A Comprehensive Guide to HDPE Sheets: Properties, Uses, and Benefits

In the diverse world of materials, HDPE sheets stand out for their versatility and durability. High-Density Polyethylene (HDPE) sheets are widely used in various applications, ranging from industrial to domestic purposes. This blog will explore the properties, benefits, and applications of Hdpe sheet manufacturer in India, providing a detailed understanding of why they are a popular choice for many different uses.

What Are HDPE Sheets?

HDPE sheets are flat panels made from High-Density Polyethylene, a type of plastic known for its high strength-to-density ratio. HDPE is produced through the polymerization of ethylene, resulting in a material that is both rigid and resilient. The "high-density" in Hdpe sheet manufacturers and supplier to its molecular structure, which gives it greater strength and durability compared to other types of polyethylene.

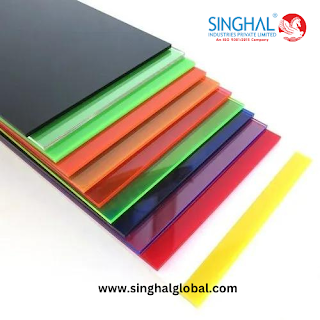

HDPE sheets come in various thicknesses, sizes, and colors, making them adaptable to a wide range of applications. They are known for their excellent impact resistance, chemical resistance, and low moisture absorption, which contributes to their long service life and reliability.

Key Properties of HDPE Sheets

HDPE sheets possess several key properties that make them suitable for numerous applications:

-

Durability: One of the most significant advantages of HDPE sheets is their durability. They are resistant to impact, wear, and tear, making them ideal for high-stress applications. This toughness ensures that HDPE sheets can withstand harsh environments and heavy use.

-

Chemical Resistance: HDPE sheets exhibit excellent resistance to a wide range of chemicals, including acids, bases, and solvents. This property makes them suitable for use in environments where exposure to corrosive substances is common.

-

Low Moisture Absorption: HDPE sheets have a low moisture absorption rate, which means they do not swell or degrade when exposed to water. This characteristic is particularly valuable in applications where moisture resistance is critical.

-

Lightweight: Despite their strength, HDPE sheets are relatively lightweight. This makes them easier to handle and install, reducing transportation and installation costs.

-

Flexibility: HDPE sheets are flexible and can be easily fabricated or cut to fit specific requirements. They can be thermoformed or machined to create custom shapes and sizes.

-

UV Resistance: HDPE sheets are resistant to ultraviolet (UV) radiation, which helps prevent degradation from sun exposure. This property is beneficial for outdoor applications where UV exposure is a concern.

Benefits of HDPE Sheets

The benefits of using HDPE sheets extend across various industries and applications:

-

Cost-Effectiveness: HDPE sheets offer a cost-effective solution for many applications due to their durability and low maintenance requirements. Their long service life and resistance to damage reduce the need for frequent replacements.

-

Ease of Fabrication: The flexibility of HDPE sheets allows for easy fabrication, including cutting, welding, and machining. This adaptability makes them suitable for custom applications and modifications.

-

Hygienic Properties: HDPE sheets are non-porous and easy to clean, making them ideal for use in environments that require high hygiene standards, such as food processing and medical facilities.

-

Environmental Impact: HDPE is recyclable, which helps reduce environmental impact. Many HDPE sheets are made from recycled materials, contributing to a circular economy and reducing waste.

-

Versatility: The wide range of sizes, thicknesses, and colors available for HDPE sheets allows them to be used in a variety of applications, from industrial to residential.

Applications of HDPE Sheets

HDPE sheets are used in a broad spectrum of applications across different industries:

-

Construction: In the construction industry, HDPE sheets are used for waterproofing, lining, and insulation. They are often employed in foundations, retaining walls, and as a barrier in underground construction to protect structures from moisture.

-

Manufacturing: HDPE sheets are used in manufacturing processes for creating custom parts, machinery components, and industrial equipment. Their durability and ease of fabrication make them suitable for high-wear applications.

-

Food Processing: The hygienic properties of HDPE sheets make them ideal for use in food processing facilities. They are used for cutting boards, conveyor belts, and storage containers, where cleanliness and safety are paramount.

-

Agriculture: In agriculture, HDPE sheets are utilized for lining ponds, building greenhouses, and creating protective barriers for crops. Their resistance to moisture and chemicals makes them valuable in various agricultural applications.

-

Marine: HDPE sheets are employed in marine environments for applications such as boat hulls, dock components, and marine barriers. Their resistance to water and UV radiation makes them suitable for exposure to harsh marine conditions.

-

Environmental Protection: HDPE sheets are used in environmental protection applications, including landfill liners and environmental barriers. Their durability and resistance to chemical leaching help prevent contamination and manage waste.

Installation and Maintenance of HDPE Sheets

Proper installation and maintenance of HDPE sheets are essential to ensure their longevity and performance:

-

Installation: HDPE sheets can be installed using various methods, including mechanical fastening, adhesive bonding, and welding. The choice of method depends on the specific application and the conditions of use. It is important to follow manufacturer guidelines for installation to achieve the best results.

-

Maintenance: HDPE sheets require minimal maintenance due to their resistance to stains and easy cleaning. Regular cleaning with mild soap and water is usually sufficient to maintain their appearance and performance. For industrial applications, periodic inspections may be necessary to check for any signs of wear or damage.

Environmental Considerations

While HDPE sheets offer several environmental benefits, including recyclability and long service life, it is important to consider their overall impact:

-

Recycling: HDPE is widely recyclable, and many HDPE sheets are made from recycled materials. Recycling helps reduce waste and conserve resources. Proper disposal and recycling practices contribute to environmental sustainability.

-

Sustainability: The use of HDPE sheets in various applications can support sustainability efforts by providing durable, long-lasting solutions. Reducing the need for frequent replacements and minimizing maintenance contributes to resource conservation.

Conclusion

HDPE sheets are a versatile and durable material used across a wide range of applications. Their key properties, including durability, chemical resistance, and low moisture absorption, make them suitable for industrial, agricultural, and environmental uses. The benefits of Hdpe sheets 4x8 manufacturer, such as cost-effectiveness, ease of fabrication, and hygienic properties, further enhance their appeal.

By understanding the properties, benefits, and applications of HDPE sheets, businesses and individuals can make informed decisions and utilize this material effectively. As industries continue to seek reliable and sustainable solutions, HDPE sheets will remain a valuable choice for a variety of needs.

Frequently Asked Questions (FAQs):

What makes Singhal Industries' HDPE sheets stand out from other options available in the market?

Singhal Industries' HDPE sheets are distinguished by their superior durability, versatility, and high-performance characteristics. These sheets are made from high-density polyethylene, offering exceptional strength and resistance to impact, chemicals, and moisture. Singhal Industries ensures that their HDPE sheets meet rigorous quality standards, providing a reliable solution for various industrial, agricultural, and environmental applications. The flexibility of these sheets also allows for easy fabrication and customization, making them suitable for a wide range of uses. Additionally, Singhal Industries’ commitment to using high-quality raw materials and advanced manufacturing processes contributes to the overall excellence of their HDPE sheets.

How does Singhal Industries ensure the environmental sustainability of their HDPE sheets?

Singhal Industries is dedicated to environmental sustainability in the production of their HDPE sheets. The company emphasizes the recyclability of HDPE, ensuring that their sheets can be effectively recycled at the end of their lifecycle. By incorporating recycled materials into their production processes, Singhal Industries contributes to reducing environmental impact and conserving resources. Additionally, the durability and long service life of their HDPE sheets help to minimize waste and the need for frequent replacements. Singhal Industries is also actively exploring further sustainable practices and materials to enhance the environmental benefits of their products.

What are the typical applications of Singhal Industries' HDPE sheets, and how do they benefit different industries?

Singhal Industries' HDPE sheets are utilized across a diverse range of industries due to their robust properties and adaptability. In the construction industry, they are used for applications such as waterproofing and insulation, providing reliable protection against moisture and environmental stress. The food processing sector benefits from the hygienic and easy-to-clean nature of these sheets, which are ideal for surfaces and storage solutions. In agriculture, Singhal Industries' HDPE sheets are employed for lining ponds and building greenhouses, offering durability and resistance to harsh conditions. Their versatility extends to marine and environmental applications as well, where the sheets are used for protective barriers and liners, ensuring longevity and performance in challenging environments.

- Questions and Answers

- Opinion

- Motivational and Inspiring Story

- Technology

- Live and Let live

- Focus

- Geopolitics

- Military-Arms/Equipment

- Segurança

- Economy

- Beasts of Nations

- Machine Tools-The “Mother Industry”

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film/Movie

- Fitness

- Food

- Jogos

- Gardening

- Health

- Início

- Literature

- Music

- Networking

- Outro

- Party

- Religion

- Shopping

- Sports

- Theater

- Health and Wellness

- News

- Culture