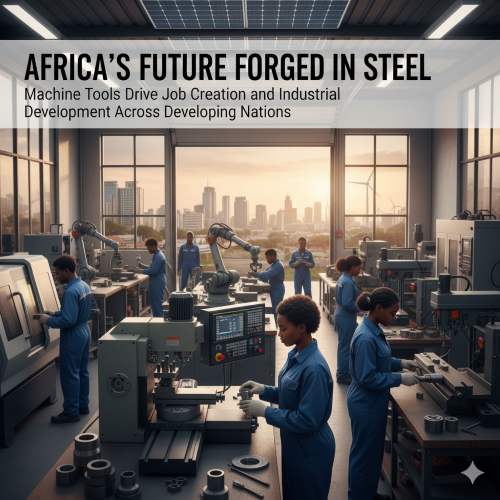

Could Building a Machine Tool Industry Also Strengthen Africa’s Defense, Healthcare, and Infrastructure Sectors?

Machine tools are the backbone of modern industrial economies. They are not just another sector of manufacturing but the foundational “industry of industries” that enables all others to exist and thrive.

A machine tool is essentially a device that makes other machines — from lathes and milling machines to computer numerical control (CNC) systems and 3D printers. Without them, local economies remain dependent on imported finished goods, unable to design, repair, or innovate independently.

For Africa, which is striving toward industrialization and greater sovereignty, investing in machine tools is not just about boosting productivity. It is about unlocking capacities that affect vital areas such as defense, healthcare, and infrastructure.

Let us explore how developing a machine tool industry in Africa could transform these critical sectors, create linkages across the economy, and position the continent for long-term self-reliance.

1. Defense and National Security

(a) Strategic Sovereignty

One of the biggest lessons of history is that no nation achieves real sovereignty without control over its defense industries. Africa currently imports the majority of its weapons, vehicles, and military hardware from external powers — often at high political and financial cost. A domestic machine tool industry would allow African states to begin manufacturing their own defense equipment, from basic components (nuts, bolts, casings) to more complex systems (drones, armored vehicles, naval parts).

For instance, South Africa’s defense industry in the 1980s (developed during the apartheid regime under sanctions) showed that African nations can build indigenous capabilities when forced to. However, without a broader machine tool base, many African states cannot maintain or upgrade imported weapons, leaving them perpetually dependent on foreign suppliers. A machine tool ecosystem would enable Africa to maintain, customize, and even innovate defense technologies suited to its geography and needs.

(b) Regional Security Integration

Africa faces diverse security challenges — terrorism in the Sahel, piracy in the Gulf of Guinea, insurgencies in the Horn of Africa. Machine tools can underpin regional defense collaboration by enabling cross-border production chains. For example, Nigeria, Ghana, and Côte d’Ivoire could jointly produce naval repair parts for Gulf of Guinea patrol vessels. East African states could pool resources for drone manufacturing. This would make African defense cooperation under the African Union more practical and less dependent on donor funding.

(c) Economic Spin-offs

Defense investments often spur civilian industry through spin-offs. Many technologies — GPS, the internet, composites — began as defense projects. By fostering machine tool capacity, Africa could stimulate broader innovations in precision engineering, cybersecurity, and robotics, which later feed back into civilian use.

2. Healthcare and Medical Technology

(a) Manufacturing Medical Equipment Locally

The COVID-19 pandemic highlighted Africa’s vulnerability to supply chain disruptions. Ventilators, PPE, and diagnostic machines had to be imported, often arriving too late. A machine tool industry would allow local firms to produce medical equipment on demand. Precision tools could fabricate ventilator parts, syringes, dialysis machines, and surgical instruments.

Countries like Kenya and Nigeria, which improvised local ventilators during COVID-19, proved that African engineers can innovate under pressure. What is missing is a robust machine tool base to mass-produce these prototypes and sustain supply beyond emergencies.

(b) Hospital Infrastructure and Maintenance

African hospitals frequently suffer from “equipment graveyards” — expensive MRI scanners or X-ray machines donated from abroad but left idle because spare parts are unavailable. With machine tool capacity, local workshops could fabricate replacement parts, extend the life of equipment, and reduce reliance on costly imports. This would save millions in healthcare budgets and ensure more consistent care delivery.

(c) Biotech and Pharmaceutical Industries

Precision machining is also essential for pharmaceutical production — from pill presses to packaging lines. With Africa’s growing pharmaceutical market (expected to exceed $60 billion by 2030), developing a domestic machine tool industry could strengthen medical self-sufficiency, ensuring African nations don’t depend solely on India or Europe for essential drug-making equipment.

3. Infrastructure and Industrial Development

(a) Building the Foundations

Infrastructure — roads, bridges, dams, railways, and power plants — requires heavy machinery, construction tools, and maintenance systems. Currently, much of this equipment is imported at high cost. A machine tool industry would enable Africa to produce construction machinery (excavators, cranes, road graders) domestically. This would not only reduce import bills but also create long-term local industries around spare parts, servicing, and upgrades.

(b) Energy and Renewable Power

Africa is pushing for energy independence through renewable sources like solar, wind, and hydro. Machine tools are crucial in fabricating turbines, solar panel mounts, gearboxes, and hydropower components. Instead of importing entire systems, African firms could produce and export renewable energy equipment. For instance, Ethiopia and Kenya, with abundant hydropower resources, could build turbine manufacturing capacity, while North African states could focus on solar equipment.

This would align with Africa’s climate goals while creating green jobs.

(c) Urbanization and Smart Cities

With Africa’s population expected to double by 2050, urban infrastructure will require constant expansion. A domestic machine tool sector would allow African cities to locally produce building materials, prefabricated housing systems, and transport equipment — reducing delays caused by foreign procurement. It would also make infrastructure projects more cost-effective and adapted to local needs.

4. Cross-Sectoral Benefits

(a) Youth Employment and Skills

Machine tool industries require highly skilled engineers, machinists, and designers. Establishing such industries would spur vocational training, apprenticeships, and technical education. Africa’s youth could be trained not only to operate imported machines but to design and build them, creating a generation of industrial innovators.

(b) Saving Foreign Exchange

Defense imports, medical imports, and infrastructure imports consume billions annually. Local machine tool industries would keep much of that spending inside African economies. Those savings could be redirected toward social investments in education and healthcare.

(c) Building Confidence in Local Production

A thriving machine tool industry would also help shift the mindset that “foreign is better.” When Africans see their own countries producing advanced technologies — from surgical instruments to drones — it builds pride and trust in local industries.

5. Challenges and Policy Recommendations

Of course, building a machine tool industry will not be easy. It requires huge capital investment, long-term planning, and strong state support. Key steps include:

-

Government Investment: States should prioritize machine tools in industrial policy, with subsidies, tax incentives, and R&D funding.

-

Regional Collaboration: The African Union and AfCFTA can coordinate efforts, avoiding duplication and building complementary hubs across the continent.

-

Technology Transfer: Partnerships with BRICS nations, especially China and India, could accelerate knowledge sharing.

-

Human Capital: Vocational centers, universities, and polytechnics must align curricula to precision engineering and mechatronics.

-

Defense-Industry Linkages: African defense budgets should allocate a percentage to local procurement, stimulating domestic machine tool demand.

Machine tools are not just about cutting metal; they are about shaping a nation’s future. For Africa, investing in machine tool industries could revolutionize three of its most critical sectors: defense, healthcare, and infrastructure. By giving the continent the ability to build, repair, and innovate independently, machine tools would enhance national security, save lives, and drive massive infrastructure growth.

If Africa wants true sovereignty and long-term development, it must recognize machine tools as the bedrock of modern industry. The dividends would not only be economic but also social and political, ensuring Africa is not just a consumer of other nations’ technologies but a producer of its own destiny.

- Questions and Answers

- Opinion

- Motivational and Inspiring Story

- Technology

- Live and Let live

- Focus

- Geopolitics

- Military-Arms/Equipment

- Segurança

- Economy

- Beasts of Nations

- Machine Tools-The “Mother Industry”

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film/Movie

- Fitness

- Food

- Jogos

- Gardening

- Health

- Início

- Literature

- Music

- Networking

- Outro

- Party

- Religion

- Shopping

- Sports

- Theater

- Health and Wellness

- News

- Culture