A Comprehensive Guide to HDPE Sheets: Benefits, Uses, and Considerations

High-Density Polyethylene (HDPE) sheets are a versatile and durable material widely used across various industries. Known for their excellent chemical resistance, strength, and versatility, HDPE sheets are an invaluable resource for many applications. This blog will explore what Hdpe sheet manufacturer in India are, their advantages, common uses, and important considerations when choosing the right sheet for your needs.

What Are HDPE Sheets?

HDPE sheets are made from high-density polyethylene, a type of plastic polymer known for its robustness and high strength-to-density ratio. Polyethylene is categorized into different types based on its density and molecular structure, with HDPE being one of the Hdpe sheet manufacturers and supplier and versatile forms. HDPE sheets are produced through a process where polyethylene resin is extruded into flat sheets, which are then cut to size as required.

Key Benefits of HDPE Sheets

HDPE sheets offer several benefits that make them a popular choice for various applications:

Durability and Strength

HDPE sheets are renowned for their exceptional durability. They have a high tensile strength, making them resistant to impact and wear. This durability makes HDPE sheets suitable for applications where strength and longevity are crucial.

Chemical Resistance

One of the standout features of HDPE sheets is their resistance to a wide range of chemicals. They are highly resistant to acids, bases, and solvents, making them ideal for use in chemical processing, storage, and handling environments.

Weather Resistance

HDPE sheets perform well under various weather conditions. They are resistant to UV radiation, moisture, and extreme temperatures, which ensures their stability and longevity in outdoor or harsh environments.

Low Maintenance

HDPE sheets are relatively low maintenance. They do not require frequent cleaning or special treatments to maintain their properties. Their smooth surface is easy to clean, and they are resistant to staining and scratching.

Lightweight and Flexible

Despite their strength, HDPE sheets are lightweight and flexible. This makes them easy to handle and install, reducing labor and transportation costs. The flexibility of HDPE sheets also allows for easy cutting and shaping to fit specific needs.

Cost-Effectiveness

HDPE sheets offer excellent value for money. They are cost-effective compared to many other materials with similar properties. Their long lifespan and minimal maintenance requirements contribute to their overall affordability.

Common Uses of HDPE Sheets

HDPE sheets are used in a wide variety of applications across different industries:

Construction

In the construction industry, HDPE sheets are used for applications such as damp proofing, lining, and as a barrier material. They are employed in foundation work to prevent moisture infiltration and are used in construction for their durability and resistance to environmental factors.

Agriculture

HDPE sheets are commonly used in agriculture for applications like pond liners, greenhouse covers, and silage wraps. Their chemical resistance and durability make them suitable for handling fertilizers, pesticides, and other agricultural chemicals.

Chemical and Pharmaceutical Industries

In the chemical and pharmaceutical sectors, HDPE sheets are used for creating storage tanks, containers, and linings. Their chemical resistance ensures the safe handling and storage of various chemicals and pharmaceuticals.

Food Industry

HDPE sheets are utilized in the food industry for cutting boards, trays, and containers. Their non-porous surface makes them easy to clean and sanitize, which is crucial for maintaining hygiene and safety standards.

Manufacturing

HDPE sheets are used in various manufacturing applications, including the production of components, machinery parts, and protective barriers. Their versatility and ease of fabrication make them suitable for custom manufacturing needs.

Environmental Protection

HDPE sheets are employed in environmental protection projects, such as landfill liners and containment barriers. They help prevent soil and water contamination by providing a durable and impermeable layer.

Considerations for Choosing the Right HDPE Sheet

When selecting HDPE sheets for your project or application, several factors should be considered to ensure you choose the right material:

Thickness and Size

HDPE sheets come in various thicknesses and sizes. Determine the thickness required based on the mechanical and environmental stresses the sheet will face. Additionally, choose the size of the sheet based on your project's specifications and installation requirements.

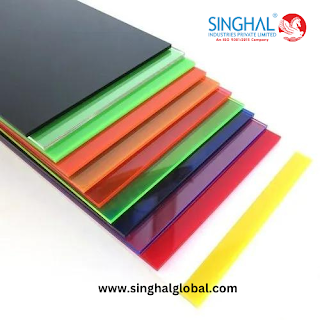

Color and Finish

HDPE sheets are available in a range of colors and finishes. While the color may not always affect performance, it can impact aesthetics and visibility. For specific applications, such as food contact or chemical handling, consider the appropriate color and finish to meet industry standards.

Temperature Tolerance

Consider the temperature range that the HDPE sheets will be exposed to. While HDPE sheets perform well under a range of temperatures, some applications may require sheets with enhanced temperature resistance. Check the manufacturer's specifications for temperature tolerance to ensure suitability for your application.

Fabrication and Customization

HDPE sheets can be fabricated and customized to fit specific needs. If your project requires custom shapes, cuts, or additional features, work with a supplier who can provide fabrication services to meet your requirements.

Regulatory Compliance

Ensure that the HDPE sheets meet relevant industry standards and regulations. For applications in the food and pharmaceutical industries, check for compliance with health and safety regulations to ensure the sheets are suitable for your intended use.

Environmental Impact

While HDPE sheets are durable and long-lasting, consider their environmental impact. Polyethylene is a plastic material that does not biodegrade easily. Look for suppliers that offer recycling options or consider using HDPE sheets in applications where their longevity can help mitigate environmental concerns.

Environmental Considerations

The environmental impact of HDPE sheets is an important consideration. Although HDPE is a recyclable material, its disposal and recycling can present challenges. Here are some strategies to address environmental concerns:

Recycling Programs

Participate in recycling programs for HDPE sheets. Many plastic products, including HDPE, can be recycled. Ensure that you follow local recycling guidelines and dispose of HDPE sheets properly to reduce waste.

Reusability

Maximize the lifespan of HDPE sheets by reusing them whenever possible. Their durability and resistance to wear make them suitable for multiple uses, which can help reduce the need for new materials and minimize environmental impact.

Sustainable Practices

Explore sustainable practices and alternative materials where possible. Consider using HDPE sheets in applications that benefit from their longevity and durability, and investigate options for incorporating recycled content into new HDPE sheets.

Conclusion

HDPE sheets are a versatile and durable material with a wide range of applications across various industries. Their strength, chemical resistance, and weather resistance make them a valuable resource for many projects, from construction and agriculture to manufacturing and environmental Hdpe sheets 4x8 manufacturer When choosing HDPE sheets, consider factors such as thickness, color, temperature tolerance, and regulatory compliance to ensure you select the right material for your needs. By addressing environmental considerations and adopting responsible practices, you can effectively utilize HDPE sheets while contributing to a more sustainable future.

Frequently Asked Questions (FAQs):

What makes Singhal Industries' HDPE sheets stand out from other brands?

Singhal Industries' HDPE sheets are distinguished by their exceptional durability and strength. Manufactured using high-quality polyethylene, these sheets offer superior resistance to impacts, chemicals, and weather conditions. Singhal Industries ensures that their HDPE sheets meet stringent quality standards, making them a reliable choice for various applications including construction, agriculture, and manufacturing.

How does Singhal Industries ensure the environmental responsibility of their HDPE sheets?

Singhal Industries is committed to environmental responsibility by focusing on recycling and sustainability. The company provides guidance on the proper disposal and recycling of HDPE sheets, helping to reduce environmental impact. Additionally, Singhal Industries explores options for incorporating recycled materials into their products and adheres to best practices in minimizing the ecological footprint of their operations.

What types of applications are suitable for Singhal Industries' HDPE sheets?

Singhal Industries' HDPE sheets are versatile and suitable for a wide range of applications. They are commonly used in construction for damp proofing and lining, in agriculture for pond liners and greenhouse covers, and in the chemical industry for storage and containment. Their strength and chemical resistance make them ideal for various industries requiring durable and reliable sheet solutions.

- Questions and Answers

- Opinion

- Motivational and Inspiring Story

- Technology

- Live and Let live

- Focus

- Geopolitics

- Military-Arms/Equipment

- Segurança

- Economy

- Beasts of Nations

- Machine Tools-The “Mother Industry”

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film/Movie

- Fitness

- Food

- Jogos

- Gardening

- Health

- Início

- Literature

- Music

- Networking

- Outro

- Party

- Religion

- Shopping

- Sports

- Theater

- Health and Wellness

- News

- Culture