Exploring HDPE Sheets: Applications, Benefits, and Versatility

High-Density Polyethylene (HDPE) sheets are a popular material known for their exceptional strength, durability, and versatility. Made from a type of plastic that offers superior resistance to impact, chemicals, and environmental conditions, HDPE sheets are used in a wide range of industries and applications. This blog will explore the features, benefits, Hdpe sheet manufacturer in India, and considerations of HDPE sheets, providing a comprehensive look at why they are a valuable material in both industrial and everyday uses.

What Are HDPE Sheets?

HDPE sheets are made from high-density polyethylene, a thermoplastic polymer characterized by its high strength-to-density ratio. This material is known for its resilience and ability to withstand various environmental factors. HDPE sheets are produced through an extrusion process, where polyethylene pellets are melted and formed into flat sheets. The result is a robust, flexible material that can be used in a variety of applications.

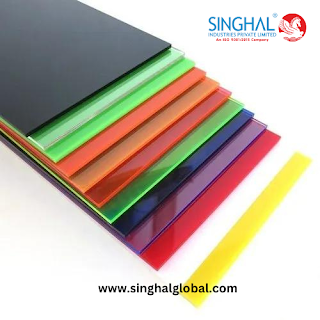

The sheets are available in different thicknesses, sizes, and colors, allowing for customization to meet specific Hdpe sheet manufacturers and supplier. They are also available in various grades, including standard and custom formulations, to enhance their performance in different environments.

Key Features of HDPE Sheets

1. Strength and Durability: HDPE sheets are known for their high impact resistance and durability. They can withstand heavy loads and rough handling without cracking or breaking. This strength makes them suitable for demanding applications.

2. Chemical Resistance: HDPE is highly resistant to a wide range of chemicals, including acids, bases, and solvents. This property makes HDPE sheets ideal for use in environments where exposure to chemicals is a concern.

3. Weather Resistance: HDPE sheets are resistant to UV radiation, moisture, and temperature extremes. This weather resistance ensures that the material maintains its integrity and performance even in harsh outdoor conditions.

4. Lightweight: Despite their strength, HDPE sheets are relatively lightweight compared to other materials with similar properties. This characteristic makes them easier to handle and install.

5. Low Friction: The low friction surface of HDPE sheets reduces wear and tear on equipment and reduces the likelihood of abrasion. This feature is particularly useful in applications involving moving parts or machinery.

6. Easy Maintenance: HDPE sheets are easy to clean and maintain. Their non-porous surface prevents the accumulation of dirt and grime, making them hygienic and easy to keep in good condition.

Benefits of Using HDPE Sheets

1. Cost-Effectiveness: HDPE sheets offer excellent performance at a relatively low cost. Their durability and long lifespan make them a cost-effective choice for various applications, reducing the need for frequent replacements.

2. Versatility: The adaptability of HDPE sheets allows them to be used in a wide range of applications. They can be cut, drilled, and shaped to meet specific requirements, making them a versatile material for many industries.

3. Environmental Impact: HDPE sheets are recyclable, which helps reduce their environmental impact. Many HDPE products are made from recycled materials, contributing to a more sustainable approach to manufacturing.

4. Ease of Fabrication: HDPE sheets can be easily fabricated using standard tools and techniques. They can be welded, thermoformed, and machined to create custom shapes and designs.

5. Safe and Non-Toxic: HDPE is a non-toxic material that does not release harmful chemicals into the environment. This safety feature makes HDPE sheets suitable for applications in food processing, medical devices, and other sensitive areas.

Applications of HDPE Sheets

1. Industrial Applications: HDPE sheets are widely used in industrial settings for creating equipment liners, chutes, and conveyor components. Their resistance to wear and tear makes them ideal for handling abrasive materials and harsh environments.

2. Construction: In the construction industry, HDPE sheets are used as vapor barriers, insulation materials, and protective membranes. They provide effective moisture control and protection against environmental elements.

3. Packaging: HDPE sheets are used in packaging applications, including the manufacture of containers, pallets, and protective barriers. Their strength and chemical resistance make them suitable for packaging hazardous materials and chemicals.

4. Environmental Solutions: HDPE sheets are used in environmental applications such as liners for landfills and ponds. Their resistance to chemical leaching and weathering makes them effective at containing waste and preventing contamination.

5. Signage and Display: HDPE sheets are commonly used for outdoor signage and display panels. Their weather resistance and durability ensure that the signs remain legible and intact even in challenging conditions.

6. Agriculture: In agriculture, HDPE sheets are used for greenhouse coverings, irrigation systems, and protective barriers. Their resistance to UV radiation and moisture makes them suitable for agricultural applications.

7. Transportation: HDPE sheets are utilized in transportation for creating truck liners, cargo barriers, and vehicle components. Their impact resistance helps protect vehicles and cargo during transit.

Considerations When Using HDPE Sheets

1. Temperature Limitations: While HDPE sheets are resistant to a wide range of temperatures, they can become brittle at extremely low temperatures. It is important to consider the temperature conditions of the application when selecting HDPE sheets.

2. Surface Scratching: The surface of HDPE sheets can be prone to scratching, especially in high-traffic areas. While this does not affect the overall performance, it may impact the appearance of the material.

3. Joining Methods: When joining HDPE sheets, it is important to use appropriate methods such as welding or adhesive bonding. Standard adhesives may not work effectively with HDPE, so specialized products designed for plastic bonding should be used.

4. Chemical Compatibility: Although HDPE sheets are resistant to many chemicals, it is important to verify compatibility with specific substances used in the application. Some aggressive chemicals may still affect the material.

5. Environmental Conditions: HDPE sheets should be selected based on the environmental conditions they will be exposed to. Factors such as UV exposure, moisture levels, and temperature extremes should be considered to ensure optimal performance.

Conclusion

HDPE sheets are a highly versatile and durable material used in a wide range of applications across various industries. Their strength, chemical resistance, and weather resistance make them an excellent choice for demanding environments. Whether used in industrial settings, construction, packaging, or environmental solutions, HDPE sheets offer a cost-effective and reliable solution for many needs.

As a leading manufacturer, Singhal Industries provides high-quality HDPE sheets that meet industry standards for performance and durability. By focusing on innovation and quality, Singhal Industries Hdpe sheets 4x8 manufacturer that its products deliver exceptional results and meet the diverse needs of its customers. With their versatility and robustness, HDPE sheets continue to be a valuable material in both industrial and everyday applications, contributing to efficiency and effectiveness in numerous fields.

Frequently Asked Questions (FAQs):

1. How does Singhal Industries ensure the quality of its HDPE sheets?

Singhal Industries maintains high-quality standards for its HDPE sheets through stringent manufacturing processes and rigorous quality control measures. The company utilizes advanced production technologies and high-grade polyethylene materials to ensure that each sheet is strong, durable, and meets industry specifications. Comprehensive testing is conducted to assess the sheets' resistance to impact, chemicals, and environmental conditions, guaranteeing that Singhal Industries' HDPE sheets perform reliably in various applications.

2. What customization options are available for HDPE sheets from Singhal Industries?

Singhal Industries offers a range of customization options for HDPE sheets to meet specific customer needs. The company provides various thicknesses, sizes, and colors, allowing businesses to select the ideal sheet for their application. Additionally, Singhal Industries can accommodate special requirements such as custom formulations for enhanced performance and specific surface finishes. This flexibility ensures that customers receive HDPE sheets tailored to their precise specifications and intended uses.

3. How does Singhal Industries address environmental concerns with its HDPE sheets?

Singhal Industries is committed to minimizing the environmental impact of its HDPE sheets by promoting recycling and sustainability. The company incorporates recycled materials into its production processes and supports recycling programs to manage plastic waste effectively. Singhal Industries also explores and invests in environmentally friendly practices and alternative materials to further reduce the ecological footprint of its products. These efforts reflect the company's dedication to environmental responsibility and sustainability in its manufacturing practices.

- Questions and Answers

- Opinion

- Motivational and Inspiring Story

- Technology

- Live and Let live

- Focus

- Geopolitics

- Military-Arms/Equipment

- Security

- Economy

- Beasts of Nations

- Machine Tools-The “Mother Industry”

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film/Movie

- Fitness

- Food

- Games

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Health and Wellness

- News

- Culture