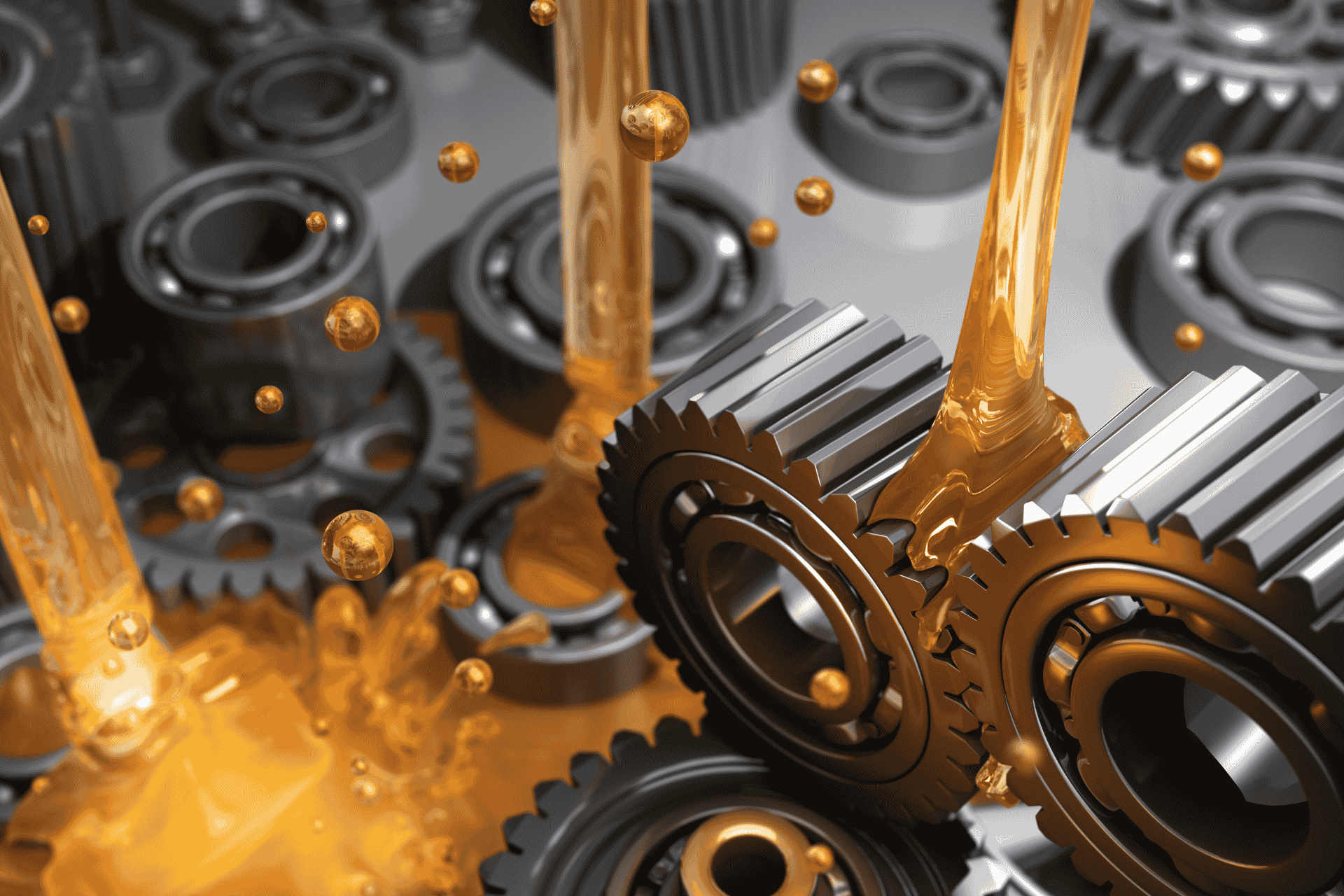

Oil Lubricants Distributors: What Sets the Best Apart & How to Partner with Top Lube Manufacturers

1. What Oil Lubricants Distributors Do Daily

Drawing on a decade of work in lubrication supply chains, here’s what oil lubricants distributors typically handle:

-

Sourcing & Inventory Management: Distributors must select lube manufacturers with high quality standards (API, ISO, SAE grades), ensure raw oils or blended oils are stored properly, and maintain a diverse stock of engine oils, industrial oils, greases, and specialty fluids.

-

Quality Control & Technical Services: Checking viscosity, additive compatibility, contamination; sometimes offering lab testing; advising users (OEMs, workshops, plant managers) on correct lubricant options.

-

Warehousing & Logistics: Safe storage with temperature control; efficient loading, bulk tanker transport or smaller packaging; managing wastage and shelf life.

-

Compliance & Certifications: Meeting regulatory requirements; maintaining product traceability; environmental compliance; safety in transport.

-

Customer Relations & Support: Educating customers about lube types, usage intervals; responding when equipment fails; offering custom lubrication schedules.

The more value a distributor adds (beyond just shipping oil), the more sustainable and profitable the business tends to be.

2. Understanding Lube Manufacturers: What to Ask

As an oil lubricants distributor, your choice of lube manufacturers’ll impact your reputation and profitability. Here are key questions to ask:

|

Question |

Reason It Matters |

|

What grades and specifications (API, SAE, ISO) do you meet? |

Ensures compatibility with customers’ equipment and regulatory demands. |

|

Do you blend your own lubricants or rely on third‑party blend plants? |

Gives insight into quality control and consistency. |

|

What certifications do you hold (ISO, OEM approvals, environmental)? |

Certification signals quality, reduces risk. |

|

How is your supply reliability and lead time? |

Delays in supply can disrupt distributor inventory and customers. |

|

Do you support technical training or offer product documentation and guidance? |

Enables you to educate your buyers, improving trust. |

|

Can you customize blends or packaging for regional or customer‑specific needs? |

Differentiation helps distributors to serve niche markets. |

3. Key Qualities of Top Distributors in This Sector

From my experience, top oil lubricants distributors share several qualities that make them stand out:

-

Strong network: Access to reliable transport, warehousing, quick reorder cycles.

-

Technical expertise: Ability to educate customers; correct application rather than one‑size‑fits‑all.

-

Brand trust & ethics: Working with reputable lube manufacturers; transparent labeling and pricing.

-

Flexibility: Serving customers from small workshops to large industrial plants; customized packaging (drums, pails, bulk).

-

After‑sales support: Handling performance feedback, warranty issues, proper disposal of used oil.

These qualities help maintain long‑term relationships and prevent reputational damage in an industry where oil failure or misapplication can cause costly machinery breakdowns.

4. Challenges in Distribution & How to Overcome Them

Working as an oil lubricants distributor isn’t without hiccups. Here are common challenges and ways to address them:

|

Challenge |

Solution |

|

Price volatility of base oils & additives |

Lock in supply contracts; negotiate with lube manufacturers; carry buffer inventory. |

|

Counterfeiting & adulteration |

Source from certified manufacturers; verify product markings; educate customers on genuine vs fake. |

|

Logistical issues in remote areas |

Build regional warehouses; use distribution hubs; partner with reliable carriers. |

|

Technical misuses (wrong lubricant type, mixing) |

Train sales/field staff; provide clear product guides; offer lab testing. |

|

Environmental & regulatory compliance |

Regular audits; proper disposal of used oil; compliance with local norms (e.g. regarding hazardous substances). |

5. How ApproLubes Positions Itself Among Oil Lubricants Distributors

(Based on internal practices and strengths—adjust as needed.)

ApproLubes, operating via approLubes.net, has built its distributor role with these strengths:

-

Consistent partnership with certified lube manufacturers who meet API, ISO, and OEM standards.

-

A well‑managed warehouse network with climate‑controlled storage to preserve oil integrity.

-

Skilled technical team that supports clients (workshops, industrial plants) with lubricant selection, usage interval guidance, and troubleshooting.

-

Transparent pricing and timely supply—bulk oil drums or small pack orders fulfilled quickly.

-

Customer‑centric service: from customized packaging to special blends for specific machinery.

These features help ApproLubes stand apart among oil lubricants distributors who may only focus on volume rather than value.

6. Tips for Selecting a Manufacturer‑Distributor Partnership

To pick the right fit when working with lube manufacturers, consider:

-

Visit or audit their plant if possible, or at least ask for photo/video evidence of blending, storage, and lab facilities.

-

Sample testing: request test batches; check them in real use.

-

Payment & credit terms: what margin, what payment cycle, what risks.

-

Contract details: exclusivity, territories, minimum order quantities, brand usage.

-

Support from manufacturer: marketing materials, product training, warranty support, technical documentation.

A healthy partnership allows both parties to grow, not just the manufacturer selling more oil.

7. Costs, Margins & Logistics Considerations

Understanding the cost and profit dynamics is crucial for oil lubricants distributors. Here’s a breakdown based on experience:

-

Cost components include cost of product from manufacturer, freight/transport, storage (warehousing, temperature control), packaging, handling losses, regulatory fees.

-

Margins vary: for standard lubricants, margins may be lower; for specialty, OEM or branded lubes, higher margins. Distributors often earn by volume plus value added services (training, technical support).

-

Logistics: mixing bulk transport (tankers for large orders) and packaged units (drums, pails) requires different handling capacity. Efficient inventory rotation is vital to avoid expiry or quality degradation.

-

Bulk vs small pack economics: Bulk reduces per unit cost, but small pack sales yield higher margin per litre, though handling and packaging costs increase.

Helpful Enhancements

-

Checklist for distributor due diligence when selecting lube manufacturers (certifications, lab results, lead times).

-

Glossary of lubrication terms (viscosity, base oil groups, API classifications, greases vs fluid lubricants).

-

Flowchart showing the supply chain: from raw base oil → manufacturing → distributor → end user.

-

Case Briefs: actual examples of failure when wrong lube was used vs success with correct one.

FAQ

Q1. What exactly is the role of oil lubricants distributors vs lube manufacturers?

Distributors act as the middle‑link: they buy from lube manufacturers, store, transport, and supply to workshops, factories, retail outlets. Manufacturers produce and in many cases refine or blend the oil, define specifications, conduct R&D. Distributors also provide value in logistics, customer support, and sometimes technical advice.

Q2. Can a distributor also act as a manufacturer?

Yes, some distributors blend their own formulations under license or contract blending. But that requires strict quality control, certification, and often greater investment. Separating roles ensures clarity and accountability.

Q3. What certifications or quality standards are essential?

Look for API (American Petroleum Institute), SAE viscosity classes, ISO certifications, OEM approvals, local environmental and safety certifications. These ensure product safety, performance, compliance.

Q4. How can distributors prevent counterfeit or adulterated lubricants in their supply chain?

Work only with certified lube manufacturers, verify seals and authenticity, monitor customer feedback, do periodic lab checks, ensure supply chain traceability, avoid suspicious discounts or sellers without trace.

Q5. What speciality lubricants offer higher margins?

Specialty lubes like high performance greases, synthetic engine oils, greases for extreme pressure (EP) conditions, transformer and turbine oils, food‑grade or pharma‑grade lubricants often carry higher margins. However, these require more stringent quality and handling.

- Questions and Answers

- Opinion

- Motivational and Inspiring Story

- Technology

- Live and Let live

- Focus

- Geopolitics

- Military-Arms/Equipment

- Sicurezza

- Economy

- Beasts of Nations

- Machine Tools-The “Mother Industry”

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film/Movie

- Fitness

- Food

- Giochi

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Altre informazioni

- Party

- Religion

- Shopping

- Sports

- Theater

- Health and Wellness

- News

- Culture