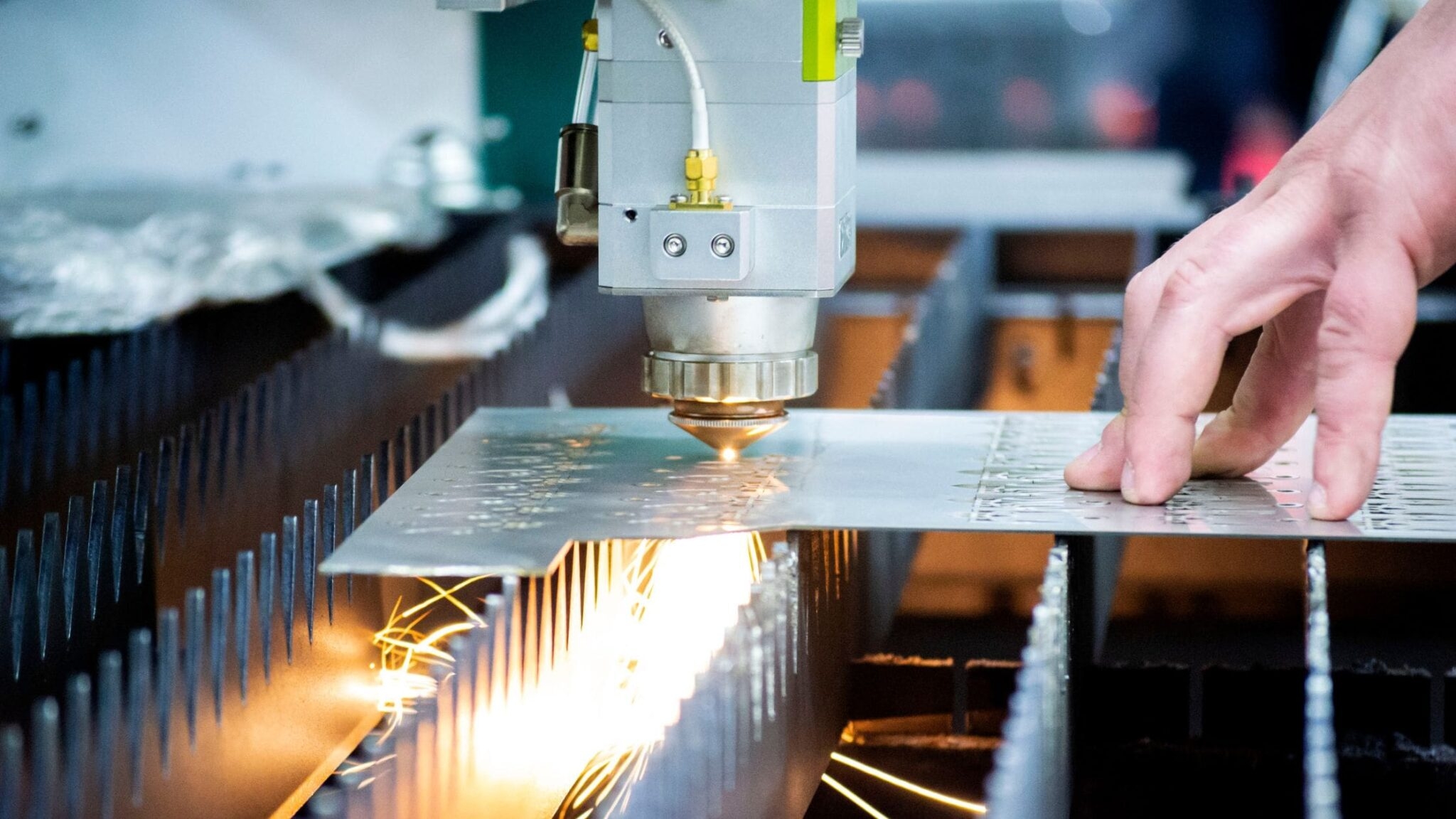

Choose the Right Fiber Laser Cutting Machine

Selecting the right fiber laser cutting machine is crucial for maximizing efficiency, precision, and profitability in your production processes. Here’s a guide on how to choose the best fiber laser cutting machine based on your needs:

1. Understand Your Cutting Requirements

Determine which materials you'll be cutting (steel, stainless steel, aluminum, copper, etc.). Fiber lasers are versatile and can cut a wide range of metals but perform differently on different materials. Fiber lasers can cut materials of varying thicknesses, so choose a machine with appropriate power. For example:

1. Thin Materials (up to 1mm): A machine with lower power (500W - 1kW) is suitable.

2. Medium Thickness (1mm to 6mm): Machines with power between 1kW and 3kW work best.

3. Thick Materials (6mm and above): Higher-power lasers (4kW to 12kW) are needed to cut thicker materials effectively.

If your production requires high-speed cutting or precise cuts, choose a machine that offers high accuracy and fast processing capabilities.

2. Consider Power Requirements

The power of the fiber laser (measured in watts, W) directly impacts cutting speed and material thickness. Higher power allows for faster cutting and the ability to handle thicker materials. Fiber lasers are generally more energy-efficient than CO2 lasers. Still, ensure the laser power matches your typical cutting needs to optimize energy consumption.

3. Choose the Right Size and Working Area

The cutting bed size should accommodate the largest material size you intend to process. Common sizes include 1.5m x 3m and 2m x 4m. If you're working with large sheets or cutting larger components, opt for a machine with a larger bed size. Some fiber laser cutting machine come with automatic loading and unloading systems, which can improve productivity and reduce labor costs.

4. Look at the Cutting Head and Focus Mechanism

The cutting head is an essential component that influences the precision and quality of your cuts. Look for a machine with:

Autofocus Cutting Head: This allows for automatic adjustments of the focus to adapt to different material thicknesses and types.

Focusing Lenses: Choose machines that use high-quality lenses and offer easy access for maintenance.

5. Consider Maintenance and Serviceability

Fiber lasers require less maintenance than CO2 lasers, but regular upkeep is still necessary to ensure performance. Make sure the machine is easy to maintain and repair. Consider the availability of support from the manufacturer or dealer. Choose a company that offers good customer service, technical support, and training.

6. Assess the Control System and Software Compatibility

The laser cutter should have a reliable CNC control system that’s compatible with your existing CAD/CAM software. A user-friendly interface allows for more intuitive operation and quick setup. Check for software that can easily handle different file types, optimize cutting paths, and improve overall workflow efficiency. Integration with your production management system can also streamline processes.

7. Evaluate Build Quality and Reliability

A robust machine frame ensures better accuracy and reduces vibration, leading to more precise cuts. Research the manufacturer’s reputation and reviews to ensure that the machine is durable and built to high-quality standards.

8. Budget and Total Cost of Ownership (TCO)

Compare the prices of different machines, but keep in mind that the cheapest option may not always be the best in terms of long-term value. Factor in the cost of consumables (nozzles, lenses), maintenance, and power consumption when calculating the total cost of ownership. Consider the machine’s potential to increase productivity and reduce downtime. A higher upfront cost might be justifiable if it provides long-term cost savings and efficiency.

9. Laser Type (Single or Multi-mode Fiber)

Single-mode Fiber Laser, Offers better beam quality and precision, ideal for fine cutting and high-precision tasks.Generally cheaper and suitable for cutting thicker materials at faster speeds but may not offer the same precision as a single-mode laser.

10. Safety Features

Ensure the machine includes safety features like proper shielding, emergency stop buttons, and smoke extraction systems to maintain a safe working environment.

Conclusion

When selecting the right fiber laser cutting machine from Supreme Technologies, focus on matching the machine's capabilities with your specific cutting requirements, including material type, thickness, cutting speed, and precision. Consider the total cost of ownership, including energy efficiency and maintenance, and ensure that you have access to strong after-sales support and service. By carefully assessing these factors, you can find the machine that best suits your needs, ensuring maximum productivity and value.

- Questions and Answers

- Opinion

- Motivational and Inspiring Story

- Technology

- Live and Let live

- Focus

- Geopolitics

- Military-Arms/Equipment

- Sicherheit

- Economy

- Beasts of Nations

- Machine Tools-The “Mother Industry”

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film/Movie

- Fitness

- Food

- Spiele

- Gardening

- Health

- Startseite

- Literature

- Music

- Networking

- Andere

- Party

- Religion

- Shopping

- Sports

- Theater

- Health and Wellness

- News

- Culture