Injection Molding Machine Market – Powering Precision Manufacturing

Injection molding machines are at the heart of mass production for plastic components, enabling high precision and repeatability. These machines are widely used across industries such as automotive, packaging, electronics, consumer goods, and healthcare. The injection molding machine market is witnessing steady growth as industries shift toward automation, lightweight components, and complex part geometries.

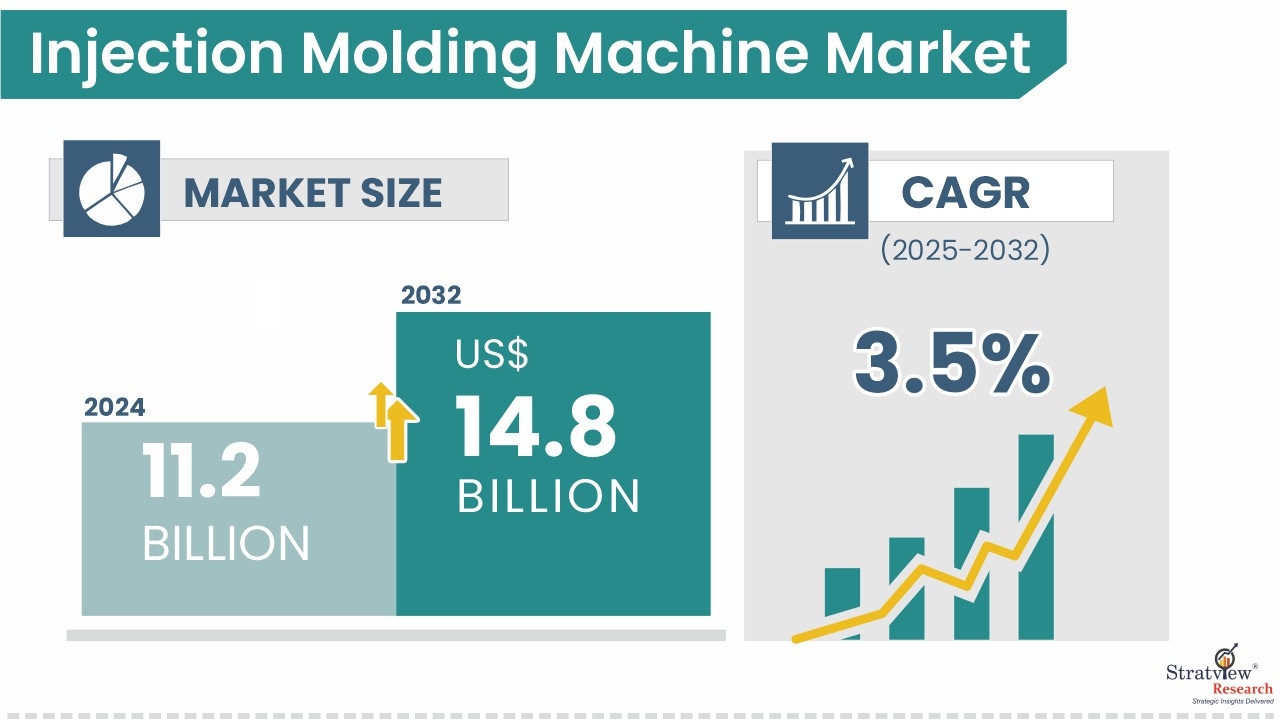

According to Stratview Research, the injection molding machine market was estimated at USD 11.2 billion in 2024 and is likely to grow at a CAGR of 3.5% during 2025-2032 to reach USD 14.8 billion in 2032.

Download the sample report here, to uncover in-depth insights.

https://stratviewresearch.com/Request-Sample/1146/injection-molding-machine-market.html#form

Key Drivers:

- Rising Demand from Automotive and Packaging Sectors: Lightweight plastic components are being increasingly used to reduce vehicle weight and improve fuel efficiency.

- Growth of Consumer Electronics: High-volume, precision parts are essential in mobile devices, wearables, and household electronics.

- Medical Device Manufacturing: The growing demand for disposable medical products and precision healthcare equipment supports market growth.

- Industrial Automation: Integration with robotics and AI is boosting productivity and efficiency across production lines.

Challenges:

- High Initial Investment: Advanced machines and auxiliary equipment require substantial upfront costs, limiting adoption for small and medium enterprises.

- Material Limitations: Not all polymers are suitable for injection molding, and bioplastics pose new process challenges.

- Energy Consumption: Traditional hydraulic machines are energy-intensive, leading to higher operational costs and environmental concerns.

Trends:

- Shift Toward Electric and Hybrid Machines: These offer better precision, lower energy use, and quieter operation.

- Smart Injection Molding: IoT-enabled machines allow real-time monitoring, predictive maintenance, and process optimization.

- Customization & Low-Volume Runs: The rise of niche product lines is encouraging flexible and modular molding solutions.

- Sustainability Focus: Manufacturers are exploring recycled materials and energy-efficient machinery to reduce their carbon footprint.

Conclusion:

The injection molding machine market is evolving with the demands of modern manufacturing. By investing in automation, smart technologies, and sustainable practices, machine makers and end users can unlock significant efficiency and competitive advantage.

- Questions and Answers

- Opinion

- Motivational and Inspiring Story

- Technology

- Live and Let live

- Focus

- Geopolitics

- Military-Arms/Equipment

- Security

- Economy

- Beasts of Nations

- Machine Tools-The “Mother Industry”

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film/Movie

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Health and Wellness

- News

- Culture