How does investing in machine tools contribute to Africa’s self-reliance and reduce vulnerability to global supply chain shocks (like during COVID-19)?

How Investing in Machine Tools Contributes to Africa’s Self-Reliance and Reduces Vulnerability to Global Supply Chain Shocks-

The COVID-19 pandemic exposed a truth many developing nations had long suspected: globalization is not an equal playing field. When borders closed, factories shut down, and global shipping faltered, Africa — heavily dependent on imported goods — found itself in a precarious position. Ventilators, masks, test kits, and even basic food and medical supplies became scarce or unaffordable. This crisis highlighted the dangers of depending on global supply chains controlled elsewhere.

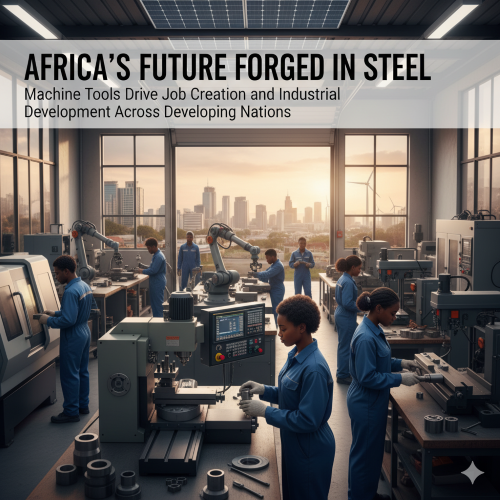

At the heart of this vulnerability lies Africa’s weak industrial base. Unlike Europe, Asia, or North America, the continent has not developed the “mother industry” of machine tools — the sector that produces the machines used to manufacture everything else. Investing in machine tools is, therefore, not just a matter of economic growth; it is central to achieving self-reliance and insulating Africa from global shocks.

1. Machine Tools as the Foundation of Self-Reliance

Machine tools are sometimes called “the machines that make machines.” They include lathes, milling machines, drills, grinders, and increasingly, computer numerical control (CNC) systems. Every modern product — from surgical instruments and tractors to smartphones and solar panels — depends on machine tools at some stage of its production. Without them, no country can maintain a resilient, independent manufacturing base.

For Africa, investment in this sector means creating the capacity to fabricate parts, repair imported machines, and eventually design new equipment suited to local conditions. Instead of waiting months for imported spares or paying inflated prices during global shortages, local industries could turn to domestic machine tool producers.

2. Lessons from COVID-19: Supply Chain Vulnerability

During the COVID-19 crisis, global supply chains were disrupted at multiple points:

-

Export restrictions: Countries like India banned exports of pharmaceuticals and medical equipment to prioritize domestic needs.

-

Shipping delays: Global container shortages and port closures meant goods from Asia or Europe took months to reach African shores.

-

Price spikes: With demand exceeding supply, the cost of PPE and ventilators skyrocketed, placing them out of reach for poorer nations.

-

Unequal access: Wealthy countries hoarded vaccines and equipment, leaving Africa at the back of the queue.

For Africa, this created a perfect storm of dependency. Countries with limited manufacturing capacity had no option but to wait or improvise. A domestic machine tool base would have changed the game: African nations could have scaled up local production of ventilators, oxygen tanks, masks, and hospital beds, reducing reliance on uncertain foreign supply lines.

3. How Machine Tools Strengthen Africa Against Global Shocks

(a) Enabling Local Production of Critical Goods

With a functioning machine tool industry, Africa could have produced much of its emergency medical equipment during the pandemic. For example, engineers in Kenya, Nigeria, and South Africa improvised ventilator prototypes, but mass production stalled because they lacked advanced machining capacity. Investment in machine tools ensures such prototypes can be scaled up rapidly in times of crisis.

(b) Building Flexibility and Adaptability

Supply chain resilience is about agility. A local machine tool industry gives Africa the flexibility to pivot production depending on demand. During peacetime, factories could manufacture agricultural equipment; during a crisis, the same facilities could switch to producing syringes, respirators, or food packaging machines. Such adaptability is impossible when relying solely on imports.

(c) Reducing Foreign Exchange Drain

Global crises often lead to currency depreciation and increased import costs. By producing more domestically, African nations can reduce foreign exchange outflows, stabilizing their economies during shocks. During COVID-19, billions of dollars were spent importing essential goods — money that could have supported local industries had machine tool capacity existed.

(d) Securing Maintenance and Repair Capabilities

During the pandemic, many African industries ground to a halt because they could not import spare parts for critical equipment. Machine tools make it possible to fabricate parts locally, ensuring continuous operation of hospitals, farms, and factories even when borders are closed.

4. Case Examples: What Could Have Been Different

(i) Medical Sector

South Africa imported most of its high-tech ventilators during COVID-19. Had there been machine tool capacity, it could have manufactured thousands of units domestically, not only meeting local demand but also exporting to neighbors like Zimbabwe and Mozambique.

(ii) Food Security

Lockdowns disrupted food imports, leaving many countries vulnerable. Local production of farm machinery, grain mills, and food processors would have stabilized domestic food chains. Ethiopia or Nigeria, for example, could have used machine tools to produce tractors and threshers, minimizing harvest losses.

(iii) Renewable Energy

Global shipping delays slowed solar and wind projects across Africa. Local machine tool factories could have fabricated mounting systems, turbines, and casings, keeping renewable energy expansion on track.

5. Broader Benefits for Long-Term Resilience

(a) Diversification of the Economy

By building machine tool industries, African economies would diversify beyond raw materials. This reduces vulnerability not just to pandemics, but also to commodity price crashes — another recurring global shock.

(b) Youth Employment and Skills

Investing in machine tools creates demand for machinists, engineers, and designers. Training Africa’s youth in these skills builds a workforce capable of responding to crises with innovation rather than dependence.

(c) Regional Integration

Machine tools lend themselves well to regional cooperation. Under the African Continental Free Trade Area (AfCFTA), different regions could specialize: East Africa in CNC machining, West Africa in agricultural equipment, North Africa in automotive tools. This would spread risk and build a continental buffer against global shocks.

6. Policy Pathways for Africa

To realize these benefits, governments must adopt deliberate strategies:

-

Industrial Policy Support: Subsidies, tax incentives, and protective tariffs for local machine tool manufacturers.

-

Public-Private Partnerships: Joint ventures between governments, local firms, and global technology providers.

-

R&D Investment: Funding universities and polytechnics to design locally appropriate machine tools.

-

Strategic Procurement: Governments should commit to sourcing medical and agricultural equipment from domestic producers when possible.

-

Regional Collaboration: Pooling resources to avoid duplication and achieve economies of scale under AfCFTA.

7. A Vision of African Self-Reliance

Imagine a future where, instead of scrambling for scarce imports during the next pandemic, African nations pivot seamlessly into local production. Hospitals are stocked with locally made ventilators and diagnostic machines; farms run on African-built tractors; renewable energy projects continue without interruption. This vision is only possible if Africa masters the art of making machines — that is, if it builds its own machine tool industry.

+++++++++++++++++++

COVID-19 was a wake-up call. It showed Africa the dangers of over-reliance on external supply chains and the need for self-reliance in essential industries. Investing in machine tools is the cornerstone of this shift. With local machine tool capacity, Africa can produce critical goods, maintain its industries, save foreign exchange, and respond flexibly to global disruptions. More than just a sector, machine tools are a strategic shield against future crises.

If Africa wants to stand strong in the face of pandemics, climate change, or geopolitical shocks, it must invest in the “mother industry” today. The next crisis is not a question of if, but when. The machine tool industry could be Africa’s best insurance policy.

By John Ikeji-Uju

- Questions and Answers

- Opinion

- Motivational and Inspiring Story

- Technology

- Live and Let live

- Focus

- Geopolitics

- Military-Arms/Equipment

- Sicurezza

- Economy

- Beasts of Nations

- Machine Tools-The “Mother Industry”

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film/Movie

- Fitness

- Food

- Giochi

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Altre informazioni

- Party

- Religion

- Shopping

- Sports

- Theater

- Health and Wellness

- News

- Culture