Should Africa leapfrog into CNC (computer numerical control) and automated systems instead of focusing on old manual tools?

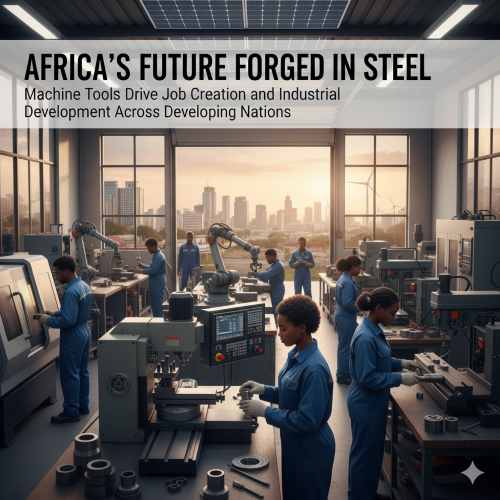

Africa stands at a defining moment in its industrial journey. For decades, the continent’s manufacturing sector has been limited by dependence on imported machinery, lack of technical capacity, and underdeveloped machine tool industries. The result has been a continued reliance on exporting raw materials instead of producing finished goods. But today, a new opportunity has emerged — the rise of Computer Numerical Control (CNC) and automated manufacturing systems, which have revolutionized industrial production globally.

The central question is: Should Africa invest in modern CNC and automated technologies, leapfrogging traditional manual machines, or first master the basics of manual machine tools?

This question is not merely about technology; it’s about strategy, timing, and vision. It touches on how Africa envisions its industrial identity — as a latecomer struggling to catch up or as a bold innovator ready to embrace the digital future.

1. Understanding the Difference: Manual vs. CNC Systems

Before answering whether Africa should leapfrog, it’s important to clarify the distinction between manual machine tools and CNC (Computer Numerical Control) systems.

-

Manual machines — such as lathes, milling machines, and drills — are operated by skilled machinists using hand controls. These machines are affordable and ideal for teaching basic mechanical principles, repair work, and low-volume production. However, they rely heavily on human precision and labor time.

-

CNC machines, on the other hand, are computer-controlled. They use programmed instructions (often in G-code) to perform precise, repeatable machining operations automatically. CNC systems can produce complex shapes, multiple identical parts, and operate 24/7 with minimal human error.

Automation — which combines CNC with robotics, sensors, and data analytics — represents the next level of industrial efficiency, allowing “smart factories” to optimize production in real time.

2. The Case for Leapfrogging: Why CNC May Be Africa’s Best Bet

Africa missed much of the 20th century’s heavy industrialization wave. However, this late entry offers a hidden advantage — the ability to bypass obsolete technologies and go directly to more efficient, digital, and scalable methods.

a. The Leapfrog Advantage

Just as Africa leapfrogged from limited landline infrastructure to widespread mobile phone adoption, it can apply the same model to manufacturing. Instead of spending decades building industries around outdated manual tools, Africa can start with digital-first systems that are compatible with 21st-century global supply chains.

For example:

-

A CNC milling machine connected to CAD/CAM software can produce precision components that meet global export standards.

-

Automation can allow African factories to compete with Asian manufacturers on quality and speed, not just cost.

b. Addressing the Skills Gap

While critics argue that Africa should first master manual machining, it’s worth noting that CNC systems are actually easier to learn for digital-native youth. Today’s students are already comfortable with computers, coding, and digital interfaces — skills that directly translate into CNC programming.

By teaching CNC and automation alongside foundational mechanics, Africa can create a generation of hybrid engineers who understand both traditional and digital manufacturing methods.

c. Higher Productivity and Precision

CNC machines can perform in hours what manual tools may take days to accomplish — and with greater accuracy. For Africa’s growing industries (automotive, aerospace, construction, energy), precision and scalability are critical. CNC-based systems would enable mass production of quality components, boosting both domestic manufacturing and export competitiveness.

d. Global Supply Chain Integration

Modern industries operate on digital manufacturing networks, where parts are designed in one country and produced in another using shared CAD files. Africa cannot fully participate in such networks using outdated manual tools. Leapfrogging into CNC ensures interoperability with global digital production systems — a crucial step for industrial independence.

3. Economic and Strategic Benefits of Going CNC-First

a. Attracting Foreign Direct Investment (FDI)

Investors are drawn to regions with modern, efficient manufacturing ecosystems. Establishing CNC-based facilities demonstrates technological readiness, making African nations more attractive for joint ventures, subcontracting, and industrial parks.

b. Creating High-Value Jobs

CNC and automation do not eliminate jobs — they transform them. Instead of repetitive manual labor, workers become operators, programmers, and maintenance technicians, earning higher wages and gaining transferable technical expertise.

c. Building Industrial Ecosystems

CNC-driven industries can catalyze other sectors — such as tool-making, robotics, electronics, and software engineering. These interconnected industries are the foundation of self-sustaining industrial economies like Germany, Japan, and South Korea.

d. Reducing Waste and Increasing Sustainability

Automation enables precise material usage, minimizing waste and improving energy efficiency — vital for Africa’s sustainability goals. CNC systems can also be integrated with renewable energy-powered manufacturing, reducing dependence on fossil fuels.

4. Challenges and Risks of Leapfrogging

Leapfrogging into CNC and automation is not without obstacles. African countries must consider the following challenges carefully:

a. High Capital Costs

CNC machines and automation systems are significantly more expensive than manual tools. A single CNC lathe can cost anywhere from $30,000 to over $200,000. However, this can be mitigated through:

-

Public-private partnerships (PPPs) for shared factory equipment.

-

Regional machine tool hubs under AfCFTA.

-

Leasing programs to make CNC equipment accessible to SMEs.

b. Inadequate Power and Internet Infrastructure

CNC and automated systems rely on stable electricity and connectivity for programming, maintenance, and monitoring. Governments must prioritize reliable power supply and broadband infrastructure in industrial zones.

c. Lack of Local Technical Support

Without trained technicians and engineers, CNC machines can fall into disrepair. This highlights the need for strong vocational training programs and industry-academia partnerships to build local capacity for maintenance, software programming, and repair.

d. Risk of Technological Dependence

Importing CNC machines without local production capacity can perpetuate dependency on foreign suppliers for spare parts and software updates. To avoid this, Africa should encourage local assembly, software customization, and eventually indigenous CNC production.

5. The Balanced Approach: Integrating Old and New

While the leapfrog model offers exciting potential, a balanced strategy may work best. Manual machines should not be completely abandoned — they remain valuable for:

-

Foundational training in mechanics and precision.

-

Rural workshops where power or connectivity may be limited.

-

Repair and maintenance work for older equipment.

Therefore, Africa’s industrial plan should follow a dual-track approach:

-

Use manual tools for training and basic production.

-

Rapidly scale up CNC and automation for advanced manufacturing and export-oriented industries.

This mirrors the model of India’s industrial development, where both manual and CNC systems coexist, serving different market segments.

6. The Role of Education and Policy

a. Vocational and University Training

Polytechnics and technical universities must introduce CNC programming, mechatronics, and automation engineering as core disciplines. Apprenticeships should combine hands-on work with digital design and coding.

b. Government Incentives

Governments can accelerate CNC adoption by:

-

Offering tax incentives for factories investing in CNC equipment.

-

Funding CNC training centers and fabrication labs.

-

Creating industrial clusters with shared automation infrastructure.

c. Local Innovation

African engineers can develop low-cost CNC solutions using open-source hardware (like Arduino or Raspberry Pi). Such innovations can drastically lower barriers for small and medium manufacturers.

7. Examples and Emerging Models

Several African initiatives are already embracing CNC and automation:

-

Gearbox Kenya teaches CNC programming and supports start-ups in digital manufacturing.

-

South Africa’s CSIR (Council for Scientific and Industrial Research) develops automated systems for local industries.

-

Egypt’s Smart Manufacturing Initiative integrates CNC and robotics into national industrial policy.

-

Nigeria’s makerspaces are experimenting with locally assembled CNC routers for wood and metal fabrication.

These early efforts prove that Africa can adopt CNC technologies pragmatically and progressively.

The Case for a CNC-Driven Future

Africa’s future in manufacturing depends not on imitating the past but on innovating for the future. Manual tools can still play a supporting role, but the real leap toward industrial independence will come through embracing CNC and automation.

CNC systems represent more than machines — they embody precision, repeatability, digital integration, and global competitiveness. If Africa aims to build cars, turbines, medical devices, or agricultural machinery locally, CNC mastery is essential.

By strategically leapfrogging outdated industrial models, Africa can compress decades of technological evolution into years — creating a new generation of digitally skilled engineers, globally competitive manufacturers, and truly sovereign economies.

The choice is clear: Africa’s industrial destiny lies not in turning the old manual handles of the past, but in programming the digital codes of the future.

- Questions and Answers

- Opinion

- Motivational and Inspiring Story

- Technology

- Live and Let live

- Focus

- Geopolitics

- Military-Arms/Equipment

- Sécurité

- Economy

- Beasts of Nations

- Machine Tools-The “Mother Industry”

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film/Movie

- Fitness

- Food

- Jeux

- Gardening

- Health

- Domicile

- Literature

- Music

- Networking

- Autre

- Party

- Religion

- Shopping

- Sports

- Theater

- Health and Wellness

- News

- Culture