How Can Diaphragm Pressure Gauges Reduce Downtime in Industrial Plants?

Industrial operations rely heavily on accurate and reliable pressure measurement. In many applications, harsh conditions such as corrosive media, high viscosity fluids, or strong vibration can compromise standard gauges, leading to inaccurate readings or frequent failures. To address these challenges, engineers often use a diaphragm pressure gauge, a specialized instrument designed for precision and durability in demanding environments.

Understanding how diaphragm gauges contribute to operational efficiency helps industries reduce downtime, improve maintenance planning, and extend equipment lifespan. This article explores the design principles, functional advantages, and practical benefits of diaphragm pressure gauges in minimizing production interruptions and ensuring continuous plant performance.

Understanding the Diaphragm Pressure Gauge

Basic Principle of Operation

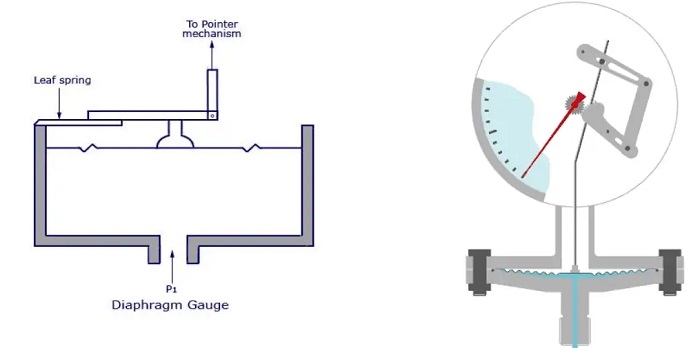

A diaphragm pressure gauge measures pressure through the deformation of a thin, flexible metal diaphragm. This diaphragm separates the process fluid from the gauge’s internal mechanism. When pressure is applied, the diaphragm deflects proportionally to the force exerted by the process medium. The movement is transmitted mechanically, usually through a linkage or filling fluid, to a pointer that displays the pressure on a dial.

The diaphragm element replaces the Bourdon tube commonly found in standard pressure gauges. Because the diaphragm is sensitive to minute pressure changes and resistant to contamination or clogging, it is ideal for measuring viscous, crystallizing, or corrosive fluids.

Common Applications in Industry

Diaphragm pressure gauges are widely used in industries such as chemical processing, food production, pharmaceuticals, wastewater treatment, and oil refining. These sectors often handle aggressive or particulate-laden fluids that could damage other pressure-sensing devices. The diaphragm design provides both protection and accuracy, ensuring reliable readings under extreme process conditions.

The Relationship Between Downtime and Pressure Measurement

The Cost of Instrument Failure

In industrial plants, equipment downtime is one of the most expensive operational setbacks. When pressure gauges fail or give inaccurate readings, the entire process may need to be stopped for inspection or repair. In continuous production environments, even a short interruption can lead to product losses, safety hazards, and high maintenance costs.

Standard gauges are prone to issues such as corrosion, clogging, or fatigue under high pressure or vibration. These failures often go unnoticed until they cause broader system malfunctions. By contrast, a diaphragm pressure gauge minimizes these risks through its robust and contamination-resistant design, helping operators maintain continuous operation.

The Role of Preventive Maintenance

Accurate pressure measurement supports preventive maintenance programs. When pressure readings remain consistent, maintenance teams can identify potential leaks, blockages, or pump inefficiencies before they escalate. Diaphragm gauges, due to their high stability and resistance to mechanical wear, reduce the frequency of instrument replacements and calibration interruptions.

This reliability directly translates to lower downtime, as fewer unscheduled stops are needed for sensor cleaning or replacement.

Design Features That Support Continuous Operation

Isolation of Process Media

A key feature of the diaphragm pressure gauge is its ability to isolate the process medium from the sensing mechanism. The diaphragm forms a barrier between the internal components and the fluid, often filled with a protective system fluid like silicone oil or glycerin.

This isolation prevents the gauge from being exposed to corrosive or clogging substances. For example, in the chemical industry, certain acids or alkalis could destroy conventional gauge materials within weeks. The diaphragm, often made from stainless steel, Hastelloy, or Tantalum, resists these effects, allowing continuous monitoring without risk of contamination or failure.

Compatibility with Hygienic Processes

In industries such as pharmaceuticals or food and beverage production, hygiene is paramount. The diaphragm pressure gauge is specifically designed to meet sanitary requirements, featuring smooth surfaces and crevice-free connections that prevent bacterial accumulation.

Because it can be cleaned in place without disassembly, it reduces the time needed for maintenance shutdowns. This characteristic not only protects product integrity but also supports efficient cleaning cycles and faster return to operation.

Protection from Vibration and Pulsation

Industrial pumps and compressors often create vibrations or pulsating pressures that can wear down sensitive instruments. To counteract this, many diaphragm gauges incorporate damping fluids or mechanical dampers that absorb these shocks.

This design ensures stable readings even in dynamic flow conditions. Stable measurements help operators maintain precise control over system parameters, preventing operational fluctuations that might otherwise trigger emergency stops or mechanical stress.

Calibration Stability and Accuracy

Reduced Need for Recalibration

Unlike conventional gauges that experience drift over time, a diaphragm pressure gauge maintains calibration stability due to its simple mechanical structure and minimal moving parts. The diaphragm’s elastic properties allow it to return to its original shape after each pressure cycle, ensuring consistent performance.

As a result, recalibration intervals can be extended, reducing the frequency of maintenance tasks. Fewer recalibration sessions mean less downtime, particularly in systems where each shutdown requires careful pressure isolation and requalification.

Accuracy in Harsh Conditions

Many pressure sensors lose accuracy when exposed to temperature extremes, vibrations, or media buildup. The diaphragm design, however, remains stable even in these environments. Whether installed in hot process lines or cold storage systems, it provides dependable measurements that support safe and efficient operation.

This high level of accuracy prevents false alarms and unnecessary shutdowns caused by incorrect pressure readings, which are common in sensitive industrial systems.

Adaptability Across Different Process Conditions

Customization for Media and Pressure Ranges

One advantage of the diaphragm pressure gauge is its adaptability to diverse applications. Manufacturers offer variations in diaphragm materials, fill fluids, and mounting configurations to match specific industrial conditions.

For instance, gauges designed for high-pressure steam systems use reinforced diaphragms, while those for vacuum or ultra-low pressure applications feature thin, highly sensitive membranes. This customization ensures that each installation achieves maximum reliability, reducing the risk of measurement failure that could lead to unplanned downtime.

Resistance to Process Contamination

In some industrial environments, fluid impurities can block pressure ports or cause sediment buildup in sensors. The wide, open design of diaphragm seals minimizes these risks. Since there are no narrow passages for material accumulation, the gauge remains functional even when exposed to slurry, paste, or other thick substances.

This resistance to clogging ensures uninterrupted operation, especially in wastewater treatment or petrochemical systems where particulate matter is common.

Integration with Modern Monitoring Systems

Digital Compatibility

Modern diaphragm pressure gauges can be integrated into automated monitoring networks. Many models now include electrical transmitters that convert mechanical deflection into electronic signals. These outputs allow remote data collection and continuous system tracking.

With real-time monitoring, maintenance teams can detect abnormal pressure variations before they cause system failure. This proactive approach enables predictive maintenance, reducing emergency shutdowns and extending operational uptime.

Smart Diagnostics

Advanced diaphragm gauges equipped with sensors and communication interfaces can self-diagnose performance deviations. These diagnostics notify operators when calibration or cleaning is required. Instead of relying on fixed maintenance schedules, technicians can service the instrument only when necessary, minimizing downtime while maintaining reliability.

Economic and Operational Benefits

Long-Term Cost Efficiency

Although a diaphragm pressure gauge may have a higher initial cost than standard gauges, its long-term benefits far outweigh the investment. Reduced maintenance frequency, fewer replacements, and stable calibration lead to lower operational costs over the life of the equipment.

When combined with automation systems, diaphragm gauges contribute to data-driven maintenance, further improving cost efficiency and productivity.

Enhanced Safety and Compliance

Accurate pressure measurement directly supports plant safety. By preventing overpressure conditions, leaks, and equipment strain, diaphragm gauges reduce the likelihood of accidents and costly system failures. Furthermore, their compliance with industry standards ensures that operations remain within regulatory safety margins, avoiding penalties or production delays.

Conclusion

The diaphragm pressure gauge represents a vital innovation in industrial measurement technology. Through its robust construction, isolation of process media, and compatibility with harsh or sanitary conditions, it minimizes the factors that typically cause downtime in industrial plants.

By providing stable, accurate, and maintenance-friendly performance, diaphragm gauges allow continuous monitoring of critical systems, reducing the need for shutdowns and manual intervention. Their adaptability across industries—from chemical processing to food production—makes them indispensable in modern industrial operations.

Ultimately, the ability of diaphragm gauges to resist corrosion, vibration, and contamination ensures uninterrupted process control. When integrated with modern monitoring systems, they become central to predictive maintenance strategies, safeguarding productivity and operational continuity.

For industries focused on efficiency and reliability, adopting diaphragm pressure gauges is not merely a technical upgrade but a strategic investment in reducing downtime and optimizing plant performance.

- Questions and Answers

- Opinion

- Motivational and Inspiring Story

- Technology

- Live and Let live

- Focus

- Geopolitics

- Military-Arms/Equipment

- Securitate

- Economy

- Beasts of Nations

- Machine Tools-The “Mother Industry”

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film/Movie

- Fitness

- Food

- Jocuri

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Alte

- Party

- Religion

- Shopping

- Sports

- Theater

- Health and Wellness

- News

- Culture