Can Africa Achieve Real Industrial Independence Without Investing in Machine Tools?

For decades, African leaders, economists, and development experts have envisioned a future where the continent is no longer a supplier of raw materials but a hub of industrial power.

Africa’s abundant resources, growing population, and youthful workforce provide the raw potential for such a transformation.

But one crucial question remains: Can Africa achieve real industrial independence without investing in machine tools?

The short answer is no. Without machine tools — the foundation of manufacturing — Africa’s industrial dreams risk remaining aspirational. The machine tool industry is often called the “mother of all industries” because it makes the machines that produce everything else. Without it, African economies cannot fully move up the value chain, cannot build sovereign industries, and cannot break free from dependence on imports.

This article explores why machine tools are indispensable for Africa’s industrial independence, what happens without them, and what a path forward might look like.

Why Machine Tools Matter for Industrial Independence

1. The Foundation of Manufacturing

Machine tools — such as lathes, milling machines, presses, grinders, and CNC systems — are used to cut, shape, and fabricate parts for all types of machinery. From tractors and turbines to cars and computers, every piece of equipment requires components that are produced with machine tools.

If Africa lacks its own machine tool industry, it must rely on imports to build factories, assemble products, and maintain equipment. This means industrial sovereignty is compromised at its very foundation.

2. The Multiplier Effect Across Sectors

Machine tools are not confined to a single industry; they power them all. Agriculture needs them to build processing plants, construction needs them for heavy equipment, energy needs them for turbines and pipelines, and healthcare requires them for surgical instruments and diagnostic machines.

Investing in machine tools doesn’t just build one sector — it builds all sectors. Without this multiplier effect, Africa risks stagnating in shallow industrial development.

3. The Innovation Platform

Machine tools are more than hardware. They represent precision, innovation, and advanced engineering. When countries design and produce their own machine tools, they foster a culture of technical mastery and innovation. Without this, African engineers may be trained to operate imported machines but rarely to design or innovate.

What Happens Without Machine Tools?

If Africa continues to industrialize without indigenous machine tool capacity, several structural problems persist:

1. Dependency on Imported Machinery

African industries today import nearly all of their equipment. For instance, textile mills rely on looms from China or India, while food processing plants use European machines. When these break down, spare parts must be shipped from abroad, creating costly delays and downtime.

This dependency keeps African industries vulnerable to supply chain disruptions, trade restrictions, and currency fluctuations.

2. Raw Material Trap

Africa’s wealth lies in natural resources: minerals, oil, cocoa, coffee, and timber. But without machine tools, the continent cannot easily process these resources into higher-value products.

-

Cocoa becomes chocolate abroad

-

Bauxite becomes aluminum elsewhere

-

Iron ore becomes steel overseas

Thus, Africa remains trapped in the low-value end of the global economy.

3. Skills Gap and Limited Industrial Ecosystem

Without machine tool production, Africa cannot fully develop the technical skills needed for industrial independence. Local universities and training centers may teach mechanical engineering, but without real toolmaking industries, graduates lack hands-on experience in precision manufacturing.

This prevents the growth of a self-sustaining ecosystem, where engineers, machinists, designers, and innovators collaborate to advance local industry.

4. Economic and Political Vulnerability

Countries that cannot make their own machines remain dependent on those that can. This dependence is not just economic but geopolitical. During crises, such as the COVID-19 pandemic, Africa was left behind in access to medical equipment partly because it lacked domestic manufacturing capabilities.

Lessons from Other Regions

History shows that no country has achieved industrial independence without machine tools.

-

Germany and Japan built global reputations in precision engineering because they invested heavily in machine tool innovation. Their automotive and electronics industries are direct beneficiaries.

-

China recognized in the 1980s that it could not rise without machine tools. By prioritizing machine tool industries, it became the world’s largest manufacturer and exporter.

-

India has developed domestic hubs for CNC machines and robotics, enabling “Make in India” manufacturing strategies.

These cases demonstrate a universal truth: industrial power rests on machine tool capacity. Africa cannot be an exception.

Can Africa Rely on Foreign Machine Tools Instead?

Some argue Africa does not need its own machine tool industries — it can import machines from established producers and focus on other sectors like agriculture or services. While imports may help in the short term, they create long-term dependency.

-

Costs: Importing tools drains foreign reserves and raises production costs.

-

Vulnerability: If geopolitical tensions disrupt supply, industries collapse.

-

Limited Growth: Import reliance discourages the development of local innovation, keeping Africa permanently behind.

Thus, relying on imports cannot deliver true independence. At best, it creates assembly economies that remain dependent on external supply chains.

What Would Investment in Machine Tools Achieve for Africa?

If Africa builds its own machine tool capacity, the results could be transformative:

-

Value Addition

-

Ghana could process cocoa into chocolate locally.

-

Guinea could turn bauxite into aluminum.

-

Nigeria could refine oil into petrochemicals.

-

-

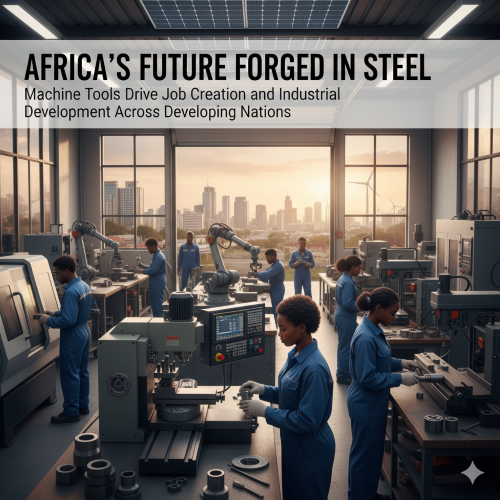

Job Creation

Skilled jobs in engineering, design, and machining would absorb Africa’s large youth population, reducing unemployment. -

Technology Leadership

Indigenous machine tool industries would push Africa into advanced fields such as robotics, CNC automation, and 3D printing. -

Economic Sovereignty

With domestic capacity, Africa could design its own industrial policies, free from dependency on foreign suppliers.

The Way Forward

Achieving real industrial independence will require a strategic and collective approach:

-

Regional Hubs: Africa does not need every country to build a full machine tool industry. Instead, regional centers (South Africa, Egypt, Nigeria, Kenya, Ethiopia) could specialize and serve wider markets.

-

Education and Training: Technical schools must emphasize tool design and machining, not just operation of imported systems.

-

Public–Private Partnerships: Governments should support startups, innovators, and joint ventures with foreign firms to build local toolmaking capacity.

-

Resource Integration: Africa’s mineral wealth should be harnessed for domestic steel, alloys, and precision materials.

-

Technology Leapfrogging: Africa can skip outdated paths and adopt modern CNC, AI-driven manufacturing, and additive technologies directly.

Conclusion

Industrial independence means more than having factories or assembly plants. It means having the capacity to build, repair, and innovate with the machines that sustain industries. Without investing in machine tools, Africa cannot break the cycle of raw material exports and import dependency.

Machine tools are not optional — they are the entry ticket into real industrial sovereignty. Just as no child can be born without a mother, no industrial future can be born without the “mother industry.” For Africa, the path to independence must begin with the machines that build all other machines.

The challenge is daunting, but the alternative — remaining forever dependent on others — is far costlier. Africa’s industrial future lies in its ability to build its own tools.

- Questions and Answers

- Opinion

- Motivational and Inspiring Story

- Technology

- Live and Let live

- Focus

- Geopolitics

- Military-Arms/Equipment

- Sicurezza

- Economy

- Beasts of Nations

- Machine Tools-The “Mother Industry”

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film/Movie

- Fitness

- Food

- Giochi

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Altre informazioni

- Party

- Religion

- Shopping

- Sports

- Theater

- Health and Wellness

- News

- Culture