Milling Machine Market: Trends, Growth, and Forecast (2025-2033)

The global milling machine market size attained a value of USD 84.26 billion in 2024. The milling machine market is further expected to grow in the forecast period of 2025-2033 at a CAGR of 7.2%, reaching USD 157.02 billion by 2033. As industries continue to evolve, the demand for advanced manufacturing tools like milling machines is expected to surge. Milling machines, known for their precision and versatility, are integral to a variety of sectors, including automotive, aerospace, defense, and construction. The Asia Pacific region stands out as the fastest-growing market, driven by rapid industrialization, the expansion of manufacturing industries, and increasing demand for automation and precision machinery.

In this blog post, we will explore the key segments of the global milling machine market, focusing on the mechanisms, directions, and applications that are driving growth. We will also take a closer look at regional trends, market dynamics, and competitive strategies shaping the future of the industry.

Market Segmentation

By Mechanism

Milling machines can be categorized based on their mechanisms, which determine how they interact with the materials being processed. The two primary types of milling machines in this market are fraction rice milling machines and grind rice milling machines.

Fraction Rice Milling Machines

Fraction rice milling machines are widely used in food processing, particularly in rice milling, where the goal is to separate the outer husk from the rice grain without breaking it. These machines are designed to efficiently separate the rice bran and husk while retaining the quality of the rice kernel. Due to their high efficiency and accuracy, they are extensively used in rice-producing countries for large-scale milling operations. Additionally, fraction rice milling machines are expanding their presence in emerging economies, where the demand for rice milling is increasing rapidly.

Grind Rice Milling Machines

Grind rice milling machines are designed to process grains by grinding them into smaller particles. These machines are often used in industries where finer particle sizes are required, such as in the production of flour or powdered grains. The process involves a series of grinders and mills that break down the grains into the desired texture. These machines are commonly used in food processing, but they also find applications in other sectors like pharmaceuticals and chemicals.

By Direction

The direction in which the mill rollers operate plays a crucial role in the efficiency and precision of the milling process. Milling machines are generally classified into vertical type mill rollers and horizontal mill rollers.

Vertical Type Mill Rollers

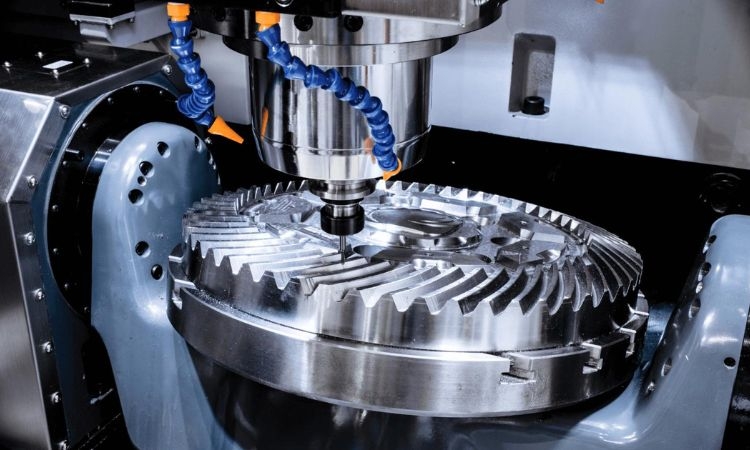

Vertical type mill rollers are designed to work in a vertical orientation, where the material is fed downward through a rotating roller mechanism. This type of milling machine is particularly suited for precision applications, such as in aerospace, automotive, and defense manufacturing. Vertical mills offer several advantages, including better surface finish quality, high precision, and the ability to handle complex geometries. These mills are commonly used for high-performance applications requiring exacting standards.

Horizontal Mill Rollers

In contrast, horizontal mill rollers work by rotating in a horizontal plane, with the material fed across the roller in a side-to-side motion. Horizontal mills are typically used in large-scale manufacturing processes where high material removal rates are required. These machines are ideal for operations such as machining flat parts or components that require heavy cutting and milling. They are also preferred in industries where high productivity and efficiency are key.

By End Use

Milling machines find applications in a wide variety of industries, from automotive and aerospace to construction and defense. The flexibility of these machines makes them indispensable across multiple sectors.

Automotive

In the automotive industry, milling machines are extensively used for manufacturing critical components such as engine parts, transmission systems, and chassis. Milling provides high precision, which is essential for the performance and safety of vehicles. As the automotive sector continues to innovate with electric vehicles (EVs) and advanced driver-assistance systems (ADAS), the demand for high-precision milling machines will continue to grow. Automation trends and the push for lightweight materials further drive this market segment.

Aerospace and Defense

The aerospace and defense sectors require extremely high standards of precision, durability, and reliability for components such as aircraft parts, missile systems, and defense equipment. Milling machines are essential for producing complex, high-tolerance parts that meet these demanding specifications. As defense budgets increase globally, and with ongoing advancements in aerospace technology, the demand for milling machines in this sector is expected to rise significantly.

Construction Equipment

Milling machines are also vital in the construction equipment industry, where they are used to manufacture heavy machinery components. These machines are instrumental in producing robust parts used in bulldozers, cranes, excavators, and other construction vehicles. With infrastructure development projects gaining momentum in emerging markets, particularly in the Asia-Pacific region, the demand for milling machines in the construction industry is poised to increase.

Others

In addition to the primary sectors above, milling machines are also employed in industries such as electronics, pharmaceuticals, and industrial equipment manufacturing. The versatility of these machines makes them applicable in a wide range of manufacturing processes, from creating precision components in electronics to producing industrial machinery.

Regional Analysis

The milling machine market is geographically diverse, with varying growth rates and opportunities in different regions.

North America

North America is a significant player in the global milling machine market, particularly in the United States. The automotive, aerospace, and defense industries in the region are among the largest consumers of milling machines, driving substantial demand. Moreover, advanced manufacturing technologies, including automation and robotics, are becoming more prevalent, further boosting the market for milling machines. With a strong industrial base and focus on innovation, North America remains a key market for high-precision milling machines.

Europe

Europe is another dominant market for milling machines, driven by strong industrial sectors such as automotive manufacturing, aerospace, and defense. Countries like Germany, the UK, and France are at the forefront of adopting advanced machining technologies, including CNC milling machines. The demand for milling machines is also supported by Europe’s commitment to green energy and the automotive sector’s transition to electric vehicles, both of which require precise and innovative manufacturing solutions.

Asia-Pacific

The Asia-Pacific (APAC) region is the fastest-growing market for milling machines, fueled by rapid industrialization and increased manufacturing activities. Countries like China, Japan, India, and South Korea are key contributors to the demand for milling machines, particularly in industries such as automotive, aerospace, and electronics. The region’s burgeoning infrastructure projects and the expansion of the industrial base are driving significant growth in the milling machine market. As automation and digitalization gain momentum, the demand for advanced milling machines in the APAC region is set to continue its rapid ascent.

Rest of the World

The Rest of the World, including regions such as Latin America, the Middle East, and Africa, is also witnessing growth in milling machine demand, albeit at a slower pace compared to other regions. However, with infrastructure development on the rise, particularly in the Middle East and Latin America, there is potential for significant market growth in these regions. As industrialization picks up, milling machine adoption is expected to increase in these emerging economies.

Market Dynamics

Drivers

- Industrial Growth: The increasing demand for high-performance, precise components in sectors like automotive, aerospace, and defense is one of the major drivers of the milling machine market.

- Technological Advancements: The evolution of milling machines, including the integration of automation, robotics, and digital technologies, is expanding their capabilities and boosting their adoption.

- Rising Demand for Precision Manufacturing: As industries push for higher quality and more complex components, the need for precise milling machines continues to grow.

Restraints

- High Initial Costs: The capital-intensive nature of milling machines, particularly advanced systems, can deter smaller manufacturers from investing in these machines.

- Skill Gap: The need for skilled operators to run advanced milling machines remains a challenge, particularly as automation and digital systems become more prevalent.

Opportunities

- Automation and Smart Manufacturing: The growing trend toward automation in industries like automotive and aerospace presents significant opportunities for milling machine manufacturers to offer more integrated, smart solutions.

- Expansion in Emerging Markets: With the industrialization of regions like Asia-Pacific, Latin America, and the Middle East, there are substantial growth opportunities for milling machines.

Challenges

- Environmental Concerns: The manufacturing process involved in milling machines can be energy-intensive, and there is growing pressure for companies to adopt more sustainable practices.

- Supply Chain Issues: Global supply chain disruptions could potentially impact the availability and cost of raw materials required for manufacturing milling machines.

Competitive Landscape

The global milling machine market is highly competitive, with several key players dominating the industry. Leading companies include:

- DMG Mori: A global leader in machine tools and CNC milling machines, offering a wide range of high-precision machines.

- Mazak Corporation: Known for innovative CNC machine tools, Mazak offers advanced solutions for various industries, including aerospace and automotive.

- Haas Automation: One of the most recognized brands in CNC machining, providing versatile and cost-effective milling solutions.

- Hurco Companies: A leader in manufacturing CNC machines that are highly customizable for a wide range of applications.

These companies focus on innovations such as automation, 3D milling, and multi-axis machines to stay ahead in the competitive market.

- Questions and Answers

- Opinion

- Motivational and Inspiring Story

- Technology

- Live and Let live

- Focus

- Geopolitics

- Military-Arms/Equipment

- Segurança

- Economy

- Beasts of Nations

- Machine Tools-The “Mother Industry”

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film/Movie

- Fitness

- Food

- Jogos

- Gardening

- Health

- Início

- Literature

- Music

- Networking

- Outro

- Party

- Religion

- Shopping

- Sports

- Theater

- Health and Wellness

- News

- Culture