Electronics Corrosion Monitoring: Ensuring Reliability in Critical Environments

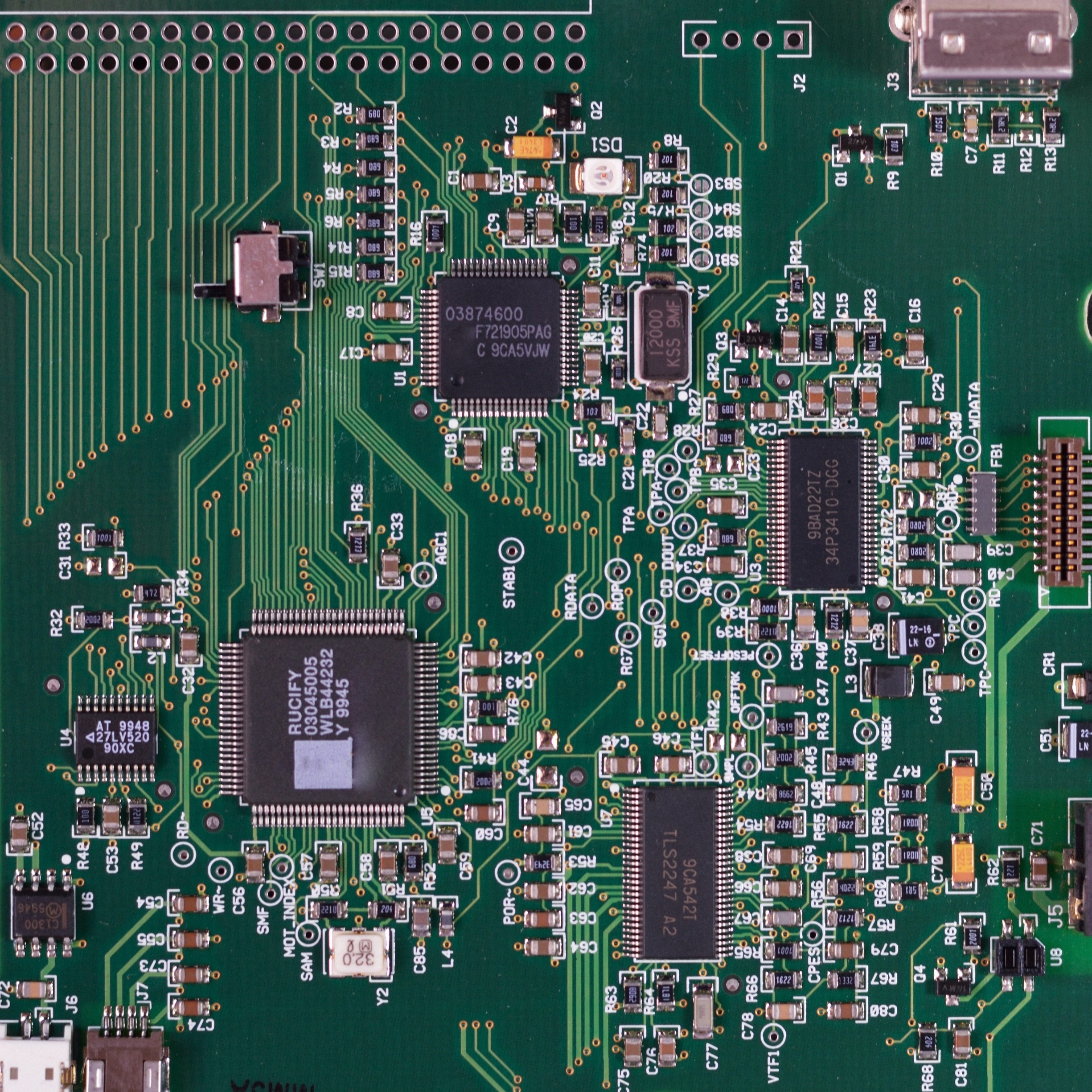

In the world of sensitive electronic infrastructure such as data centres, semiconductor manufacturing facilities, and medical labs electronics corrosion monitoring is not just a preventive measure; it’s a vital safeguard for operational continuity and asset longevity.

What Is Electronics Corrosion Monitoring?

Electronics Corrosion Monitoring refers to the continuous or periodic tracking of corrosive activity affecting electronic components and environments. At AQOZA, this translates into both online and offline monitoring solutions based on the ISA‑S71.04 standard, enabling proactive maintenance regimes that address corrosion before it compromises your systems.

Why It Matters

Corrosion often driven by industrial emissions like sulfur compounds, chlorides, or ozone can infiltrate data centres and control rooms, subtly eroding metallic traces or connectors. With the trend toward lead‑free electronics under RoHS directives, susceptibility to such damage has only increased. When left undetected, corrosion can lead to premature failures, costly repairs, and unplanned downtime.

AQOZA’s Dual-Mode Approach

AQOZA offers a comprehensive electronics corrosion monitoring portfolio with both online and offline options:

- Online Monitoring – AQOZA CORROSENSE Active 2.0:

- Utilizes Electrical Resistance (ER) technology to monitor air corrosivity in real time, tracking resistance changes across copper or silver sensors.

- Provides corrosion rate data categorized under ANSI/ISA‑S71.04 levels (G1–G3, GX), with live alerts, dashboard access, and environmental metrics temperature, humidity, and pressure for informed decision‑making.

- Offline Monitoring – ER P01 Corrosion Coupons:

- These passive coupons are deployed for around 30 days and then analyzed in AQOZA’s lab.

- Ideal for thorough periodic surveys, they deliver precise corrosion rate data and actionable insights for facilities where continuous monitoring may not be feasible.

Where These Solutions Shine

AQOZA’s electronics corrosion monitoring is tailored for a wide range of sectors:

- Data Centres

- Healthcare and Imaging Labs

- Petrochemical and Pharmaceutical Facilities

- Semiconductor Manufacturing

- Wastewater Treatment Plants

- Airports, Steel & Fertilizer Manufacturing, Paper & Pulp Industries

These systems help deliver early warnings, reduce equipment failure rates, ensure compliance, and protect high-value electronic hardware from invisible but destructive corrosion.

Benefits at a Glance

|

Feature |

Online Monitoring (Active) |

Offline Monitoring (Coupons) |

|

Mode |

Continuous real-time data |

Periodic (≈30-day) assessment |

|

Technology |

ER sensors, environmental tracking |

Passive ER-based films |

|

Ideal For |

Dynamic environments & predictive maintenance |

Baseline surveys, cost-conscious setups |

|

Output |

Live alerts, dashboards, severity grading |

Lab-analyzed corrosion rates |

Both options align with ISA‑S71.04, empowering organizations to monitor, manage, and mitigate corrosion in sensitive electronic settings with precision.

With AQOZA’s advanced electronics corrosion monitoring solutions, businesses can boost equipment uptime, extend service life, and eliminate the risk of unforeseen failures ensuring that electronics remain reliable, safe, and protected.

- Questions and Answers

- Opinion

- Motivational and Inspiring Story

- Technology

- Live and Let live

- Focus

- Geopolitics

- Military-Arms/Equipment

- Sicherheit

- Economy

- Beasts of Nations

- Machine Tools-The “Mother Industry”

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film/Movie

- Fitness

- Food

- Spiele

- Gardening

- Health

- Startseite

- Literature

- Music

- Networking

- Andere

- Party

- Religion

- Shopping

- Sports

- Theater

- Health and Wellness

- News

- Culture