performance of motor laminations. Innovations in silicon steel and insulating coatings are further driving the adoption of motor laminations in various applications.

Challenges in the Market

- High Manufacturing Costs:

The production of motor laminations involves advanced manufacturing techniques and the use of high-quality materials such as silicon steel, which can increase production costs. This can limit the adoption of motor laminations in cost-sensitive applications. - Raw Material Supply Issues:

The availability and price volatility of raw materials such as steel and silicon can impact the overall cost and supply chain of motor laminations. Manufacturers must ensure a stable supply of high-quality materials to maintain production efficiency.

Conclusion

The Motor Lamination Market is poised for growth, driven by increasing demand for electric vehicles, industrial automation, and renewable energy systems. As energy efficiency continues to be a priority, the role of motor laminations in enhancing motor performance will remain crucial across various industries.

- Questions and Answers

- Opinion

- Motivational and Inspiring Story

- Technology

- Live and Let live

- Focus

- Geopolitics

- Military-Arms/Equipment

- Güvenlik

- Economy

- Beasts of Nations

- Machine Tools-The “Mother Industry”

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film/Movie

- Fitness

- Food

- Oyunlar

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Health and Wellness

- News

- Culture