How can machine tool industries help develop technical and engineering skills among Africa’s youth?

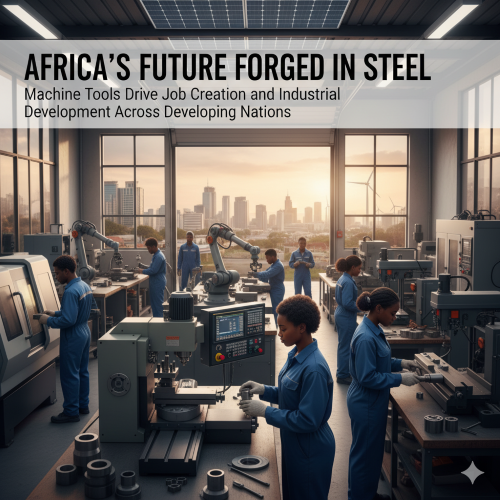

How Machine Tool Industries Can Help Develop Technical and Engineering Skills Among Africa’s Youth

Africa is often described as the world’s youngest continent. With nearly 60% of its population under the age of 25, the continent has an unprecedented opportunity to turn its youthful demographic into a powerful driver of industrialization and economic growth. Yet this potential faces a major obstacle: limited access to technical and engineering skills. Millions of young Africans leave school without practical training or pathways to industrial jobs.

One of the most effective ways to bridge this gap is through the development of machine tool industries—the foundation of modern manufacturing. Machine tools are the lathes, milling machines, presses, grinders, and CNC (computer numerical control) systems that produce parts for virtually every product in modern life, from automobiles to smartphones, tractors, wind turbines, and medical devices. They are often called the “mother of industries” because no manufacturing sector can exist without them.

For Africa’s youth, machine tool industries represent more than factories—they are schools of skills that can empower a generation with hands-on expertise, innovation capacity, and career opportunities.

1. The Skill Gap Challenge in Africa

a. Mismatch Between Education and Industry

Many African universities produce graduates in engineering and science, but curricula often emphasize theory over practice. Graduates may know the formulas behind thermodynamics or materials science, but they have never operated a lathe or designed a part for CNC production.

b. High Youth Unemployment

Despite the large number of young people entering the job market, formal employment opportunities are scarce. In many countries, youth unemployment hovers between 20–40%, with underemployment even higher.

c. Dependence on Imports

Because Africa lacks indigenous machine tool industries, it imports most finished goods and machinery. This means fewer opportunities for youth to gain experience in industrial environments where technical skills are developed.

2. How Machine Tool Industries Build Skills

a. Hands-On Training Grounds

Machine tool industries require machinists, welders, toolmakers, CAD/CAM (computer-aided design and manufacturing) programmers, and engineers. Young workers learn by doing—measuring, cutting, shaping, assembling, and troubleshooting parts. Unlike purely theoretical education, this kind of exposure builds competence and confidence.

b. Exposure to Advanced Technologies

Modern machine tool industries are no longer limited to manual equipment. They involve automation, robotics, AI-driven machining, and precision engineering. By working in such environments, young Africans gain cutting-edge skills directly relevant to Industry 4.0—the global shift toward smart manufacturing.

c. Cross-Disciplinary Learning

Machine tools sit at the intersection of multiple fields: mechanical engineering, materials science, electronics, software programming, and industrial design. This means young people exposed to the industry develop multi-disciplinary skills, making them versatile and competitive globally.

3. Pathways for Youth Skills Development Through Machine Tools

a. Vocational Training and Apprenticeships

Establishing machine tool factories and workshops creates the need for vocational schools aligned with industry. Young people can undergo apprenticeships where they work alongside experienced machinists, learning practical skills over 2–3 years. This is how Germany’s apprenticeship system helped it become a world leader in precision manufacturing.

b. University–Industry Partnerships

Machine tool industries can partner with universities to provide internships, industrial attachments, and R&D collaborations. Engineering students could spend semesters working on actual machining projects, designing components, or developing prototypes. This bridges the gap between classroom knowledge and industrial practice.

c. Youth Entrepreneurship in Manufacturing

By mastering machine tools, young entrepreneurs could establish small workshops producing spare parts, agricultural tools, or renewable energy components. For example, a group of trained machinists could set up a CNC workshop in Nairobi producing motorbike parts locally, reducing imports while creating jobs.

d. STEM Inspiration and Career Pathways

Machine tool industries can serve as inspiration for African youth interested in science, technology, engineering, and mathematics (STEM). Seeing tangible outputs—like tractors, drones, or turbines being made—motivates young people to pursue technical careers.

4. Sectoral Impacts on Youth Skills Development

a. Automotive Industry

Youth trained in machine tools can design and manufacture car parts, engines, and frames. This would support local automotive assembly plants and create opportunities for skilled employment in vehicle design and maintenance.

b. Agriculture

By producing plows, irrigation systems, and food processing machines, young machinists and engineers can directly impact food security. Training in machine tools empowers rural youth to innovate solutions tailored to local agricultural needs.

c. Renewable Energy

Wind turbine blades, solar panel frames, and hydropower components require precision machining. Involving youth in these industries not only builds technical skills but also aligns them with Africa’s green energy future.

d. Construction and Infrastructure

Machine tools make it possible to manufacture cranes, steel beams, and prefabricated housing components. Youth engaged in these industries would gain practical engineering experience that directly fuels Africa’s urbanization drive.

5. Long-Term Benefits for Youth and Nations

a. Job Creation and Employability

Machine tool industries directly employ thousands of machinists, engineers, and technicians. Indirectly, they enable millions of jobs in sectors like automotive, construction, and agriculture. Youth skilled in machine tools will find abundant opportunities across industries.

b. Innovation and Problem-Solving

By working with machine tools, young Africans can design and prototype solutions to local problems—whether it’s creating affordable farm tools, medical devices, or energy systems. This encourages innovation-driven economies rather than dependency.

c. Global Competitiveness

Youth trained in machine tool skills can compete in the global job market. Just as Indian IT workers became globally sought-after, African machinists, engineers, and CNC programmers could be in high demand if trained at scale.

d. Reduced Brain Drain

If machine tool industries provide challenging, well-paying jobs at home, fewer young Africans will feel compelled to migrate for opportunities abroad. Instead, their skills and energy remain invested in local economies.

6. Overcoming Barriers

For machine tool industries to truly transform youth skills, Africa must overcome several challenges:

-

Initial Capital Investment – Governments and private investors must commit to funding machine tool factories and training centers.

-

Curriculum Reform – Education systems must integrate practical machining and design into engineering and technical programs.

-

Mentorship and Expertise – Partnerships with countries like Germany, South Korea, and China could provide technical mentors until local expertise matures.

-

Policy Support – Governments should incentivize youth training in industrial skills through subsidies, scholarships, and public–private initiatives.

7. A Vision for the Future

Imagine an Africa where:

-

Technical schools in Lagos, Addis Ababa, and Johannesburg train thousands of machinists annually.

-

Universities in Nairobi and Accra have machine tool labs linked to local industries.

-

Young entrepreneurs in Kampala run CNC workshops producing affordable spare parts.

-

Renewable energy hubs in Morocco and Kenya employ youth trained to design turbine components.

In such a future, Africa’s youth are not job seekers but job creators, equipped with technical and engineering skills rooted in machine tool industries.

Machine tool industries are far more than factories—they are skill incubators for Africa’s youth. By developing these industries, Africa can bridge the gap between theoretical education and practical expertise, creating millions of skilled workers capable of driving industrialization, innovation, and self-reliance.

For a continent with the world’s youngest population, the return on investing in machine tools is generational. It is about more than machines; it is about building the engineers, innovators, and entrepreneurs who will shape Africa’s future.

If Africa is serious about unlocking the potential of its youth, the journey must start with the “mother industry”—machine tools.

- Questions and Answers

- Opinion

- Motivational and Inspiring Story

- Technology

- Live and Let live

- Focus

- Geopolitics

- Military-Arms/Equipment

- Sicurezza

- Economy

- Beasts of Nations

- Machine Tools-The “Mother Industry”

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film/Movie

- Fitness

- Food

- Giochi

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Altre informazioni

- Party

- Religion

- Shopping

- Sports

- Theater

- Health and Wellness

- News

- Culture