Could investment in machine tools reduce Africa’s reliance on imported finished goods and save foreign exchange?

Africa has often been described as a continent rich in resources but poor in manufactured wealth.

Despite possessing abundant minerals, energy, and agricultural resources, African economies remain heavily dependent on imports of finished goods—from cars and industrial machinery to household appliances and medical equipment.

This dependence drains foreign exchange reserves, worsens trade deficits, and keeps Africa in a subordinate position within the global economy.

At the heart of this problem lies the absence of a strong machine tool industry. Machine tools—the lathes, milling machines, grinders, presses, and computer-controlled machining systems that produce parts for all other machines—are often called the “mother industry” because they enable the production of nearly every manufactured item.

Without them, Africa remains dependent on external suppliers for industrial goods.

The central question is: Can investment in machine tools help Africa reduce its reliance on imported finished goods and save foreign exchange? The answer is a resounding yes, and the reasons are manifold.

1. The Current Burden of Import Dependence

a. Importing Finished Goods at High Costs

Africa imports billions of dollars’ worth of finished goods every year. Automobiles, electronics, industrial equipment, and medical devices top the list. In 2022 alone, African countries spent over $63 billion on vehicle imports and tens of billions more on machinery and electronics. This pattern drains foreign currency reserves, often leading to balance-of-payment crises.

b. Weak Local Value Chains

Because African countries lack indigenous machine tool capacity, local industries are unable to produce essential machinery and spare parts. Even when African firms assemble products—such as cars in Nigeria or Ethiopia—they rely heavily on imported components. This undermines the development of robust local supply chains.

c. Foreign Exchange Pressures

Reliance on imports forces governments to allocate scarce foreign exchange for purchases abroad. When commodity prices fall, foreign exchange earnings shrink, making it harder for nations to pay for imports. This creates a cycle of dependency, currency depreciation, and inflation.

2. How Machine Tools Break the Cycle

a. Local Production of Industrial Goods

With machine tools, African nations can produce the parts and equipment needed for industries like automotive, construction, agriculture, and energy. Instead of importing tractors, solar panel frames, or steel fabrication equipment, countries can manufacture them locally.

For example:

-

Automotive sector: Instead of importing $5,000–$20,000 vehicles, African factories equipped with machine tools could produce them at lower cost using local labor and materials.

-

Agriculture: Instead of spending foreign exchange on tractors from Europe or Asia, Africa could manufacture them domestically, boosting food security and saving billions annually.

b. Reduced Import Bills

By manufacturing goods locally, Africa would reduce the massive outflow of foreign exchange used for finished imports. Even if not every product can be produced locally, replacing just 20–30% of finished imports with locally manufactured goods could save African economies tens of billions of dollars per year.

c. Creation of Domestic Value Chains

Machine tools enable local companies to produce spare parts, components, and specialized equipment. This supports domestic industries, reduces downtime from waiting on imports, and allows African economies to move up the global value chain.

3. Foreign Exchange Savings: Concrete Examples

a. Nigeria

Nigeria spends about $10 billion annually on vehicle imports. If local industries produced even 30% of vehicles and parts using machine tools, Nigeria could save $3 billion yearly. That money could be reinvested in infrastructure or education rather than leaving the country.

b. Kenya

Kenya imports most of its agricultural machinery. By producing irrigation pumps, plows, and tractors locally, the country could save hundreds of millions of dollars each year and support rural mechanization, doubling agricultural output.

c. South Africa and Egypt

Both nations already have some industrial base but remain dependent on high-tech imports. A stronger machine tool sector would allow them to reduce dependence on European and Asian suppliers, potentially saving $5–7 billion annually in foreign exchange.

d. Continental Scale

Across Africa, savings could reach $40–60 billion annually if domestic industries replaced even a modest share of imported finished goods with local production supported by machine tools.

4. Wider Economic Benefits Beyond Savings

a. Strengthening Local Currencies

By reducing the demand for foreign currency to pay for imports, African currencies would stabilize. This makes local economies more resilient to external shocks like oil price swings or global financial crises.

b. Industrial Learning and Technology Transfer

Machine tool industries force nations to master high-precision engineering, automation, and digital technologies. These skills spill over into other industries, creating a culture of innovation.

c. Export Potential

Once African firms master machine tools, they can export both machine tools themselves and finished goods. This shifts economies from being net importers to net exporters, earning foreign exchange rather than losing it.

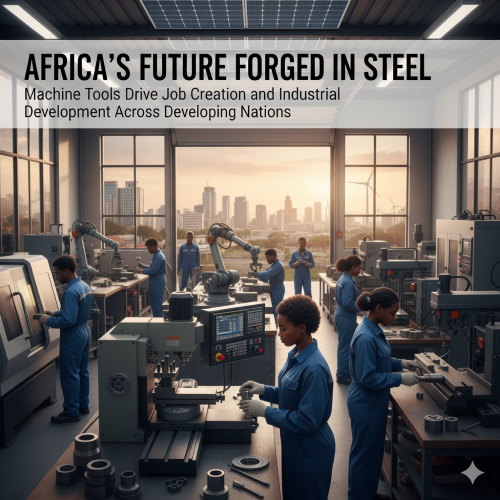

d. Job Creation and Incomes

As local industries expand, more jobs are created. Higher incomes mean more local spending, reducing the need for imported consumer goods and further saving foreign exchange.

5. Obstacles to Overcome

While the benefits are clear, building a machine tool industry is not without challenges.

-

High Capital Requirements – Machine tool factories require significant investment in equipment, precision technology, and skilled labor.

-

Skill Gaps – Africa must invest heavily in training engineers, machinists, and technicians to operate advanced equipment.

-

Infrastructure – Reliable electricity, transportation, and digital infrastructure are prerequisites for a thriving machine tool sector.

-

Policy Consistency – Governments must provide incentives for industrial investment, protect infant industries, and resist policies that favor raw material exports over local manufacturing.

6. The Way Forward

a. Regional Collaboration

Instead of each country trying to build a full spectrum of machine tool capacity, African nations could pool resources under the African Continental Free Trade Area (AfCFTA). For instance, one nation could specialize in agricultural machine tools, another in automotive, and another in energy.

b. Public–Private Partnerships

Governments should partner with private companies to build machine tool factories, offering tax incentives, subsidies, and infrastructure support.

c. Leveraging Diaspora and Global South Partnerships

Africa can learn from countries like India, Brazil, and China, which built machine tool industries despite starting from limited bases. Diaspora engineers and global south cooperation could accelerate skills transfer.

d. Building Technical Education

Technical universities and vocational schools must focus on precision engineering, CNC programming, robotics, and digital design to supply the human capital needed for machine tools.

Conclusion

Africa’s dependence on imported finished goods is one of the greatest barriers to true economic independence. Every container of vehicles, machinery, and electronics shipped into Africa represents not only a missed opportunity for local manufacturing but also a drain on foreign exchange reserves.

By investing in machine tools, African nations can begin to produce the machinery, vehicles, agricultural equipment, and renewable energy components they currently import.

This would drastically reduce import bills, save tens of billions of dollars annually in foreign exchange, strengthen local currencies, and lay the foundation for export-led growth.

"Machine tools are not just about factories and machines—they are about sovereignty, financial resilience, and industrial empowerment. If Africa embraces this path, it can transform from a continent that imports its future to one that manufactures it at home".

- Questions and Answers

- Opinion

- Motivational and Inspiring Story

- Technology

- Live and Let live

- Focus

- Geopolitics

- Military-Arms/Equipment

- Sécurité

- Economy/Economic

- Beasts of Nations

- Machine Tools-The “Mother Industry”

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film/Movie

- Fitness

- Food

- Jeux

- Gardening

- Health

- Domicile

- Literature

- Music

- Networking

- Autre

- Party

- Religion

- Shopping

- Sports

- Theater

- Health and Wellness

- News

- Culture