Unbreakable Threads: The Expanding Role of UHMWPE Fibers Across Industries

Ultra-High Molecular Weight Polyethylene (UHMWPE) fibers are renowned for their exceptional strength-to-weight ratio, abrasion resistance, and low coefficient of friction. With applications in ballistic protection, medical implants, ropes, nets, and industrial equipment, the UHMWPE fiber market is expanding rapidly, driven by demand for lightweight yet durable materials.

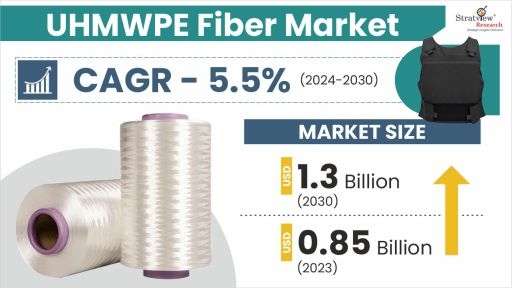

According to Stratview Research, the UHMWPE fiber market was estimated at USD 0.85 billion in 2023 and is likely to grow at a CAGR of 5.5% during 2024-2030 to reach USD 1.3 billion in 2030.

Request a sample report to preview our in-depth analysis.

https://stratviewresearch.com/Request-Sample/3878/uhmwpe-fiber-market.html#form

Drivers

- Defense & Ballistics: The fiber’s high impact resistance makes it ideal for body armor, helmets, and vehicle armor.

- Medical Industry Growth: UHMWPE fibers are used in orthopedic implants, including hip and knee replacements.

- Maritime & Industrial Use: High-strength ropes and nets made of UHMWPE are replacing traditional steel and nylon in offshore and shipping industries.

- Rising Sports Applications: From climbing ropes to cut-resistant gloves, the sports sector is increasingly adopting UHMWPE.

Challenges

- High Production Costs: The complex gel spinning process and raw material costs make UHMWPE more expensive than alternatives.

- Environmental Impact: Being a thermoplastic, UHMWPE poses recyclability issues and environmental disposal concerns.

- Limited Heat Resistance: UHMWPE has a low melting point, restricting its use in high-temperature applications.

Opportunities

- Green UHMWPE: Development of bio-based polyethylene for sustainable UHMWPE is gaining momentum.

- Lightweight Armor for Civil Use: As personal safety becomes a priority, civilian demand for body armor is growing.

- Emerging Economies: Growing defense budgets and medical advancements in countries like India and Brazil create new demand channels.

Trends

- Nanofiber Integration: Hybrid composites combining UHMWPE with nanomaterials are under research for enhanced performance.

- 3D Woven UHMWPE: Advanced weaving technologies improve fiber orientation and energy absorption for military gear.

Conclusion

UHMWPE fibers are poised for widespread adoption across sectors due to their unmatched durability and lightweight properties. With ongoing innovations and expanding use cases, the market is set to grow significantly.

- Questions and Answers

- Opinion

- Motivational and Inspiring Story

- Technology

- Live and Let live

- Focus

- Geopolitics

- Military-Arms/Equipment

- الحماية

- Economy

- Beasts of Nations

- Machine Tools-The “Mother Industry”

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film/Movie

- Fitness

- Food

- الألعاب

- Gardening

- Health

- الرئيسية

- Literature

- Music

- Networking

- أخرى

- Party

- Religion

- Shopping

- Sports

- Theater

- Health and Wellness

- News

- Culture