What Risks Do African Countries Face if They Continue to Depend on Foreign Machine Tool Imports Indefinitely?

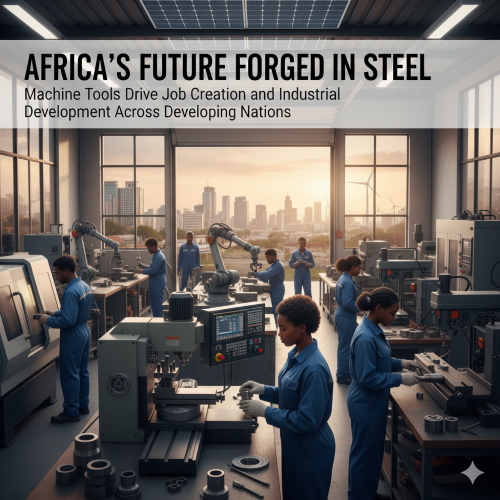

In every industrialized nation, the foundation of modern manufacturing lies in one essential capability — the ability to produce and maintain machine tools.

These are the “mother machines” that build everything else: vehicles, turbines, medical equipment, construction machinery, electronics, and even defense systems.

Without them, a country’s factories cannot operate independently, its industries remain fragile, and its sovereignty is compromised.

For Africa, a continent striving for industrialization, job creation, and technological independence, the continued reliance on imported machine tools represents a silent but significant threat.

While importing tools may seem convenient in the short term, the long-term consequences are far more serious — spanning economics, security, education, and political autonomy.

If Africa does not develop its own machine tool industry, it risks remaining trapped in a cycle of dependency and underdevelopment.

1. The Foundation of Industrial Dependency

Machine tools are the most strategic layer of industrial capability because they enable a country to build and repair all other machines. They cut, shape, and assemble parts for everything from aircraft and tractors to hospital scanners and power generators.

When African nations depend entirely on imported machine tools, they lose control over the very basis of industrial production. Factories may appear busy assembling vehicles or electronics, but the core technology — the tools that make those machines — belong to foreign suppliers. This situation means that any disruption in global trade, sanctions, or currency fluctuations can instantly paralyze production.

In essence, Africa becomes an industrial tenant rather than an owner — renting technology, tools, and expertise without building local capacity.

2. Economic Risks: Trade Imbalance and Capital Flight

The economic consequences of permanent dependency on imported machine tools are enormous.

a) Perpetual Trade Deficits

Machine tools are high-value imports. Every shipment drains foreign currency reserves. Over decades, this results in persistent trade deficits and weak currency stability. Instead of using domestic capital to build industries, African nations continuously send wealth abroad to buy tools and spare parts.

For example, if a country like Nigeria or Kenya spends billions importing industrial equipment annually, those funds could have been reinvested into local manufacturing and research.

b) Capital Flight and Debt

Because machine tools are expensive, many African nations finance their imports through loans or foreign investment. This increases debt dependency on donor nations and financial institutions like the IMF or World Bank, perpetuating economic vulnerability.

c) Stunted Local Manufacturing

Without domestic machine tool production, local entrepreneurs struggle to establish factories. They must import not only production machines but also replacement parts and technical expertise. This raises operating costs and limits competitiveness. As a result, Africa remains an exporter of raw materials and an importer of finished goods — the very structure that colonial powers established centuries ago.

3. Industrial Risks: Fragile Supply Chains and Slow Innovation

a) Supply Chain Vulnerability

Dependence on foreign machine tools means that even a minor disruption in international logistics can halt African production. During the COVID-19 pandemic, many African industries faced months-long delays in obtaining critical machinery or spare parts. Similar disruptions occurred during the Russia–Ukraine war, affecting global steel and precision part supplies.

A continent that cannot manufacture its own tools is at the mercy of events beyond its borders — a dangerous position for any developing region.

b) Slow Technological Innovation

Machine tool industries are the heart of technological innovation. They drive advancements in robotics, precision engineering, and artificial intelligence in manufacturing. Without them, Africa’s capacity to innovate remains stunted. Universities may teach engineering, but without a domestic tool industry, students lack real-world experience in design, machining, and automation.

This leads to a disconnect between education and industry — producing graduates who must emigrate to apply their skills, further worsening the brain drain.

4. Employment and Skills Erosion

Machine tool industries are major employers in industrialized economies. They create high-skill jobs in design, machining, metallurgy, automation, and maintenance.

By continuing to import machine tools indefinitely, Africa effectively outsources its most valuable jobs — not just assembly-line work, but engineering and innovation roles. Each imported tool represents lost employment opportunities for African youth who could have been trained as machinists, toolmakers, or design engineers.

This has long-term social consequences:

-

High youth unemployment.

-

Reduced innovation culture.

-

Loss of confidence in local technical education.

Over time, the absence of domestic industry leads to an erosion of technical expertise, making Africa even more dependent on foreign engineers for maintenance and production.

5. Strategic and Security Risks

Industrial dependency is not just an economic issue — it is a matter of national security. When a country cannot produce or repair its own industrial equipment, it becomes vulnerable to political pressure and manipulation.

a) Sanctions and Political Leverage

Foreign powers can easily influence nations that depend on their machine tools. If an African country adopts policies that conflict with the interests of a major supplier, it risks being cut off from critical machinery or spare parts. This has happened repeatedly in history — from Iran and Venezuela under sanctions to smaller African nations during political disagreements.

Without local capacity, sanctions can cripple not just military equipment, but food processing, energy, and transportation systems — effectively paralyzing the nation.

b) Defense Vulnerability

Modern defense systems — aircraft, tanks, missiles, naval ships — are all products of precision machining. If Africa continues to depend on imported tools, it will never achieve defense independence. A continent that cannot make its own military hardware cannot defend itself effectively in times of crisis.

This dependency forces African countries to rely on external powers for weapons, spare parts, and training — perpetuating neo-colonial influence under the guise of “defense partnerships.”

6. Environmental and Infrastructure Risks

Foreign machine tools are often designed for environments with stable electricity, clean air, and climate-controlled factories. In Africa, where power fluctuations and dust are common, imported machines frequently break down faster.

Because African engineers often lack access to the original software or proprietary parts, maintenance becomes costly and time-consuming. This not only reduces productivity but also generates large quantities of industrial waste from prematurely discarded machinery.

Locally designed machine tools could be built to withstand Africa’s environmental realities — running efficiently on variable power, using locally available materials, and being easier to repair. But without domestic production, these adaptations remain impossible.

7. Educational and Technological Risks

African universities and polytechnics often rely on imported equipment for engineering training. When these machines break down, they cannot be repaired locally because the spare parts or expertise are unavailable. This leads to abandoned workshops and outdated curricula.

By failing to develop a domestic machine tool sector, African nations risk producing generations of engineers with theoretical knowledge but limited practical skills. Meanwhile, students in countries like China, India, and South Korea gain hands-on experience designing and building their own tools — the very foundation of industrial innovation.

8. Political and Geopolitical Risks

Continued dependency on imported machine tools reinforces Africa’s peripheral position in the global economy. Instead of being a producer, the continent remains a market — valuable for its resources and consumption, but not for its technological capacity.

This limits Africa’s voice in global negotiations on trade, patents, and industrial policy. Countries that control manufacturing technology — such as Germany, Japan, or China — can shape global standards, dictate prices, and wield influence over international policy. Africa, lacking a comparable base, remains a passive participant rather than a co-architect of the global industrial system.

Moreover, dependence creates internal political vulnerability. Governments that rely heavily on imports are often pressured by foreign powers during elections, policy debates, or conflicts. Industrial weakness translates into diplomatic weakness.

9. Breaking the Cycle: The Case for Local Machine Tool Development

The risks of dependency make one thing clear — Africa must not remain a permanent importer of machine tools. Developing a local machine tool industry is not an impossible dream; it is a strategic necessity.

Steps to begin include:

-

Public investment in national machine tool research centers and training institutes.

-

Incentives for private manufacturers to produce small and medium-scale tools.

-

Regional cooperation under AfCFTA to create shared industrial hubs.

-

Technology partnerships with emerging economies (India, China, Turkey, Brazil) that emphasize knowledge transfer.

By mastering machine tools, Africa can build cars, tractors, and energy systems locally — reducing imports, saving foreign exchange, and creating millions of jobs.

Dependency Is a Hidden Form of Weakness

Africa’s reliance on imported machine tools may seem like a technical issue, but it is in fact a strategic vulnerability. It drains wealth, suppresses innovation, erodes skills, and leaves entire economies exposed to external shocks and political manipulation.

If the continent continues this path indefinitely, it risks becoming a permanent industrial colony — rich in resources, poor in technology, and dependent on foreign goodwill for its survival.

However, by investing in domestic machine tool capacity — even starting small — Africa can reverse this cycle. It can transform dependency into self-determination, and vulnerability into strength.

Control over machine tools means control over destiny. Without it, Africa builds nothing lasting; with it, Africa builds its future.

- Questions and Answers

- Opinion

- Motivational and Inspiring Story

- Technology

- Live and Let live

- Focus

- Geopolitics

- Military-Arms/Equipment

- Безопасность

- Economy

- Beasts of Nations

- Machine Tools-The “Mother Industry”

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film/Movie

- Fitness

- Food

- Игры

- Gardening

- Health

- Главная

- Literature

- Music

- Networking

- Другое

- Party

- Religion

- Shopping

- Sports

- Theater

- Health and Wellness

- News

- Culture