What role can 3D printing, robotics, and digital manufacturing play in Africa’s machine tool development?

The Role of 3D Printing, Robotics, and Digital Manufacturing in Africa’s Machine Tool Development-

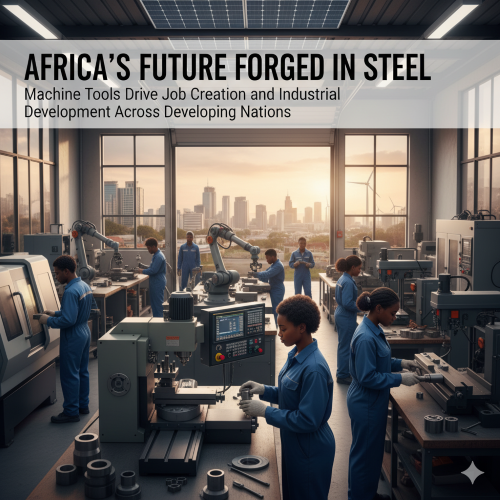

Africa stands at a historic industrial crossroads. The continent’s growing youth population, expanding consumer base, and the rise of the African Continental Free Trade Area (AfCFTA) present immense opportunities for industrial growth.

Yet, Africa’s dependence on imported machinery and tools remains one of the biggest obstacles to local manufacturing. Machine tools — the foundational equipment for producing all other machines — remain scarce, costly, and mostly imported.

In this context, emerging technologies such as 3D printing (additive manufacturing), robotics, and digital manufacturing represent transformative tools that can bridge Africa’s industrial gap. They enable cost-effective local production, rapid prototyping, and scalable innovation — all essential for building a domestic machine tool industry.

This article explores how these technologies can accelerate Africa’s journey toward machine tool self-reliance, industrial diversification, and economic resilience.

1. The Technological Revolution: A Chance to Leapfrog

Historically, Africa missed the first and second industrial revolutions that shaped Western and Asian manufacturing powerhouses. However, the Fourth Industrial Revolution (4IR) — driven by digitalization, automation, and smart technologies — offers a unique opportunity for Africa to leapfrog traditional industrial pathways.

In conventional manufacturing, setting up a machine tool factory requires massive capital investments, precision foundries, and decades of experience. But with digital tools like 3D printers, CNC routers, and robotic automation, African innovators can build, test, and refine prototypes at a fraction of the historical cost.

The same digital design principles used by global machine tool leaders such as Siemens, Haas, and DMG Mori can now be learned and replicated using open-source platforms and low-cost fabrication equipment.

This democratization of manufacturing technology is Africa’s gateway to industrial independence.

2. 3D Printing: The New Frontier of Localized Manufacturing

a. From Prototyping to Production

3D printing, or additive manufacturing, allows designers to produce complex metal and plastic parts layer by layer directly from digital designs. For Africa’s emerging machine tool ecosystem, this is revolutionary.

Start-ups, universities, and local workshops can now design and print:

-

Replacement parts for broken machines.

-

Custom jigs, fixtures, and molds for small-scale production.

-

Precision components like gears, brackets, and casings.

-

Prototype models for new machine tool concepts.

For example, a small engineering team in Ghana can design a lathe part using CAD software, 3D print it for testing, and then refine the design before mass-producing it in metal using CNC machines.

b. Reducing Dependence on Imports

Instead of waiting months to import parts from Europe or China, local industries can print critical components within days. This not only saves time and money but also builds local technical expertise.

c. Affordable Access

The cost of 3D printers has dropped dramatically. Entry-level desktop models are available for under $500, while advanced metal printers are increasingly being localized. African tech hubs like Gearbox (Kenya), iHub (Nigeria), and MakersLab (South Africa) already use 3D printing for local innovation — a trend that can expand into full-scale tool-making.

d. Training and Education

3D printing also provides a hands-on learning tool for students and apprentices. They can visualize mechanical designs, test tolerances, and understand how parts interact — all essential skills for machine tool engineering.

3. Robotics: Automating Precision and Productivity

Robotics is another pillar of modern machine tool development. Robots enhance precision, consistency, and speed in machining, welding, and assembly.

a. Industrial Automation for Machine Tool Factories

Even small-scale machine tool workshops can integrate robotic arms for repetitive or precision tasks — such as drilling, polishing, or loading parts into CNC machines. These robots can operate continuously, improving efficiency and output quality.

b. Low-Cost, Locally Built Robots

African innovators are already designing affordable, open-source robotic systems using locally available materials and electronics. By linking robotics with 3D printing and local programming skills, African machine tool startups can create cost-effective automation solutions.

For example:

-

In Uganda, local engineers have built simple robotic arms for packaging and assembly.

-

In South Africa, researchers are experimenting with robotic welders for small-scale manufacturing.

-

Nigerian tech hubs are exploring Arduino-based robotics for CNC automation.

c. Robotics for Vocational Training

Robotics programs can transform technical education by giving students exposure to automation, control systems, and mechatronics — critical disciplines for modern machine tool industries.

d. AI Integration

By integrating artificial intelligence (AI) and machine learning, robotic systems can self-optimize tool paths, detect defects, and predict maintenance needs — drastically improving performance and reducing costs over time.

4. Digital Manufacturing: The Backbone of Smart Industry

Digital manufacturing connects every step of production — from design and simulation to machining and quality control — through data and software integration.

a. Computer-Aided Design and Manufacturing (CAD/CAM)

Software like SolidWorks, Fusion 360, and FreeCAD enables African engineers to design and simulate machine components before physical production. Once designs are ready, they can be exported directly to CNC machines or 3D printers.

b. Digital Twins and Simulation

A “digital twin” is a virtual replica of a machine or production line that allows engineers to test performance, optimize processes, and prevent errors. Even African SMEs can use free or low-cost versions of such software to improve manufacturing accuracy.

c. Cloud-Based Collaboration

Digital platforms allow African innovators to collaborate across borders, sharing blueprints, software code, and design improvements. This can foster regional co-development under AfCFTA — for example, an engineer in Ethiopia could design a machine head while a partner in Kenya fabricates the housing.

d. Smart Factories and Data Analytics

As Africa’s industries grow, smart factories — integrating sensors, data analytics, and IoT (Internet of Things) — can monitor performance in real time, reducing downtime and optimizing energy use. This digital infrastructure will form the core of Africa’s future machine tool clusters.

5. Economic and Strategic Benefits

Integrating 3D printing, robotics, and digital manufacturing in Africa’s machine tool development brings multiple economic and strategic gains:

-

Cost Reduction – Local production drastically cuts import costs and shipping delays.

-

Job Creation – New skills in design, programming, and digital fabrication generate high-quality jobs for youth.

-

Resilience – During crises like COVID-19, local digital manufacturing networks can produce essential equipment without global dependence.

-

Export Potential – Africa can become a competitive exporter of small-scale, affordable machine tools and spare parts to other developing regions.

-

Innovation Ecosystem – The combination of digital design, fabrication labs, and entrepreneurship will nurture Africa’s next generation of industrial leaders.

6. Challenges and Solutions

While the potential is vast, several challenges must be addressed:

-

High Initial Costs: Governments and development banks should create equipment leasing programs or shared fabrication centers for small businesses.

-

Skills Gap: Universities and polytechnics must integrate digital manufacturing, robotics, and 3D design into their curricula.

-

Infrastructure Deficiencies: Reliable power and internet connectivity are essential for digital factories; governments must prioritize industrial zones with dedicated utilities.

-

Standardization: Regional standards bodies should establish quality benchmarks for locally produced machine tools to ensure safety and reliability.

-

Financing Innovation: Development banks and sovereign funds should support machine tool technology incubators and offer R&D grants to innovators.

7. Case Study Snapshots

-

South Africa: The Centre for Rapid Prototyping and Manufacturing at Central University of Technology produces 3D-printed components for industry and healthcare.

-

Kenya: Gearbox provides local engineers access to digital fabrication tools and mentorship for machine design.

-

Nigeria: Makerspace Lagos teaches young engineers to use 3D printing and robotics for manufacturing solutions.

-

Egypt: The Smart Manufacturing Initiative promotes industrial digitalization with state support for robotics integration.

These examples demonstrate that the foundation already exists — it only needs scaling and coordination.

8. The Road Ahead: A Digital Industrial Africa

To fully leverage 3D printing, robotics, and digital manufacturing in machine tool development, African governments should pursue:

-

National 4IR strategies focused on manufacturing.

-

Regional centers of excellence for digital fabrication.

-

Pan-African open innovation platforms where machine tool blueprints are shared freely.

-

Partnerships with countries like India, Germany, and China for technical training and equipment transfer.

-

Incentives for private sector and start-up participation in smart manufacturing.

3D printing, robotics, and digital manufacturing are not luxuries — they are strategic tools for Africa’s industrial liberation. They make it possible for small innovators, students, and engineers to build what once required massive factories and foreign capital.

By embracing these technologies, Africa can transform its manufacturing base, empower its youth, and establish the machine tool industry that forms the heart of modern civilization. The path to a self-reliant, technologically advanced Africa begins not in foreign imports — but in local digital workshops where innovation meets precision.

- Questions and Answers

- Opinion

- Motivational and Inspiring Story

- Technology

- Live and Let live

- Focus

- Geopolitics

- Military-Arms/Equipment

- Sicherheit

- Economy

- Beasts of Nations

- Machine Tools-The “Mother Industry”

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film/Movie

- Fitness

- Food

- Spiele

- Gardening

- Health

- Startseite

- Literature

- Music

- Networking

- Andere

- Party

- Religion

- Shopping

- Sports

- Theater

- Health and Wellness

- News

- Culture